Self-induction magnetic bearing

A magnetic bearing and self-induction technology, applied in bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of increasing system cost and volume, high manufacturing cost, and high friction power consumption of mechanical bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

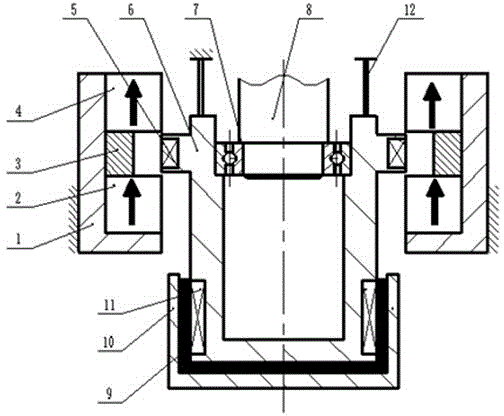

[0015] In order to make the content of the present invention easier to be understood clearly, the following further describes the present invention in detail based on specific embodiments in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a self-induction magnetic bearing includes:

[0017] At least one magnetic pair assembly, which includes an upper permanent magnet ring 4, a magnetic isolation washer 3, and a lower permanent magnet ring 2. The magnetic isolation washer 3 is arranged between the upper permanent magnet ring 4 and the lower permanent magnet ring 2 for its Used to separate the upper permanent magnet ring 4 and the lower permanent magnet ring 2, the upper permanent magnet ring 4 and the lower permanent magnet ring 2 are both axially magnetized, and the upper permanent magnet ring 4 and the lower permanent magnet ring 2 are respectively connected with the magnetic isolation washer 3 The contacting side is the opposite magnetic pole; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com