Magneto-rheological damper with effective full-damping channel

A magnetorheological damper and damper technology, applied in the field of damping and vibration reduction, can solve the problems of increasing the volume and weight of the damper, reducing the maximum output of the magnetorheological damper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

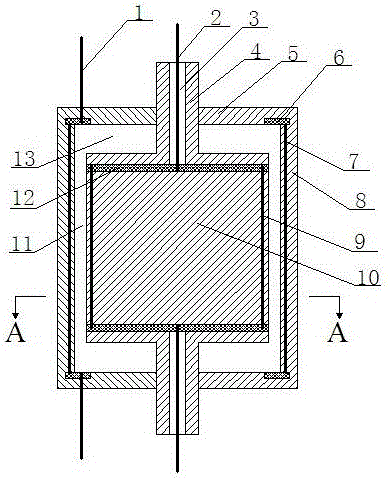

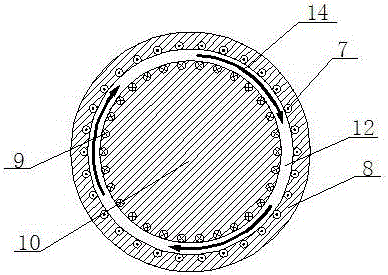

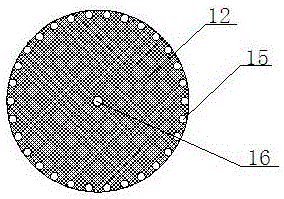

[0018] Such as figure 1 , 2 , 3, and 4, the effective magneto-rheological damper of the full damping channel includes a damper cylinder 8 and a piston body 10, the upper and lower ends of the damper cylinder are fixedly connected with end caps 5 by bolts, and the piston body is set Inside the damper cylinder and symmetrically installed at both ends are piston rods 4 protruding from both ends of the damper cylinder. The piston rod and the piston body are fixedly connected by bolts. The central axis of the piston rod, the piston body and the damper cylinder Coincident; the upper and lower parts of the piston body are symmetrically arranged with a disc-shaped hub A12 along the axis of the piston body, the diameter of the hub A is slightly smaller than the diameter of the piston body, and the outer edges of the two hubs A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com