Conveniently-reversed ratchet mechanism

A ratchet mechanism and ratchet technology, which is applied to mechanical equipment, one-way clutches, wrenches, etc., can solve the problems of complex reversing structure and cannot guarantee ratchet strength, etc., and achieve simple reversing structure, simple structure and strong thrust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

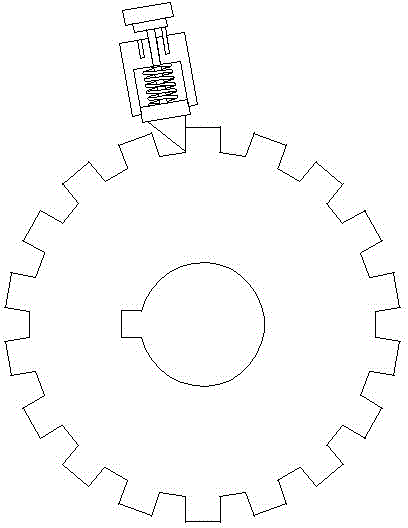

[0026] Embodiment 1 The ratchet mechanism for convenient reversing

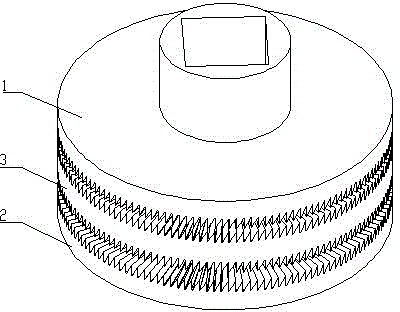

[0027] The convenient reversing ratchet mechanism of the present invention comprises a first ratchet 1 and a second ratchet 2 with ratchets, a one-way braking element 3 is arranged between the first ratchet 1 and the second ratchet 2, and the The one-way brake element 3 can selectively block the ratchet of the first ratchet 1 or the second ratchet 2; the one-way brake element 3 is magnetically attracted and stuck to the first ratchet 1 or the second ratchet 2 ratchet. preferred, such as figure 2 As shown, the one-way braking element 3 is in the shape of a cylinder, and ratchet teeth are arranged on the upper surface of both sides of the cylinder, and the first ratchet 1, the one-way braking element 3 and the second ratchet 2 are arranged coaxially in sequence. The first ratchet 1 and the second ratchet 2 are provided with ratchets on the end faces near the side of the one-way braking element 3. When the t...

Embodiment 2

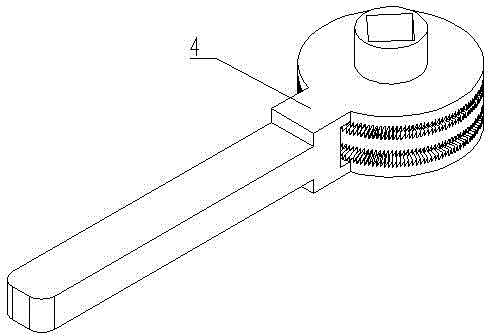

[0029] Embodiment 2 ratchet wrench

[0030] The ratchet wrench, such as image 3 and 4 As shown, a wrench head 4 is included, and a ratchet mechanism is provided in the wrench head 4, and the ratchet mechanism includes a first ratchet 1 and a second ratchet 2 with ratchet teeth, and the first ratchet 1 and the second ratchet 2 A one-way brake element 3 is arranged between them, and the one-way brake element 3 can selectively block the ratchet teeth of the first ratchet 1 or the second ratchet 2; the one-way brake element 3 is attracted by magnetic force And block the ratchet of the first ratchet 1 or the second ratchet 2. Preferably, the one-way brake element 3 is in the shape of a cylinder, and ratchet teeth are arranged on the circumferential surface of both sides of the brake element, and the first ratchet 1, the one-way brake element 3 and the second ratchet 2 are arranged coaxially in sequence, Ratchet teeth are provided on the end faces of the first ratchet 1 and the ...

Embodiment 3

[0033] Embodiment 3 Ratchet screwdriver

[0034] Ratchet screwdriver of the present invention, as Figures 5 to 7 As shown, it includes a handle 6 and a screwdriver rod 7, the handle 6 is provided with a ratchet mechanism; the ratchet mechanism includes a first ratchet 1 and a second ratchet 2 with ratchets, the first ratchet 1 and the second ratchet A one-way braking element 3 is arranged between the ratchets 2, and the one-way braking element 3 can selectively block the ratchet teeth of the first ratchet 1 or the second ratchet 2; The magnetic force attracts and blocks the ratchets of the first ratchet 1 or the second ratchet 2 . Preferably, the one-way braking element 3 is cylindrical and has magnetism, ratchet teeth are arranged on the two side end faces of the one-way braking element 3, and the first ratchet 1, the one-way braking The moving element 3 and the second ratchet 2 are arranged coaxially in turn, and ratchet teeth are arranged on the end faces of the first ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com