Sliding plate reciprocating mechanism

A technology of reciprocating motion mechanism and slide plate, which is applied in the direction of electromechanical devices, mechanical equipment, electric components, etc., can solve the problems of poor stability of reciprocating motion, difficult to change, control, use restrictions, etc., and achieve simple structure, low cost, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

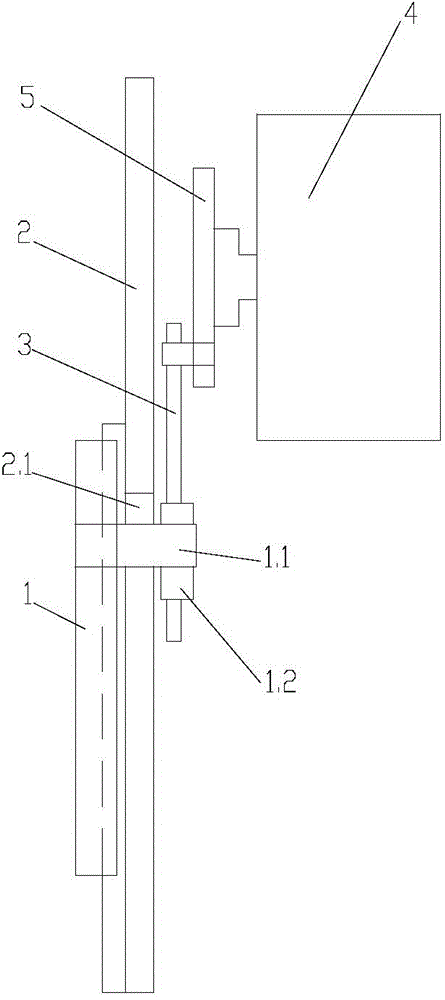

[0012] Such as figure 1 The shown reciprocating motion mechanism of a skateboard comprises a skateboard 1, a skateboard seat 2, a crank 3, and a motor 4. The skateboard 1 and the skateboard seat 2 are slidably connected with a dovetail groove structure, and the motor 4 is arranged at the rear upper end of the skateboard seat 2. 4 The output shaft is provided with a turntable 5, the motor 4 is provided with a reducer, and the crank 3 is arranged on the bottom side of the turntable 5. One end of the crank 3 is movably connected with the turntable 5, and the other end is movably connected with the pin shaft 1.1 provided on the skateboard 1. The pin shaft 1.1 Protrude to the rear side of the skateboard 1, the connection between the pin shaft 1.1 and the crank 3 is provided with a runner 1.2 connected with the crank 3, and the position opposite to the skateboard seat 2 is provided with a through hole 2.1 matching the pin shaft 1.1, and the size of the through hole 2.1 is far Much l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap