Alloy sealing ring

A sealing ring and alloy technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of shrinkage and deformation of sealing rings, affecting pipeline work, and easy aging of rubber rings, and achieves reasonable structure, good corrosion resistance, and excellent performance. The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

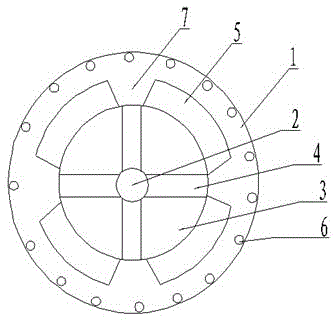

[0020] see figure 1 , the embodiment of the present invention includes:

[0021] The alloy sealing ring, the outermost layer is a fluoroplastic sealing sleeve, the middle part is an intermediate fixed shaft, the intermediate fixed shaft is connected to a copper metal bracket, the copper metal bracket is in the shape of a cross, and the copper metal bracket is To further support the alloy sealing ring, preferably, the copper metal bracket can also be replaced with a cross rib.

[0022] The fluoroplastic sealing sleeve is the main body of the alloy sealing ring. The fluoroplastic sealing sleeve is made of fluoroplastic, which is corrosion resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap