The design structure of inlet side to side of 1500℃ ultra-high temperature angle globe valve

An angle-type globe valve and a technology of designing a structure, which is applied in the field of valve manufacturing, can solve the problems of large heat loss of the medium, no retrieval, and the medium at the outlet of the valve cannot meet the requirements of the test, etc., and achieves the effect of reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

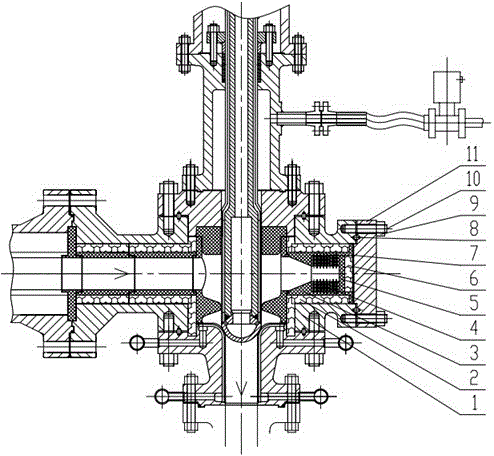

[0025] See figure 1 , a 1500°C ultra-high temperature angle stop valve inlet side-to-side design structure, characterized in that: the main valve body 1 on the side opposite to the inlet end of the angle stop valve is provided with a slag collection tank, the slag collection tank also has The role of the observation window.

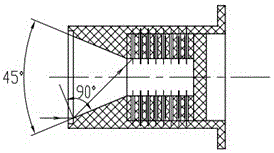

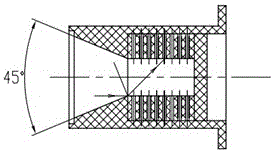

[0026] The slag collecting tank includes a collecting cone ring 3, which is installed at the main valve body 1 on the opposite side of the inlet end of the angle stop valve, and a heat insulating ring 2 is arranged between them; the collecting cone ring The front end of 3 is a cone structure, and the rear end is a column structure, in which the slag collection bucket 4, wear plate 5, heat insulation plate 6, buffer plate 7 are installed in sequence, and then the end cover 11 passes through the seal 8 and the nuts and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com