An LED light source module, an LED light bar, and a direct-lit backlight module

An LED light source and LED light bar technology, applied in the electrical field, can solve the problems of complicated implementation methods, and the thickness of the direct-down module cannot be reduced, and achieve the effects of ultra-thin, increased distance, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

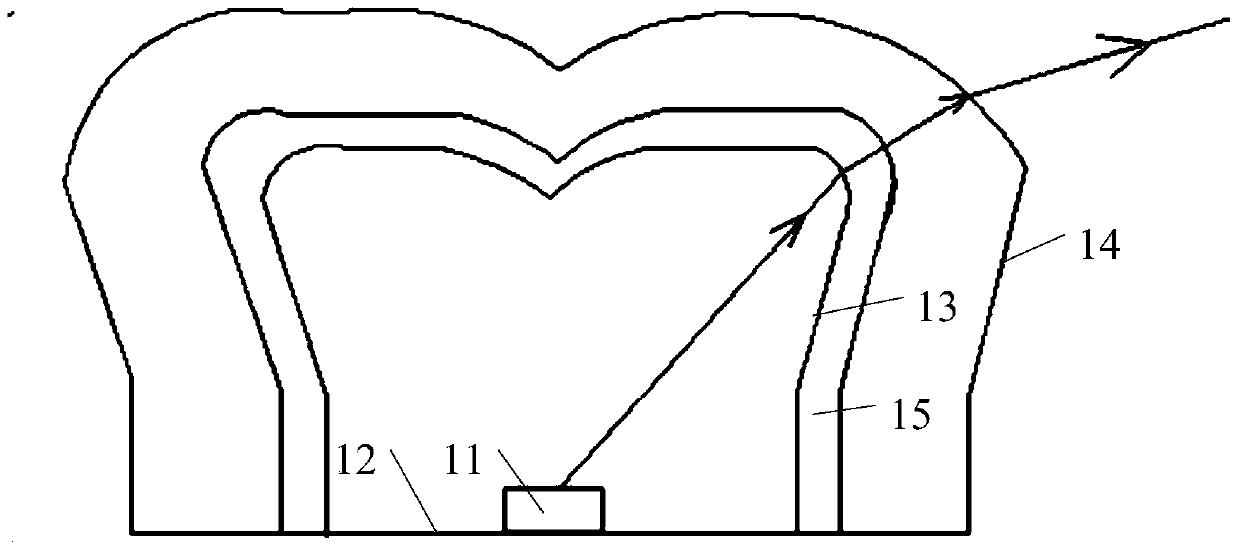

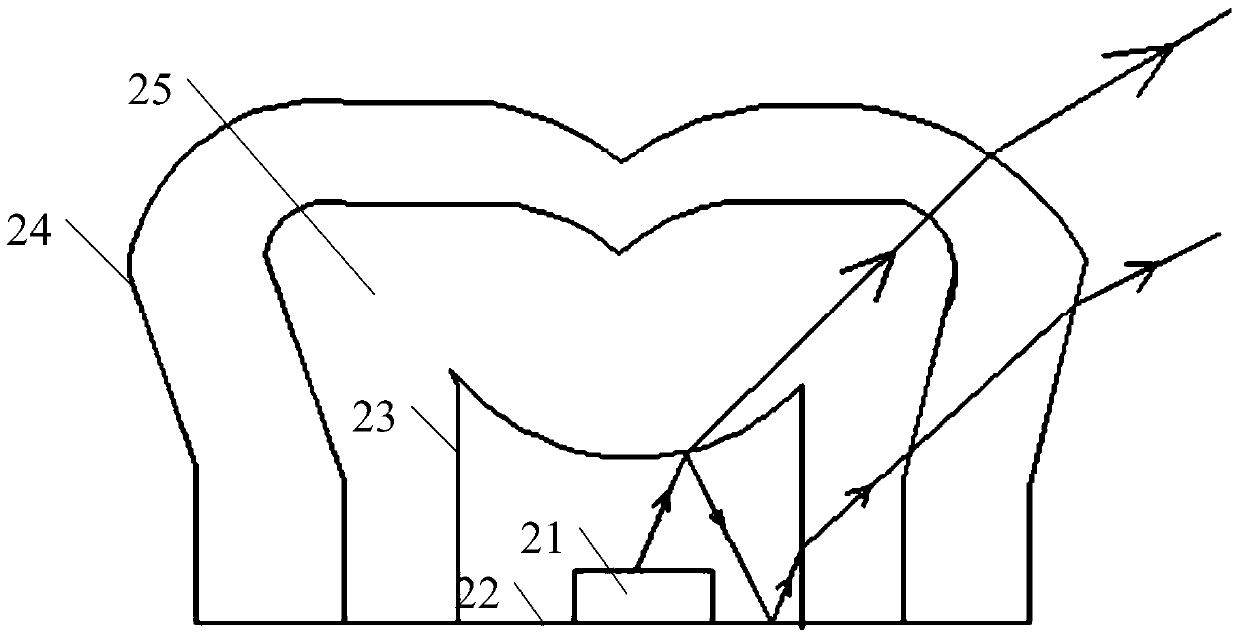

[0026] The embodiment of the present invention provides an LED light source module, which includes an LED light source, a bottom plate for carrying the LED light source, two or more lenses are nested outside the LED light source, and the two Or the center lines of two or more lenses coincide with the center lines of the LED light source to make the emitted light uniform.

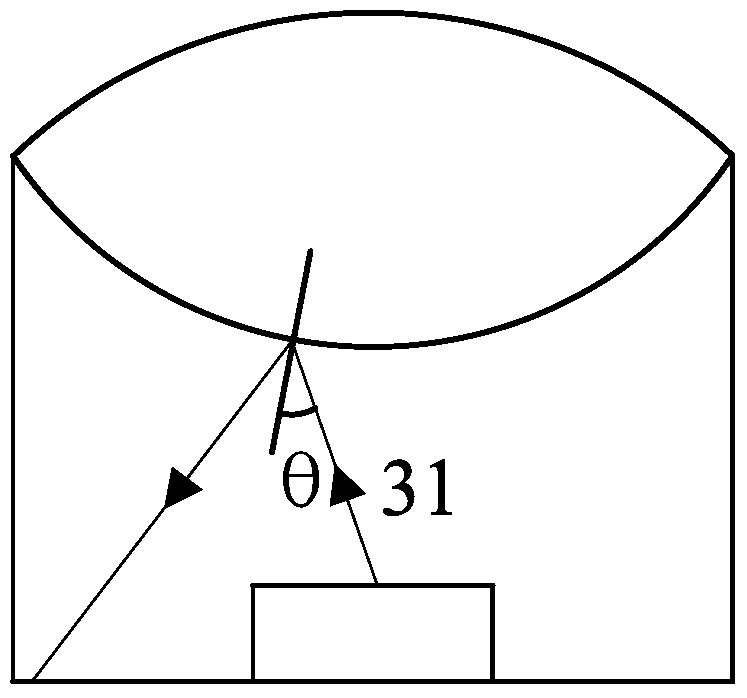

[0027] The design principle of the present invention is: when the light emitted by the LED light source passes through the lens, because the refractive index of the air layer and the lens are different, and the refractive index of the lens in this technical solution is greater than that of the air layer, the light is emitted from the lens to the air. Refraction occurs when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap