A sintering waste heat power generation system and method using a screw expander to drive it

A screw expander, waste heat power generation technology, applied in the direction of machine/engine, waste heat treatment, mechanical equipment, etc., can solve the problems that the steam cannot fully meet the requirements, the power generation efficiency of the steam turbine is not high, and achieve the effect of improving the recycling rate and saving electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

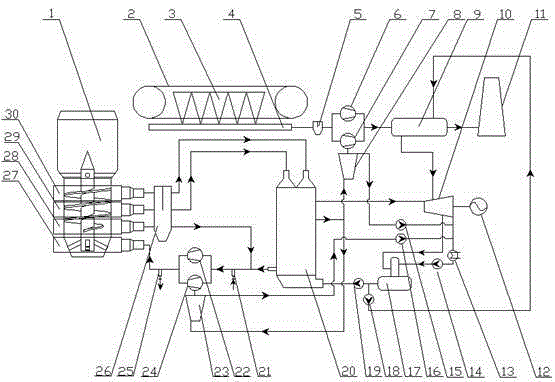

[0013] Such as figure 1 As shown, the screw expander dragged sintering waste heat power generation system includes sinter vertical cooling device 1, sintering machine 2, bellows 3, main flue 4, dust collector 5, first electric fan 6, first fan 7, first Screw expander 8, heat pipe waste heat boiler 9, steam supplement condensing steam turbine 10, chimney 11, generator 12, condenser 13, first water pump 14, second water pump 15, third water pump 16, deaerator 17, first water pump Four water pumps 18, fifth water pump 19, double inlet and double pressure waste heat boiler 20, cold air inlet valve 21, second electric fan 22, second screw expander 23, second fan 24, release valve 25, dust collector 26, The air inlet chamber 27 of the sinter vertical cooling device, the low temperature air outlet chamber 28 of the sinter vertical cooling device, the medium temperature air outlet chamber 29 of the sinter vertical cooling device, and the high temperature air outlet chamber 30 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com