Percussion safety structure of firearm

A technology for firing insurance and firearms, applied in the field of firearms, can solve the problems of complex structure of insurance institutions, unreliable insurance effects, etc., and achieve the effects of wide application and promotion value, reliable insurance, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

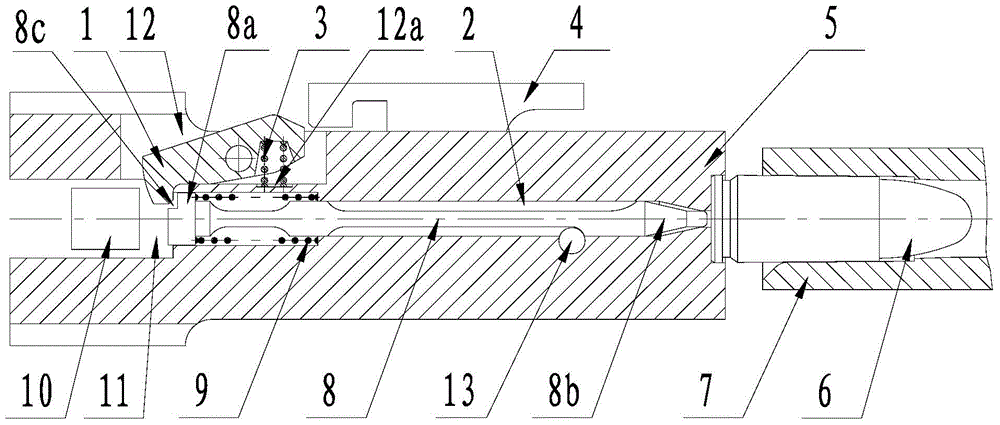

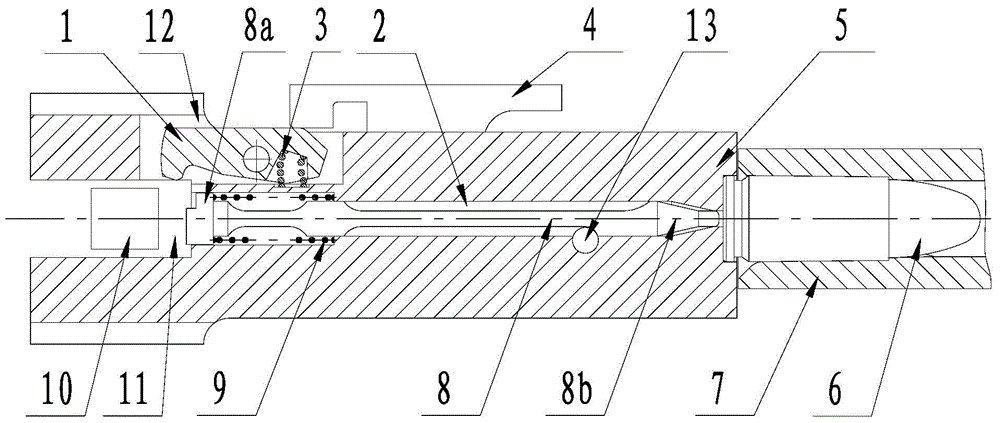

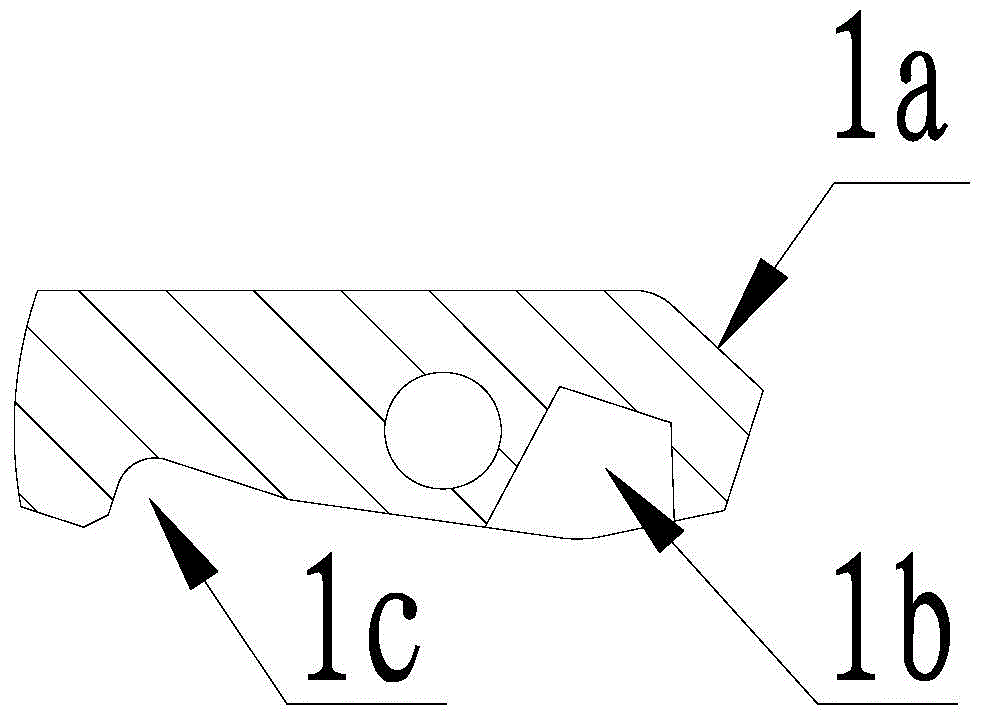

[0022] see figure 1 , figure 2 , is a kind of embodiment of the percussion safety structure of firearms, comprises gun body 5, firing pin 8, ejection stand 4, and the front of described gun body 5 corresponds to gun barrel 7, and bullet 6 is installed in the gun barrel 7, and bullet 6, Gun barrel 7, firing pin 8 coaxial center lines. Described shell ejection is quite 4 and is installed on the casing (not shown in the figure), and gun body 5 can sit back and advance longitudinally relative to the casing along itself. The firing pin mounting hole 2 and the hammer passing hole 11 are arranged in the gun body 5 in sequence from front to back, the firing pin 8 is installed in the firing pin mounting hole 2, and the rear end of the firing pin 8 is connected to the hammer passing hole. 11 relative.

[0023] In this embodiment, the front end of the firing pin 8 is a shuttle-shaped head 8b, and the shuttle-shaped head 8b can protrude from the front end outlet of the firing pin moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com