On-line monitoring method of resistance spot welding quality

A technology of resistance spot welding and dynamic resistance curve, which is applied to measuring devices, instruments, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

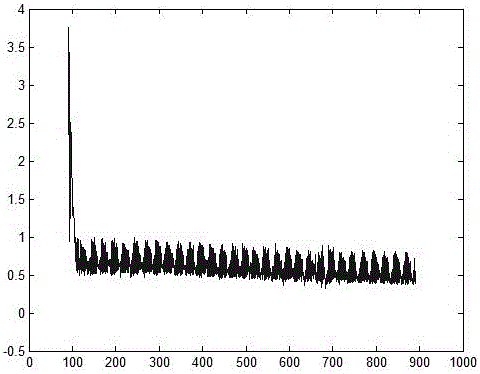

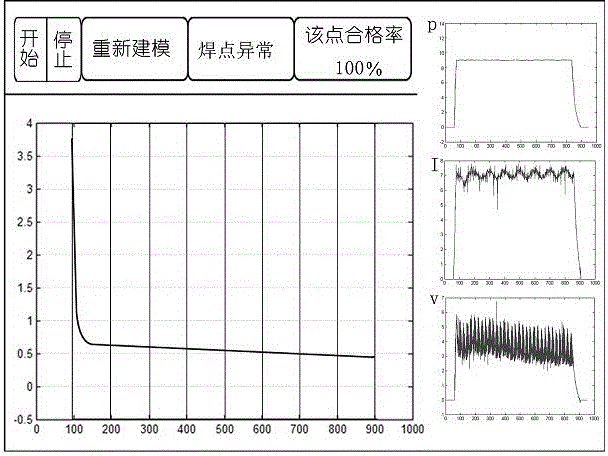

[0101] This embodiment takes SUS301-HT, 1+1mm stainless steel plate single-current pulse welding as an example, the spot welding process is: welding current 7KA, electrode pressure 9KN, welding energization time 8cyc (per cycle is 20ms).

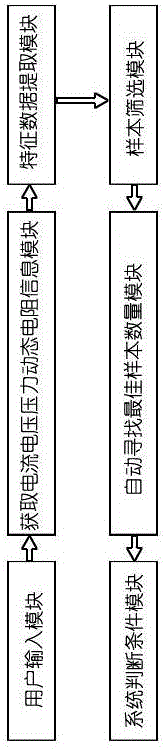

[0102] see figure 1 As shown, it is the flow chart of data acquisition and data processing in the present invention. First start the program, and set the spot welding welding parameters according to the actual welding process specification (including: welding current I is 7KA and its power-on time t is 8cyc, electrode pressure P is 9KN) and its allowable range (the allowable upper and lower ranges are respectively 90% and 110% of the set welding parameters); in addition, set other relevant spot welding process information, such as material type SUS301-HT stainless steel, plate thickness 1+1mm, etc. After the setting is completed, Start the welding equipment for data collection.

[0103] During signal collection, the welding signal is automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com