Large-flow sampling device for industrial flue gas particulate matters

A technology of industrial flue gas and sampling devices, applied in the direction of sampling devices, etc., can solve the problems of limited flow, low concentration, increased labor intensity and cycle of environmental monitoring, and achieve the effect of shortening the sampling cycle and improving sampling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

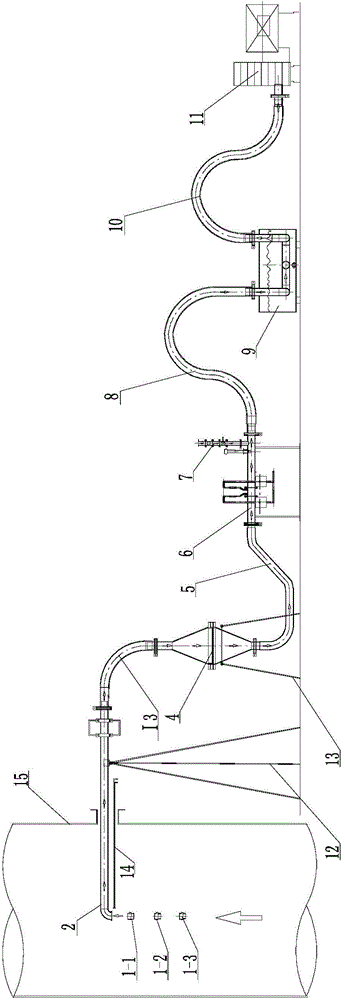

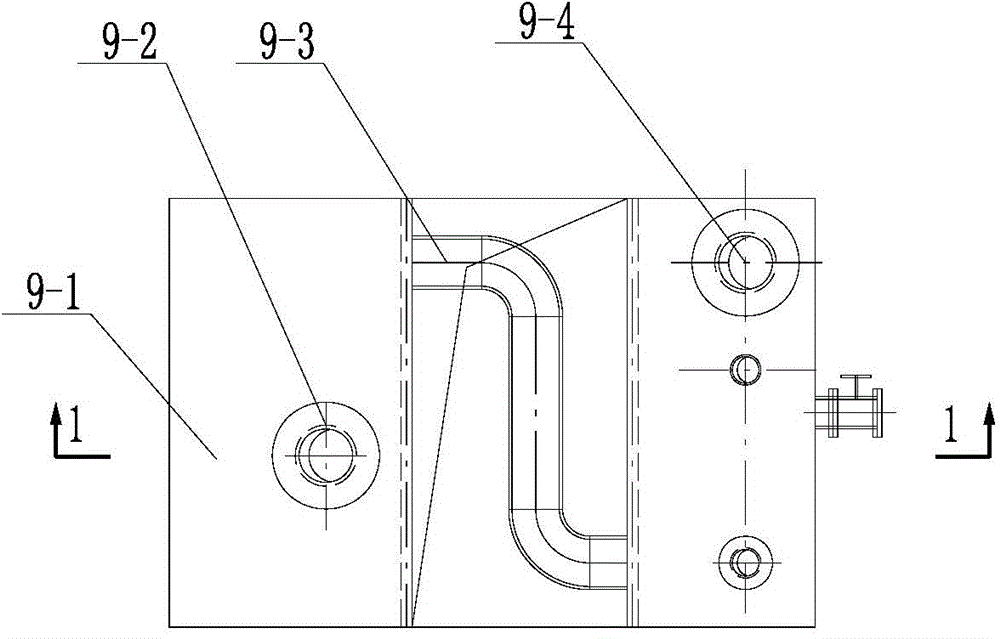

[0020] See Figure 1 to Figure 8 , a large-flow industrial flue gas particulate matter sampling device, including a sampling gun 2, a filtering device 4, a flow metering device 6, a dilution cooling device 7, a water cooling device 9 and a vortex air pump 11 connected in sequence through pipelines. 2 is provided with a bracket I12 fixedly connected to it, and the filter device 4 is installed on the bracket II13.

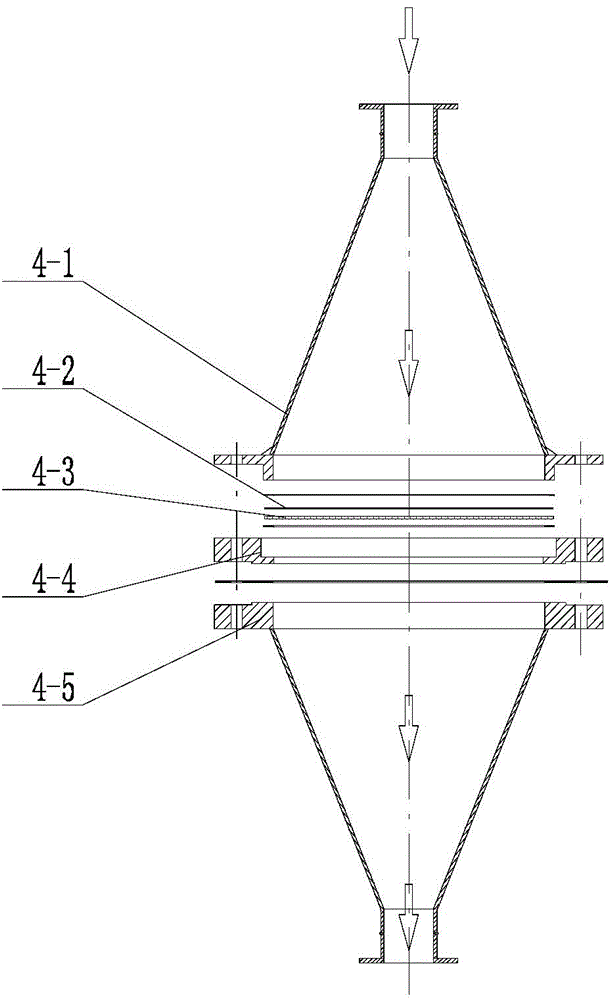

[0021] The filter device 4 includes an upper cone 4-1 and a lower cone 4-5 symmetrically arranged up and down, the diameter of the upper cone 4-1 gradually increases from top to bottom, and the upper cone and the lower cone 4-5 gradually increase in diameter. A support ring 4-4 is sandwiched between the lower cones, and a groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com