Vehicle-mounted quick checking system

A rapid inspection, vehicle-mounted technology, applied in general control systems, control/regulation systems, motor vehicles, etc., to achieve the effect of rapid inspection process, realization of motorization, and realization of inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

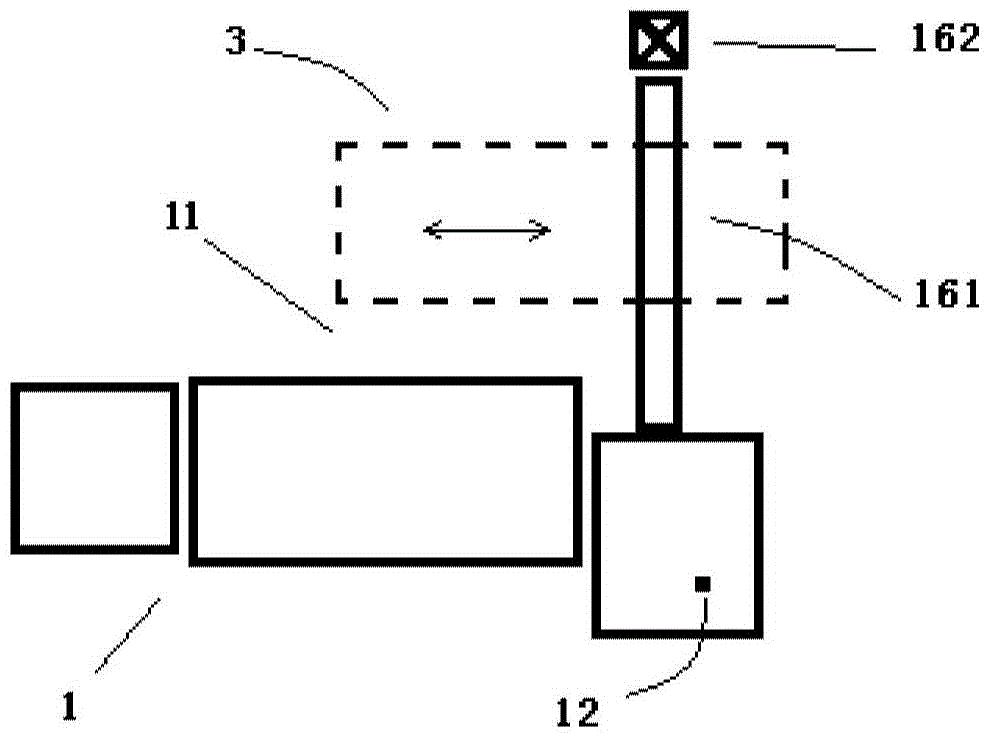

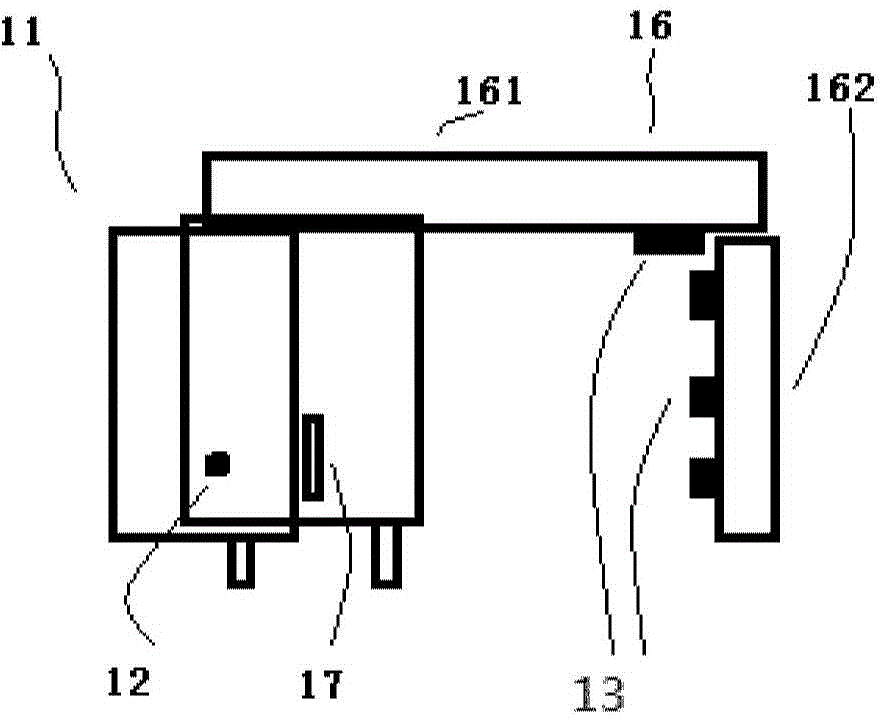

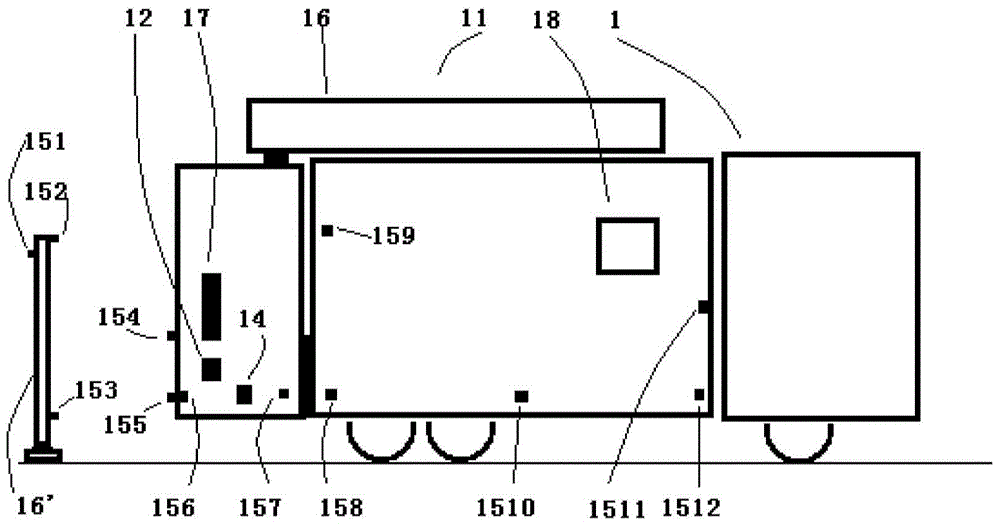

[0019] Refer below Figure 1-4 A vehicle-mounted quick inspection system 11 according to an embodiment of the present invention is described, which is installed on a vehicle 1 .

[0020] The vehicle-mounted rapid inspection system includes an X-ray source 12 , such as an adjustable emission dose X-ray accelerator 12 , arranged on the vehicle 1 on which the vehicle-mounted rapid inspection system 11 is installed. Preferably, the X-ray accelerator 12 is installed at the rear of the vehicle 1 of the vehicle-mounted rapid inspection system. It should be understood that the X-ray accelerator 12 can be installed in other parts of the vehicle 1 of the vehicle-mounted rapid inspection system. The X-ray accelerator 12 can emit high-dose X-rays when inspecting inspection objects such as containers / goods of container vehicles. However, when the front part or designated part of the container vehicle, that is, the manned part, passes near the X-ray accelerator 12, the X-ray accelerator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com