Rapidly-assembled storage battery system and electric vehicle with same

A storage battery system and storage battery technology, applied to battery components, circuits, electrical components, etc., can solve problems such as battery leakage, fire risk, etc., and achieve the effects of high installation efficiency, convenient installation, and stable electrical connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

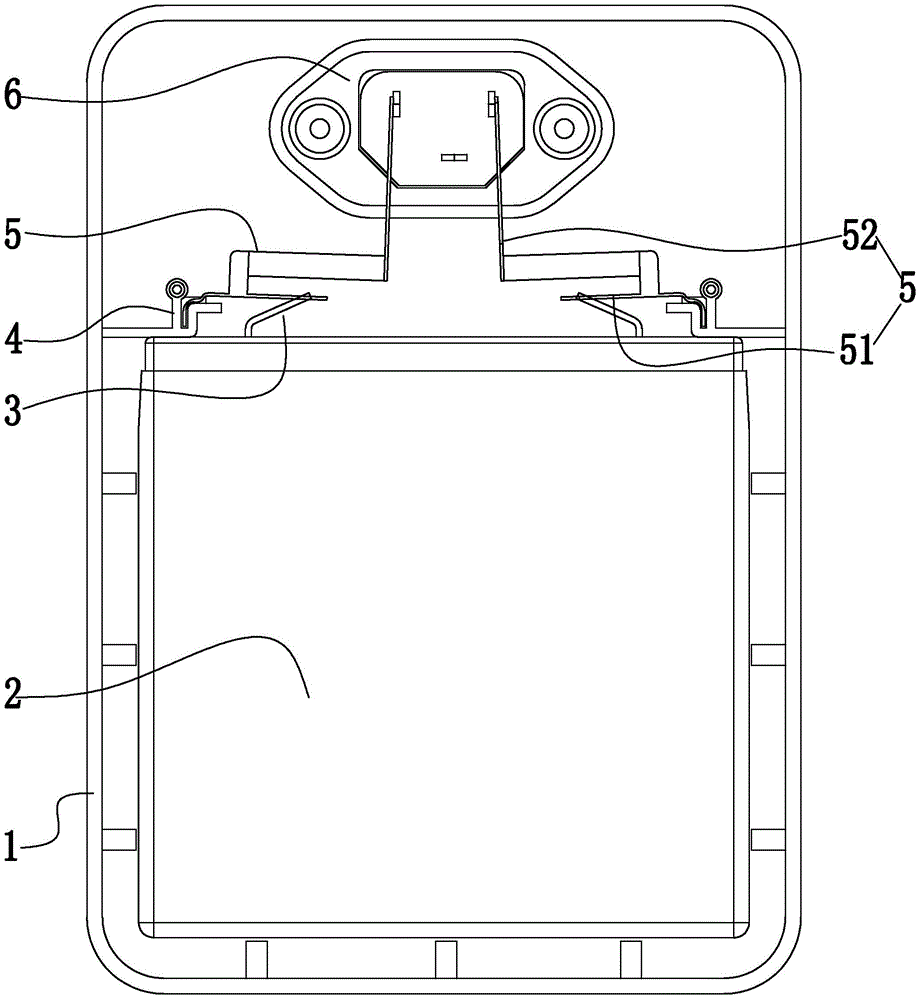

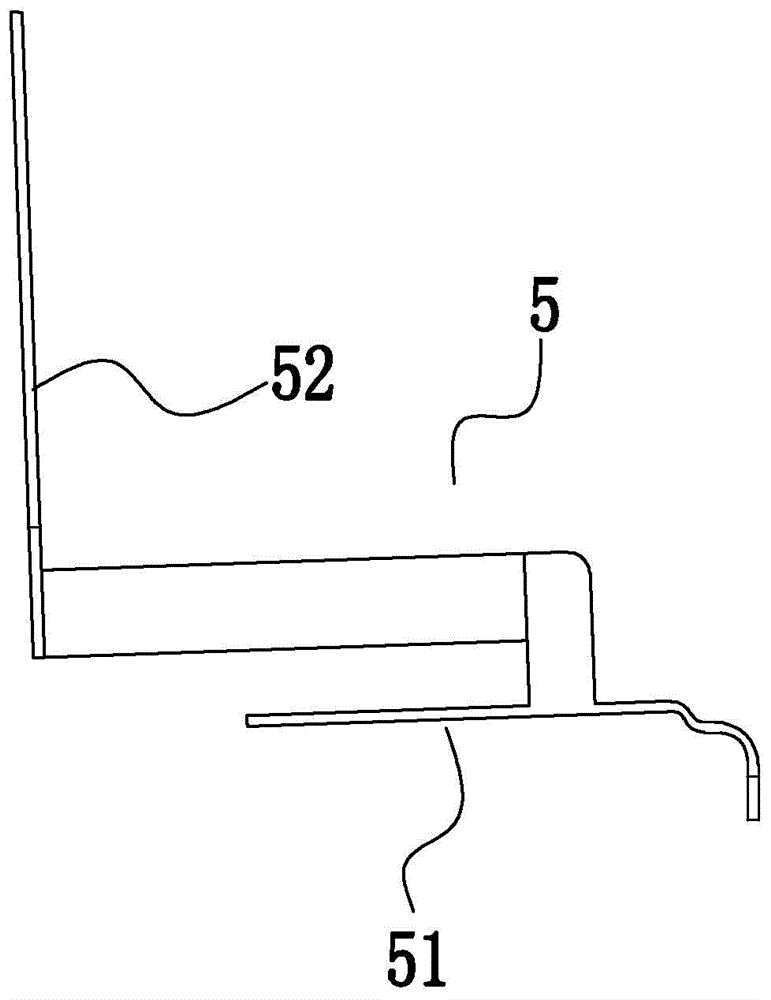

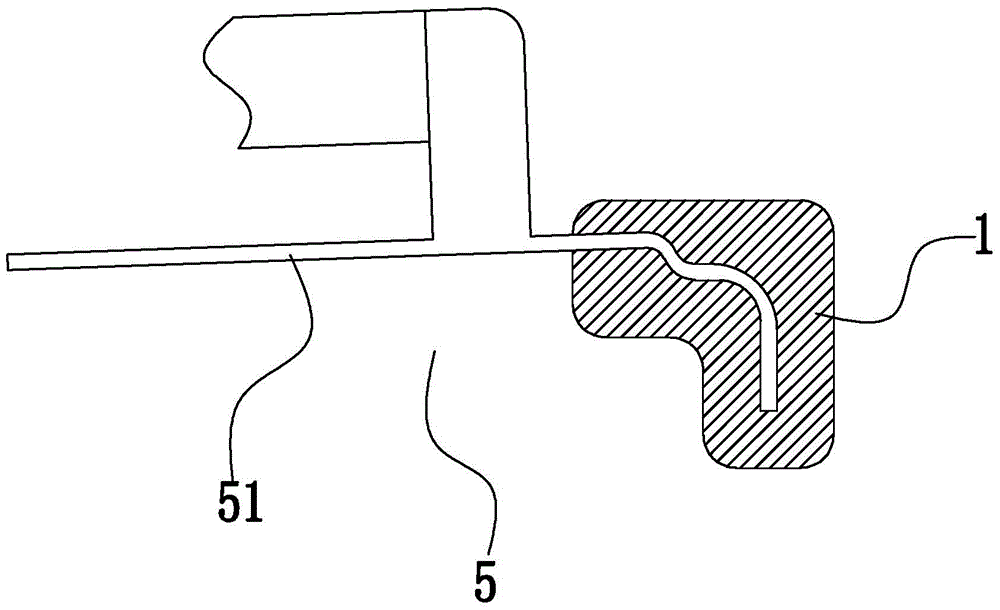

[0060] Embodiment 1: as figure 1 As shown, a quick-install battery system includes a battery box 1 , a power socket 6 and a battery 2 arranged on the battery box. The battery consists of one battery cell. The inner wall of the battery box is provided with a first conductive member 5 for connecting the power socket and the battery terminal of the storage battery installed in the battery box. The first conductive member is electrically connected to the power socket. The battery box is provided with a battery slot for installing a storage battery. The first conductive member includes a first lug for electrical connection with a battery terminal of the storage battery and a first electrical connection member 52 for connecting the first lug 51 with the power socket. There are two first conductive parts, one of which is connected to the positive battery terminal and the power socket, and the other first conductive part is connected to the secondary battery terminal and the power ...

Embodiment 2

[0077] Embodiment 2: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0078] Such as Figure 4 , Figure 5 As shown, the storage battery 2 of this embodiment is a battery pack. This storage battery includes four battery cells 2a, 2b, 2c, and 2d. The battery box is provided with four single cell slots for installing single battery cells. The battery cells are sequentially connected in series through the second conductive member 7 arranged on the inner wall of the battery box. After each single battery is installed in the battery box (that is, the single battery is put into the battery box with the battery terminal facing the second conductive member), specifically, when each single battery is installed in the corresponding battery box When using the battery slot, the battery cells are sequentially connected in series through the second conductive member, and the battery cells connected in series are electrically connecte...

Embodiment 3

[0101] Embodiment 3: This embodiment provides an electric vehicle, which includes a quick-install battery system described in any one of Embodiments 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com