Connector plug and manufacturing and assembling method thereof

A connector plug and assembly method technology, which is applied to the assembly/disassembly and connection of components and contacts of the connection device, and can solve the problems of unstable signal transmission, unstable assembly structure of the insulating seat, and mutual interference of signals, etc. problems, to achieve good contact conduction, easy molding and manufacturing, and stable signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

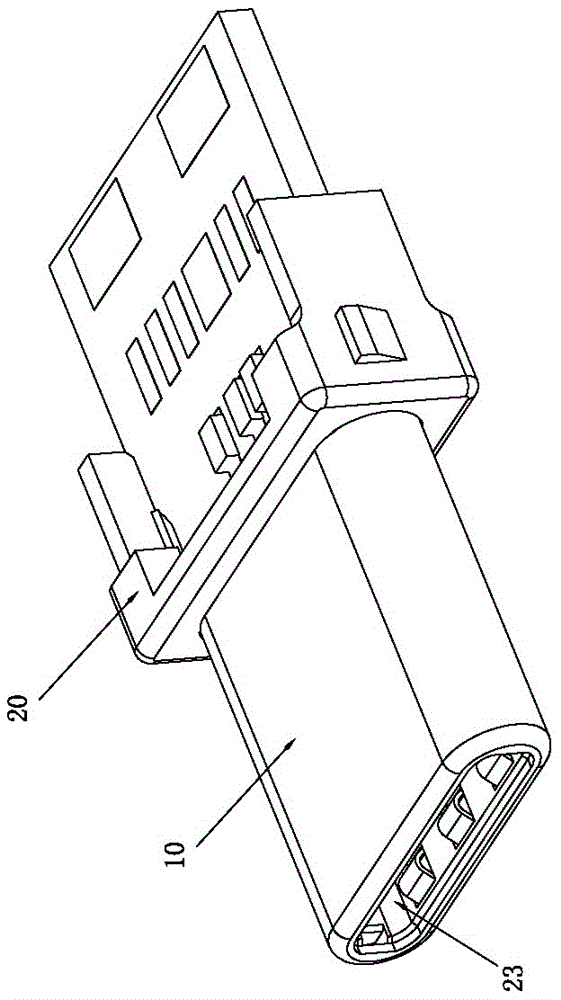

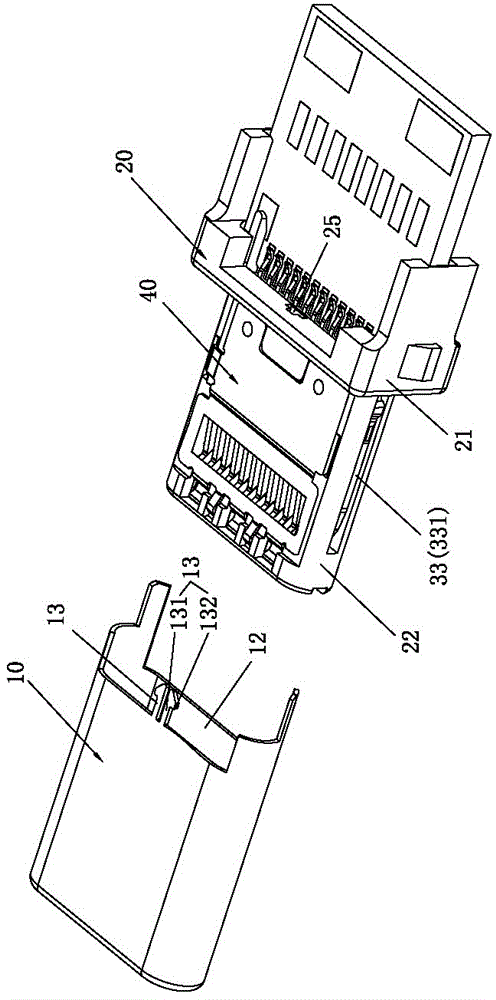

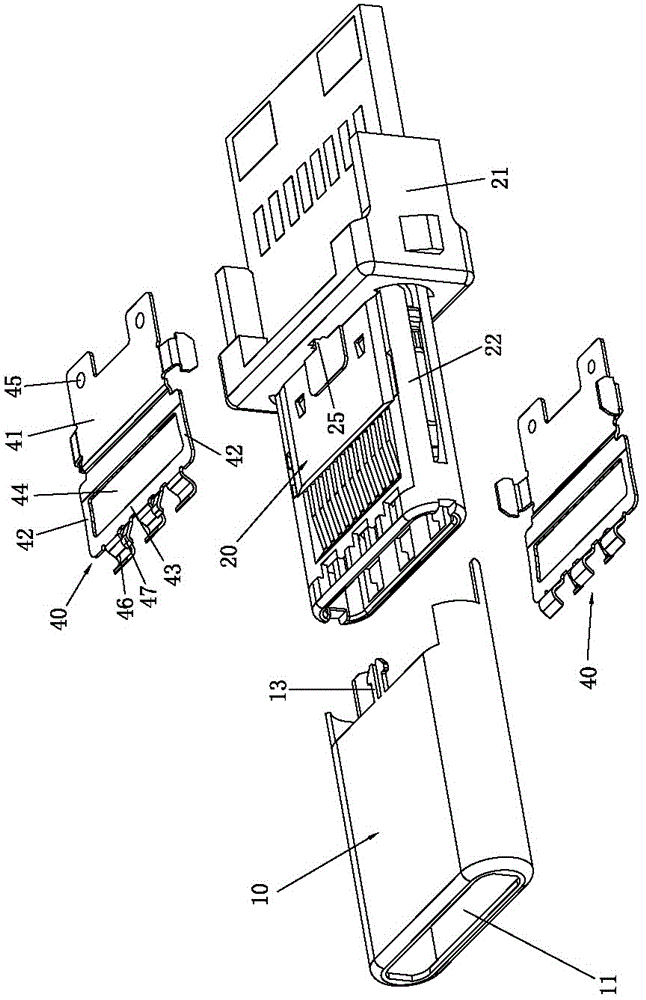

[0058] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention. The connector plug includes a shielding shell 10 , an insulating seat body 20 , a terminal module 30 and two baffles 40 .

[0059] Such as Figure 2 to Figure 5 As shown, the insulating seat body 20 includes a base 21 and a tongue 22 connected to the front end of the base 21. The front end of the tongue 22 is concavely provided with a slot 23 passing through the rear end of the base 21. The tongue 22 A plurality of through holes 221 penetrating through the slot 23 are opened on the upper and lower surfaces of the upper and lower surfaces respectively, and spacer arms 222 are formed between adjacent through holes 221, and the through holes 221 are provided one by one corresponding to each terminal.

[0060] Such as Figure 4 and Figure 5 As shown, the terminal module 30 includes an upper terminal module 31, a lower terminal module 32 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com