Generator support with adjustable height

A generator and height technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem of the height of the bracket is not adjustable, and achieve the effect of stable structure, good heat dissipation performance, and convenient work and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

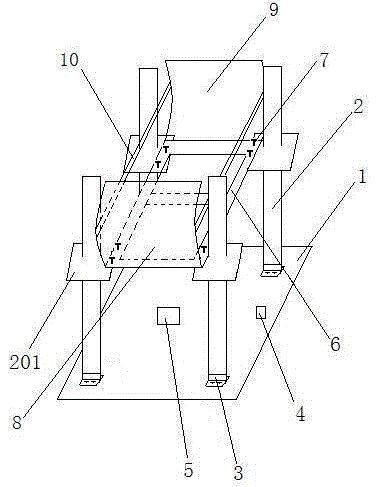

[0012] This embodiment provides such as figure 1 The height-adjustable generator bracket shown includes a support base plate 1, four support legs and a support frame. The support frame is connected to the support base plate 1 through four support legs. The support base plate 1 is provided with four servo motors 3, a power supply 5 and the ascending or descending switch 4, the servo motor 3 is fixed on the support base plate 1 through the screw 7, the servo motor 3 is connected with the power supply 5 through the ascending or descending switch 4, the supporting leg is a ball screw 2, and each servo motor 3 is connected through a joint The shaft device is connected with a ball screw 2, and the four corners of the support frame are passed through screws 7 and nuts 201 of the ball screw 2 arranged on each corner.

[0013] Turn on the up switch or down switch 4 according to the lifting requirements, turn on the power supply 5, the servo motor 3 rotates forward or reverse, and drive...

Embodiment 2

[0015] On the basis of Embodiment 1, the support frame provided in this embodiment includes: a hollow bottom plate 8, two front and rear arc-shaped baffles 9 and left and right fences 10, the front and rear two arc-shaped baffles 9 are connected to the hollow bottom plate 8, and the left and right The fence 10 is connected with the front and rear two curved baffles 9 .

[0016] The front and rear two arc-shaped baffles 9 and the left and right fences 10 ensure that the generator will not fall due to vibration during operation, and the hollow bottom plate 8 is more conducive to the heat dissipation of the generator.

Embodiment 3

[0018] This embodiment is basically the same as Embodiment 1 and Embodiment 2. The difference is that the hollow base plate 8 in this embodiment is hollow, and a damping spring is arranged inside it. The impact of medium vibration on the bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com