Control device for automatic transmission in vehicle

A technology for automatic transmissions and control devices, applied in transmissions, engine control, fluid transmissions, etc., can solve problems such as inability to absorb shocks and torque fluctuations, and achieve the effects of preventing sharp rise, simple control, and preventing speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

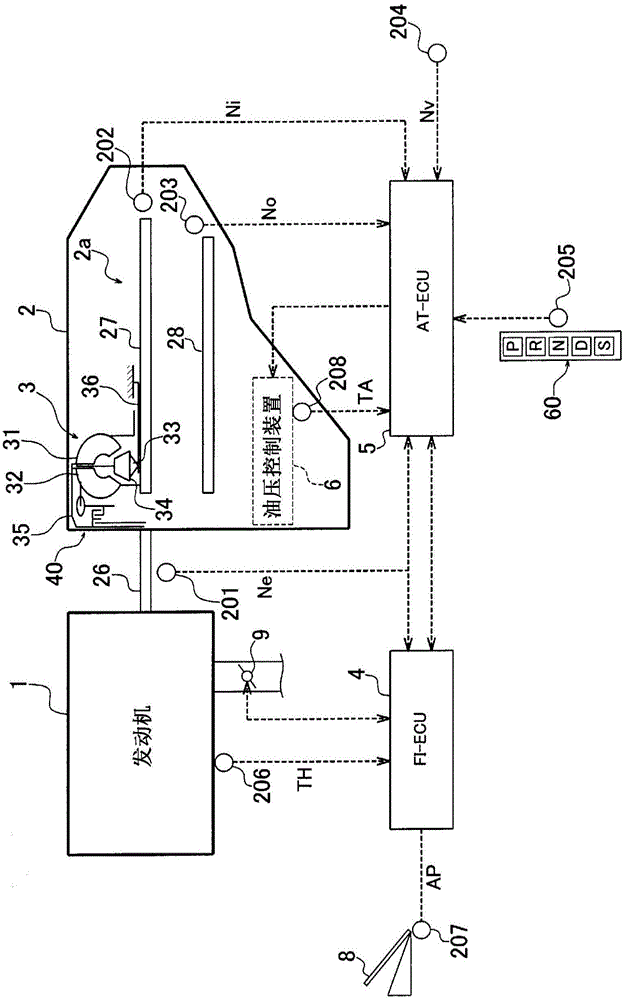

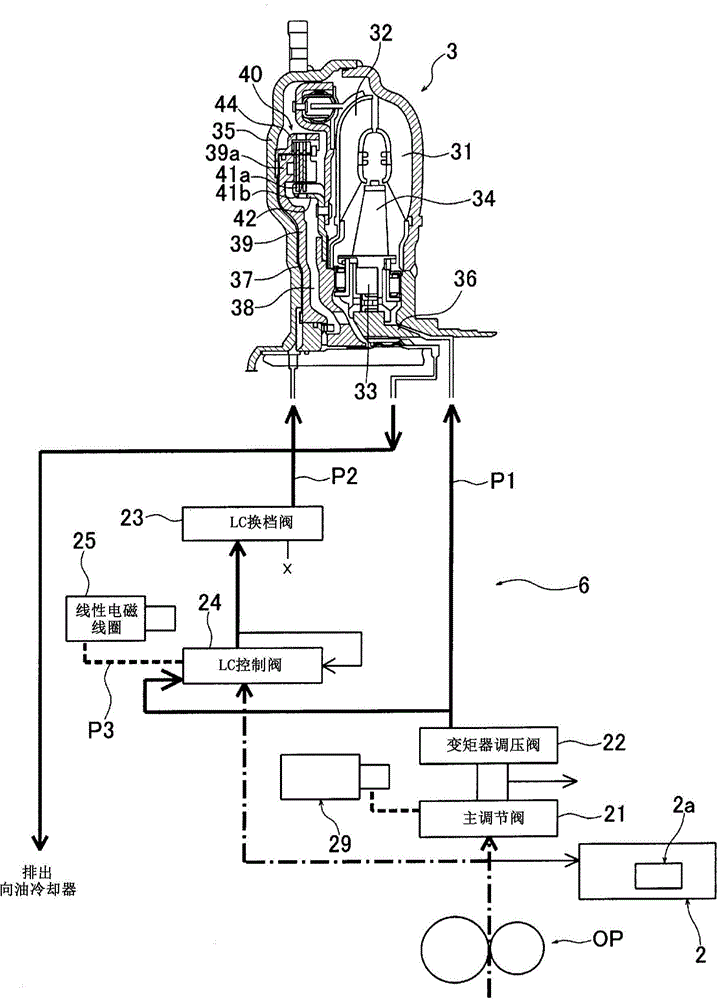

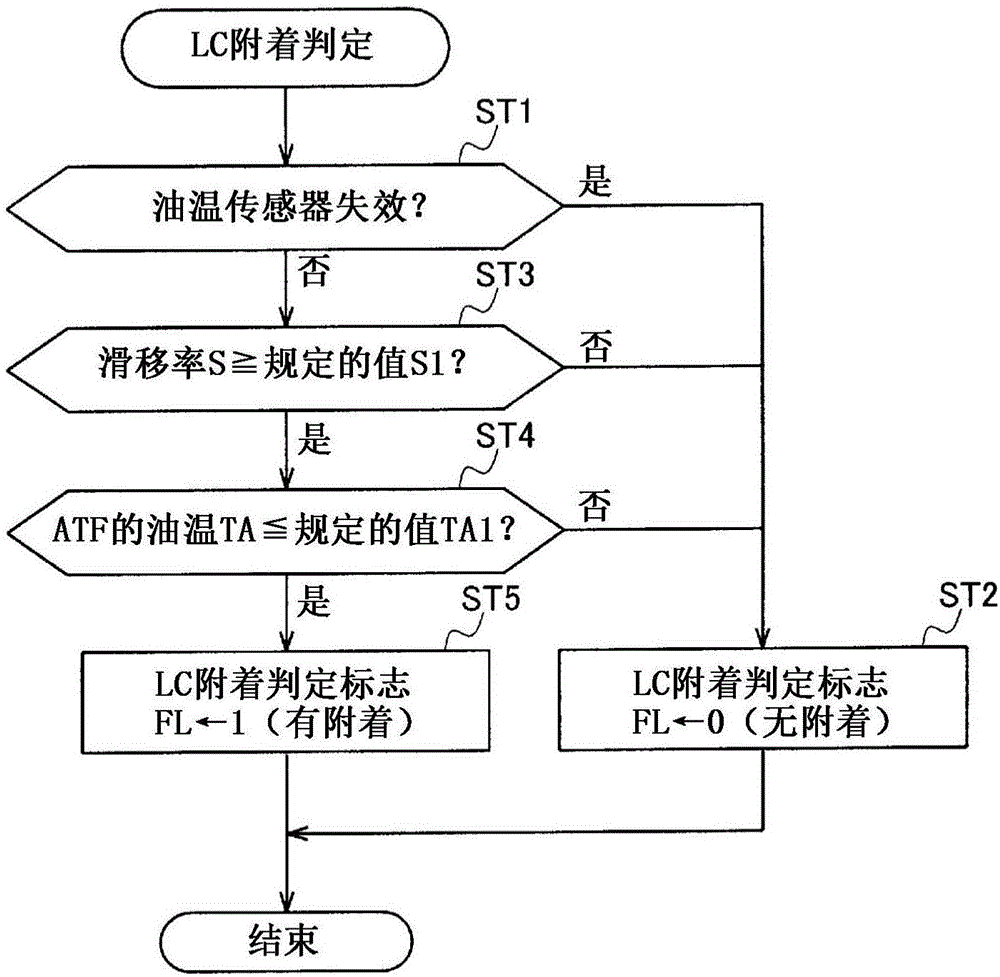

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic diagram of a drive system of a vehicle provided with a control device for an automatic transmission according to an embodiment of the present invention. also, figure 2 It is a diagram showing a torque converter 3 and a hydraulic control device (hydraulic circuit) 6 which will be described later. Such as figure 1 As shown, the vehicle of this embodiment has an engine 1 and an automatic transmission 2 coupled to the engine 1 via a fluid torque converter 3 . The automatic transmission 2 has a shifted type transmission mechanism 2 a capable of setting multiple gears (for example, 6 forward speeds / 1st reverse speed) with different gear ratios. In addition, the vehicle has: FI-ECU 4 that controls engine 1; AT-ECU (control unit) 5 that controls automatic transmission 2 including torque converter 3; rotation drive of the lock-up clutch 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com