Mixed multistage dust collector

A dust collector and housing technology, applied in the mechanical field, can solve the problems of increasing the workload of the dehydration and defogging plate, reducing the stability of the dust collector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

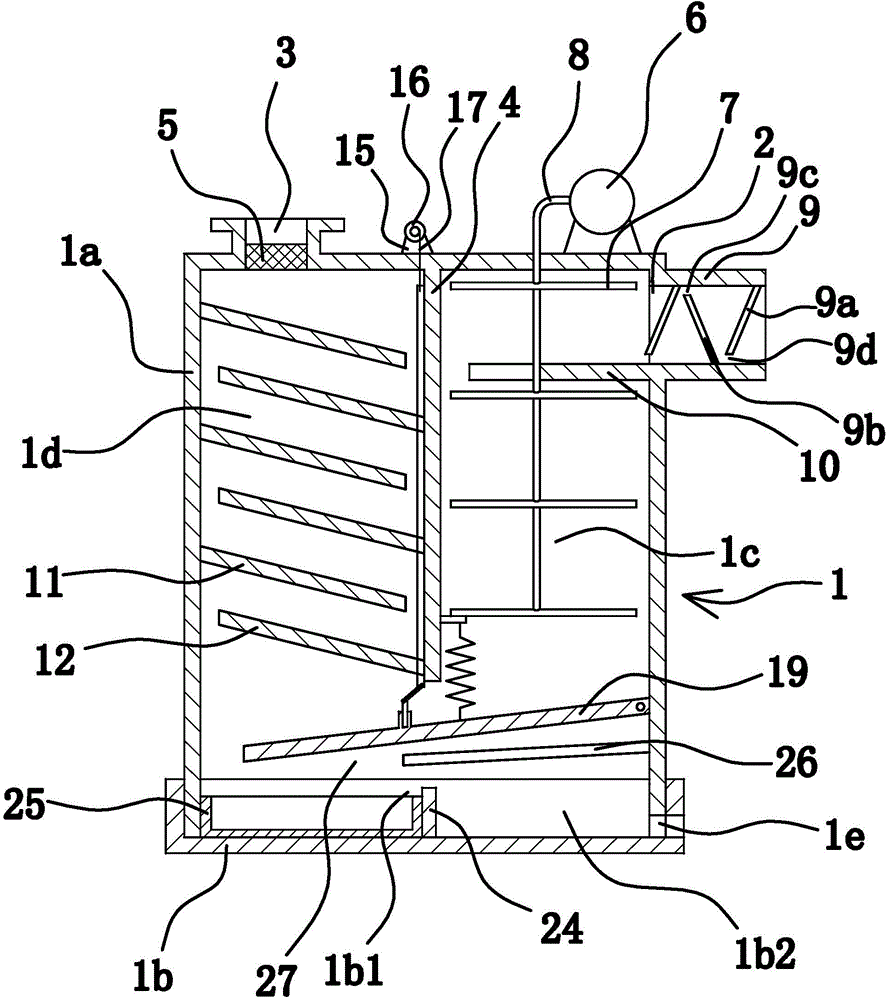

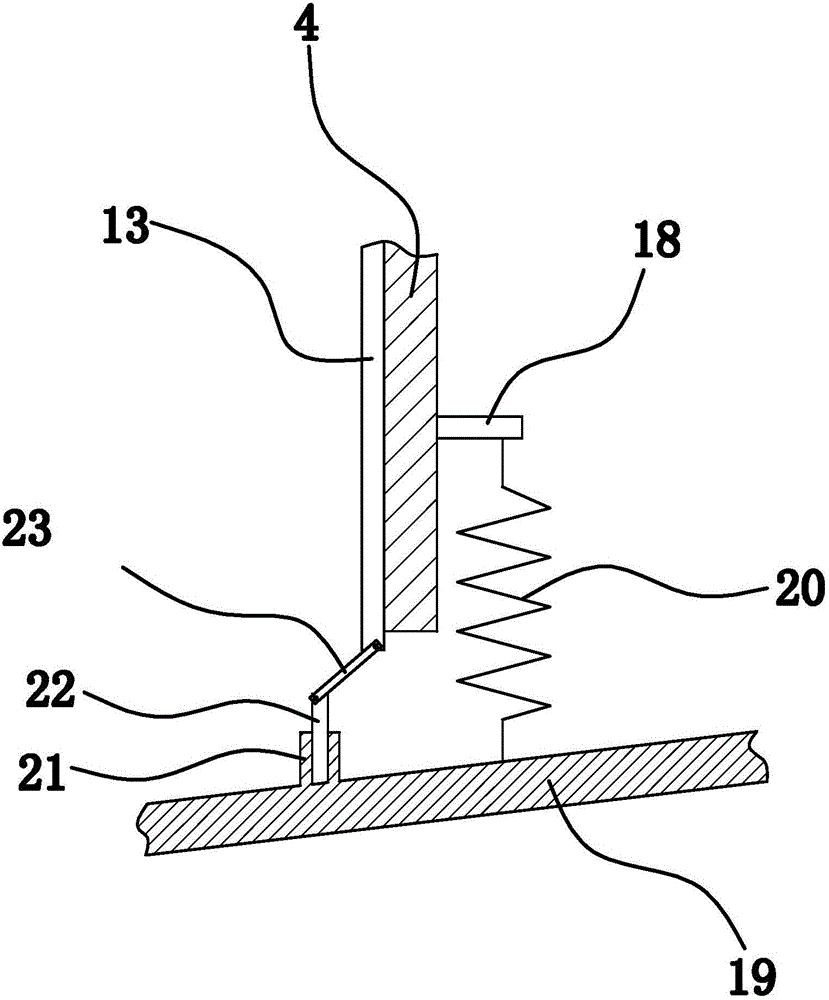

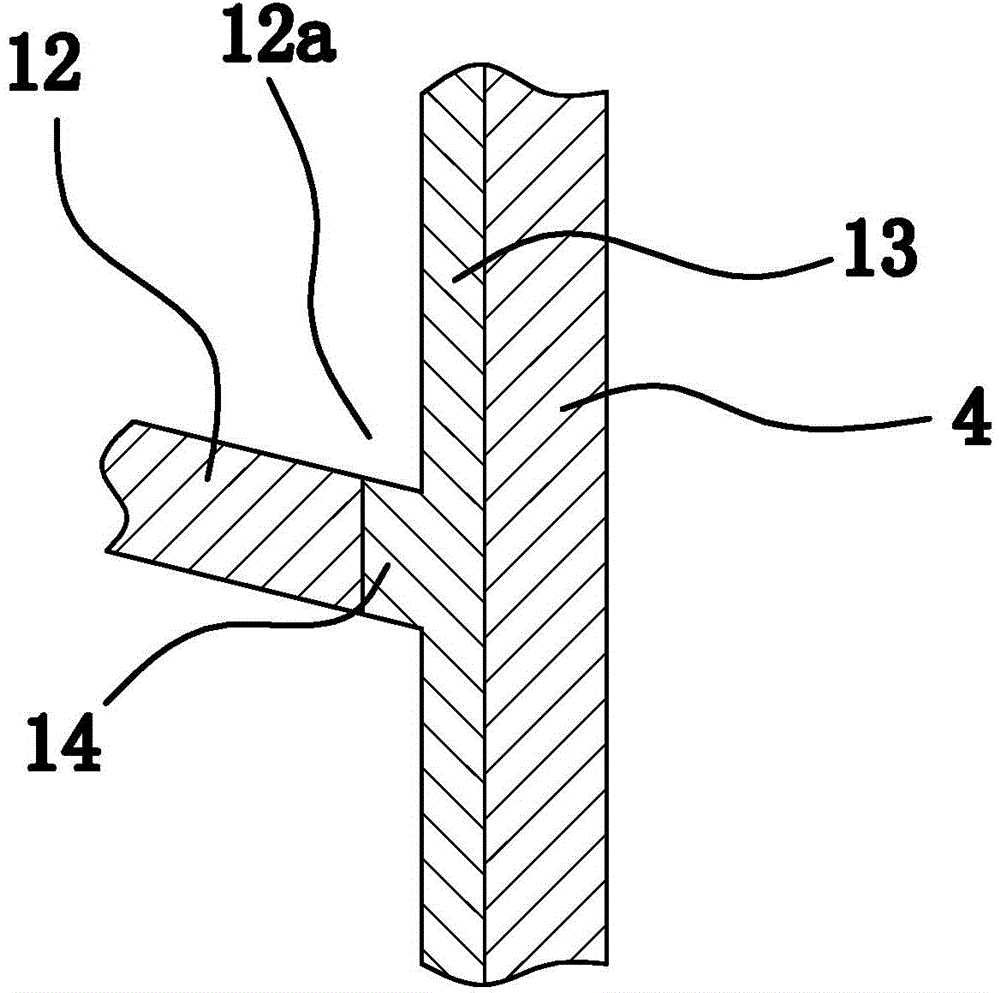

[0072] like figure 1 As shown, the hybrid multi-stage dust collector includes a housing 1 with a cavity inside. In this embodiment, the housing 1 is composed of upper and lower parts, namely: an upper housing 1a and a lower housing connected to the lower part of the upper housing 1a. Housing 1b.

[0073] The housing 1 has an inlet 2 and an outlet 3 communicating with it. The dusty air enters the housing 1 through the inlet 2, and the purified air is discharged from the outlet 3 after filtering.

[0074] A partition 4 is vertically provided in the housing 1, and the partition 4 divides the interior of the housing 1 into two adjacent cavities on the left and right: cavity one 1c and cavity two 1d. In this embodiment, both cavity one 1c and cavity two 1d are located in the upper casing 1 .

[0075] The lower parts of cavity one 1c and cavity two 1d are in communication. In this embodiment, the connection between the above two cavities is located in the lower casing 1b.

[0076...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com