Broaching turbine disc tongue-and-groove full-profile tooth type finishing broach and grinding method thereof

A technology of turbine disk and precision broaching, which is applied in the direction of broaching tools, broaching machines, metal processing equipment, etc., and can solve the problem of not being able to ensure the smooth transfer and correctness of the profile of the full-shaped three-sided edge broach, and the inability to meet the requirements of tooth profile broaching. Knife design requirements and tenon and groove broaching requirements have achieved far-reaching economic and military significance, improved service life, and reduced failure rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

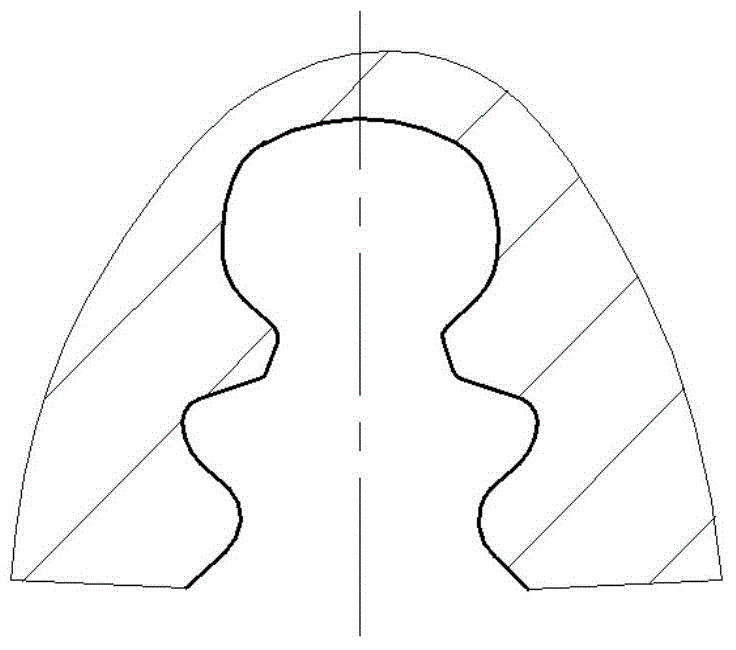

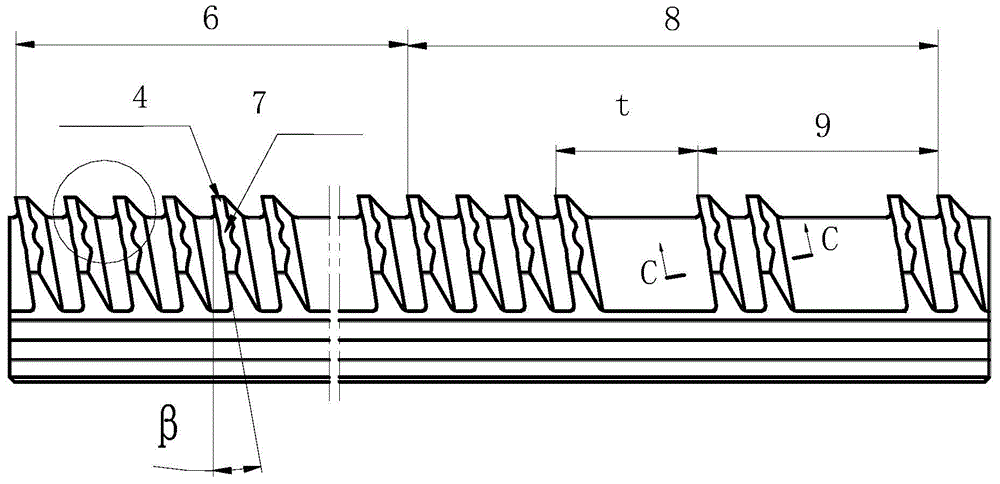

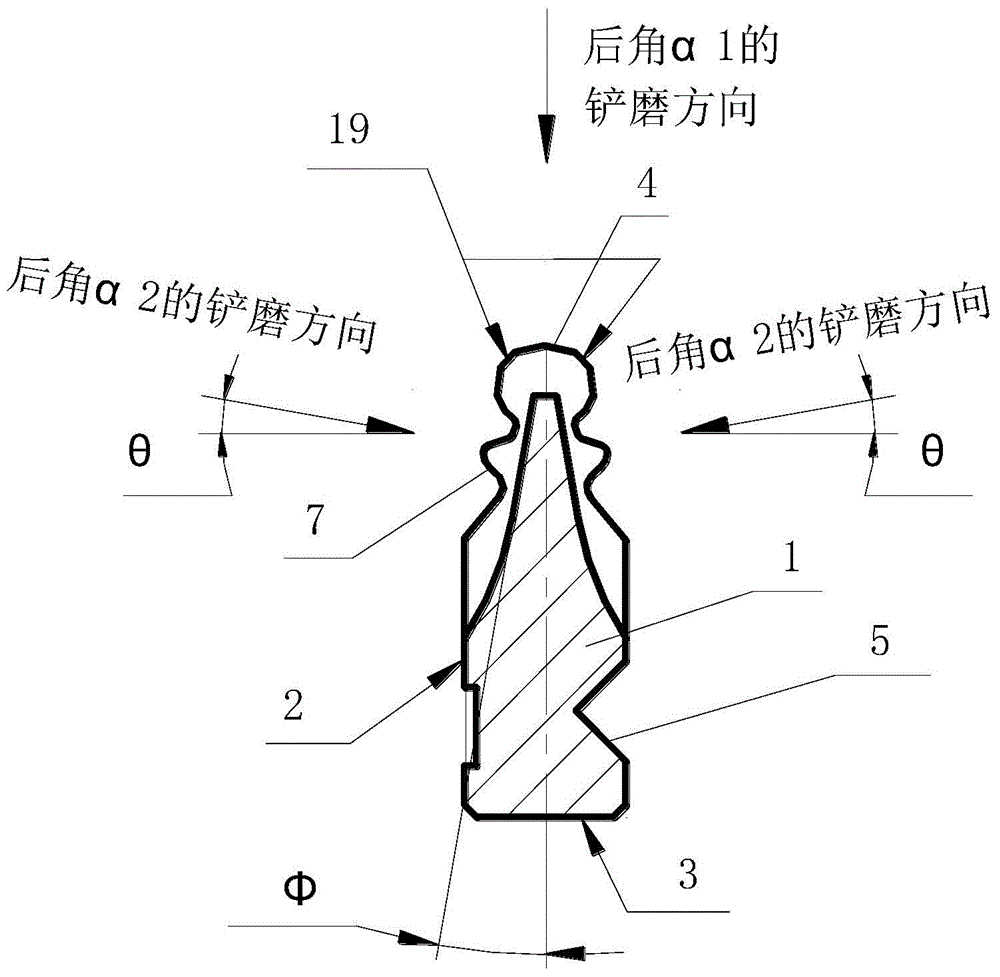

[0042] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a full-profile tooth-type finishing broach for broaching the mortise and groove of a turbine disk, including a cutter body 1 and cutting teeth 6, one side of the cutter body 1 is a side base surface 2, and the other side is provided with There is a V-shaped groove 5 for pressing the broach, the central bisector of the V-shaped groove 5 is parallel to the bottom surface of the cutter body, and the bottom surface of the cutter body is the bottom base surface 3; the cutting teeth 6 include a top cutter arranged on the top surface of the cutter body 1 Teeth 4, and the side cutter teeth 7 symmetrically arranged on both sides of the cutter body 1, the rake faces of the top cutter teeth 4 and the side cutter teeth 7 on both sides are lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com