Sucking rod mechanism capable of sucking acoustic gauze of mobile phone

A technology of rod mechanism and mesh, which is applied in the field of suction mechanism equipment, can solve the problems of increasing labor intensity of operators, difficulty in controlling lamination pressure, and low efficiency of manual operation, so as to improve operating efficiency, occupy less space for the structure, and improve the assembly process. fast and precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

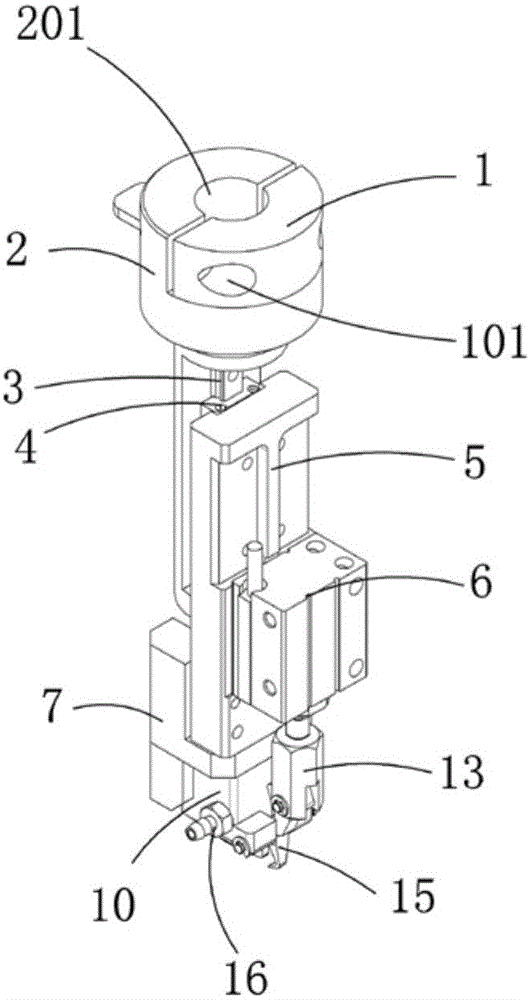

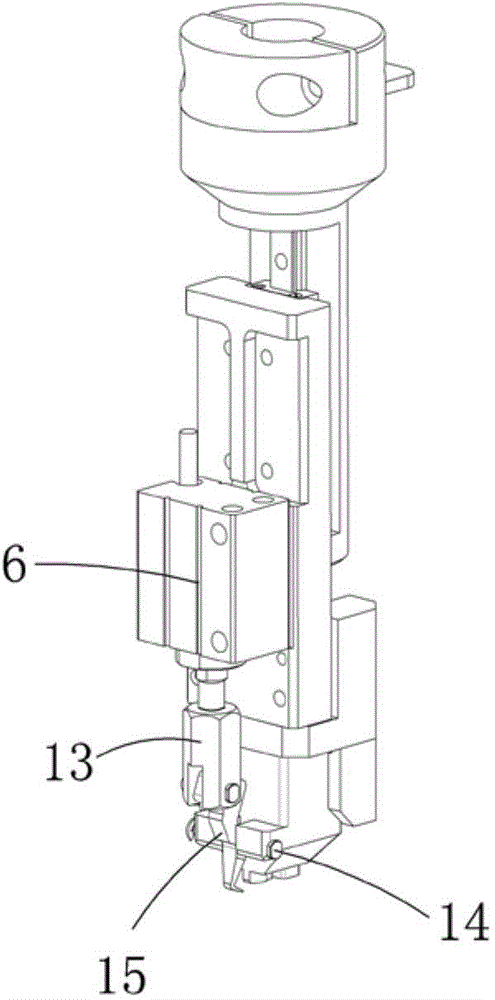

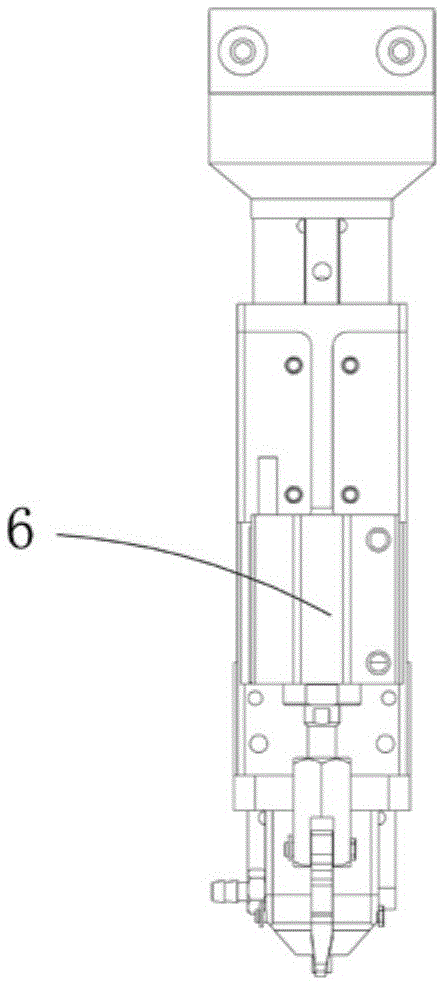

[0021] Examples, see attached Figure 1-5 , a suction rod mechanism that can absorb the acoustic mesh of a mobile phone, it includes an R-axis movable shaft 1 and an R-axis extension shaft 2, and the R-axis movable shaft is movably installed on the R-axis extension shaft; the R-axis movable shaft is a semicircle Ring structure, the upper part of the R-axis extension shaft is provided with a step and a semicircular hole 201, the R-axis movable shaft is located at the step position, and the R-axis movable shaft is provided with two connecting holes 101 in the transverse direction, through which the R-axis movable shaft can be locked Tightly mounted on the R-axis extension shaft.

[0022] The semi-circular hole on the R-axis extension shaft cooperates with the semi-circle structure of the R-axis movable shaft to form a circular slot hole, through which a four-axis manipulator can be installed on the upper ends of the R-axis extension shaft and the R-axis movable shaft, The movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com