Efficient silent air duct well structure for roof

An air duct and silent technology, which is applied to roofs, building structures, roof coverings, etc., can solve the problems of reducing the quality of roof space use and high noise, and achieve the goal of optimizing the quality of roof space, reducing roof noise, and reducing construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

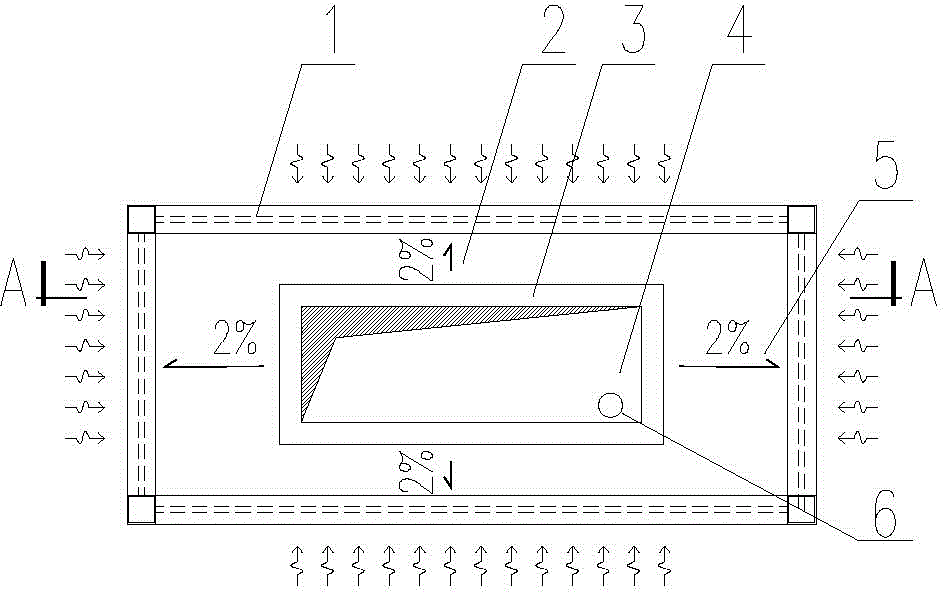

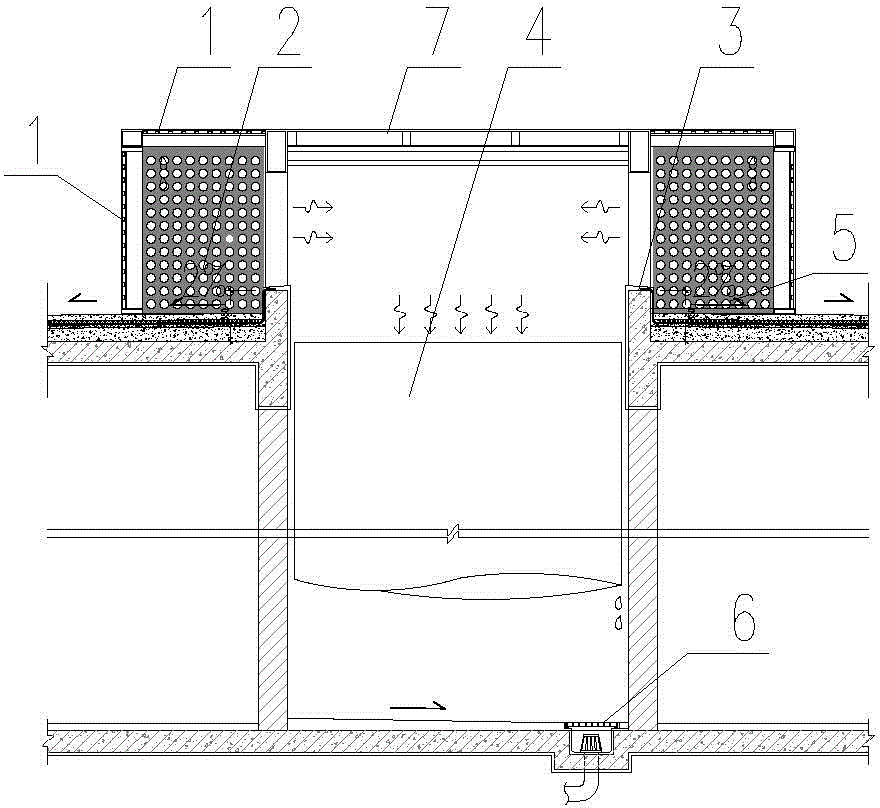

[0014] like figure 1 and figure 2 As shown: the ventilation expansion cavity 2 is set around the HVAC prefabricated air duct well 4; the ventilation perforated aluminum plate 1 is arranged on the outer four walls and the top of the ventilation expansion cavity 2; directly above the HVAC prefabricated air duct well 4 Set the aluminum plate top cover 7, the elevation of the aluminum plate top cover 7 is the same as that of the ventilation perforated aluminum plate 1 on the top; set the rain-proof concrete opening 3 around the roof civil engineering opening of the HVAC prefabricated air duct well 4, and it is generally recommended to block The height of the rain concrete turning over is 350 mm; the outward roof drainage slope 5 is made within the scope of the ventilated expansion cavity 2, that is, the high point of the drainage slope is set at the 3 places of the rainproof concrete turning over, and the low point is set at the outer four At 1 perforated aluminum plate on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com