Scaffold cross rod connector and production process thereof

A production process and scaffolding technology, applied in the connection of scaffolding, housing structure support, housing structure support and other directions, can solve problems such as affecting the orderly stacking of crossbars, achieve good economic benefits, efficient and convenient production process, and low scrap rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

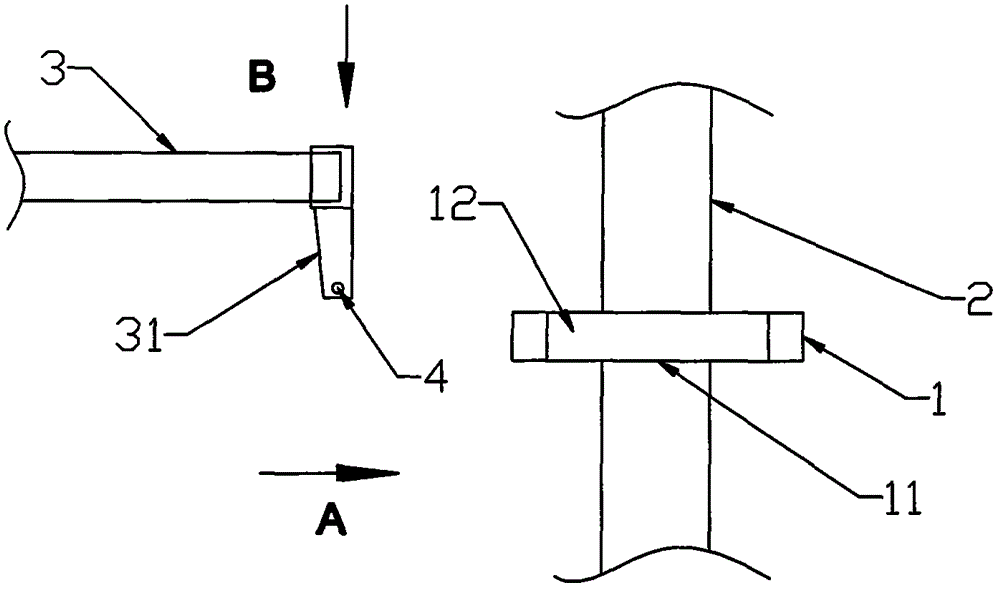

[0033] Such as Figure 5 As shown, the technical solution adopted by the scaffold crossbar joint of the present invention is: the scaffold crossbar joint 4 includes a plug pin 41, a positioning fixing joint 42, and the positioning fixing joint 42 and the plug pin 41 are integrally formed. The positioning fixing joint 42 includes two connecting reinforcing ribs 421 and two butterfly positioning pieces 422; the plug pin 41 is formed by two metal pieces 411 tightly attached along the Z axis. The bottoms of the two metal pieces 411 are connected as a whole. The cross-sectional width of the pin 41 is wide at the top and narrow at the bottom. The pin 41 has a positioning protrusion 412 on the surface close to one end of the connecting stiffener 421, and the lower end of the pin 41 has a positioning pin hole 414; the connecting stiffener 421 is made of a metal sheet 411 extends upward along the Z axis. Two butterfly positioning pieces 422 are symmetrically distributed along the Z axis....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com