Wet type cavitation erosion resisting cylinder sleeve

An anti-cavitation and cylinder liner technology, applied in the direction of cylinder, cylinder head, engine components, etc., can solve problems such as hindering the diesel engine, affecting the working reliability of the diesel engine, and the service life of the cylinder liner, so as to prevent cavitation, small deformation, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

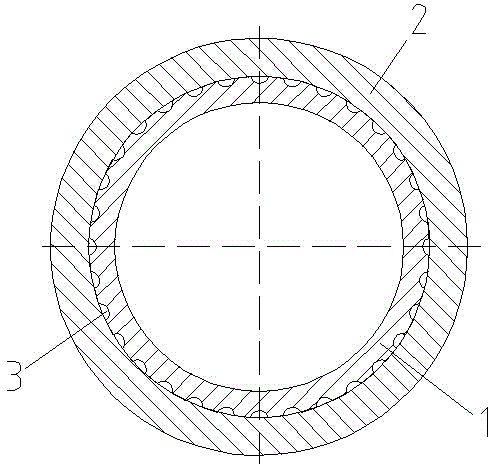

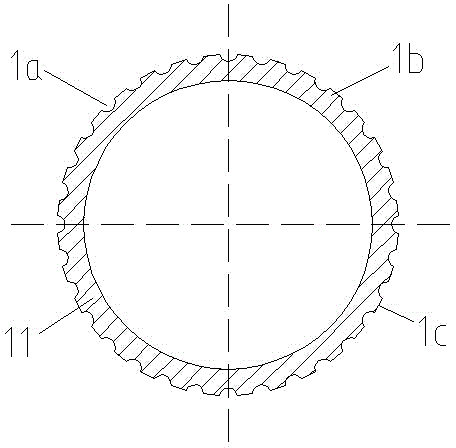

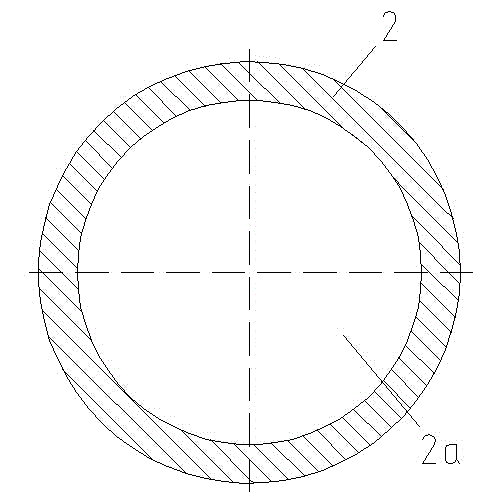

[0016] Figure 1 to Figure 3 It is a structural schematic diagram of the present invention.

[0017] The reference signs therein are: cylinder liner body 1 , water cavity groove 1 a , reinforcing rib 1 b , outer arc surface 1 c , cylinder wall 11 , engine block 2 , cylinder liner hole 2 a, cooling water cavity 3 .

[0018] Figure 1 to Figure 3 It is a structural schematic diagram of the present invention, as shown in the figure, a wet anti-cavitation cylinder liner of the present invention includes a cylinder liner body 1, the cylinder liner body 1 has a thickened cylinder wall 11, and the outer circumference of the cylinder liner body 1 Axially extending water chamber grooves 1a are processed at equal arc intervals on the surface, and reinforcing ribs 1b that can enhance the rigidity of the cylinder liner body 1 are formed between two adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com