Slurry pump sump

A slurry pump and pump pool technology, applied in the direction of pumps, non-displacement pumps, non-variable capacity pumps, etc., can solve the problem that the vicious cycle cannot be eliminated in a short time, and achieve the effect of promoting promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

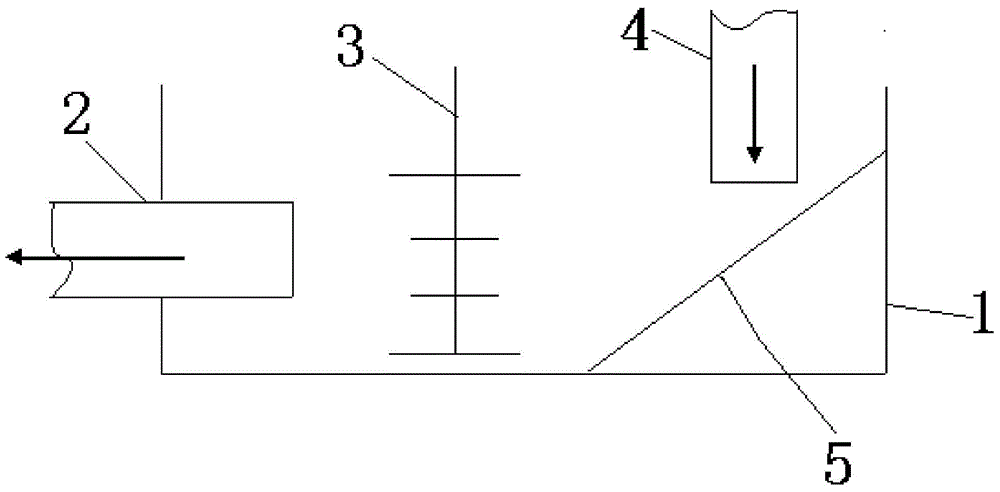

[0014] Such as figure 1 The pump pool of the slurry pump shown includes a pump pool 1, a slurry pump 2 is provided on one side of the pump pool 1, and an anti-stacking device is provided on the side opposite to the slurry pump 2 in the pump pool 1 5. A feed port 4 is provided above the anti-stacking device 5 .

[0015] The focus of the design of the present invention is to solve the problem of "slag slurry ore collection". Therefore, an anti-stockpiling device 5 is added at first, and the anti-stockpiling device 5 can guide the slurry input from the feed port 4 to the slurry pump 2 in time, fundamentally completely preventing the possibility of ore collection. Of course, the preferred and simplest structure of the anti-stocking device 5 here is exactly the material guide swash plate, such as figure 1 As shown, the sloping plate guides the slurry to flow to the slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com