Liftable wheeled support with automatic brake function

An automatic braking and lifting technology, which is applied to the mobile frame, engine frame, supporting machine, etc., can solve the problems of increasing the overall equipment volume, collision damage of the main equipment, small ground clearance, etc., and achieves strong practicability , avoid collision damage, and improve the effect of passing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

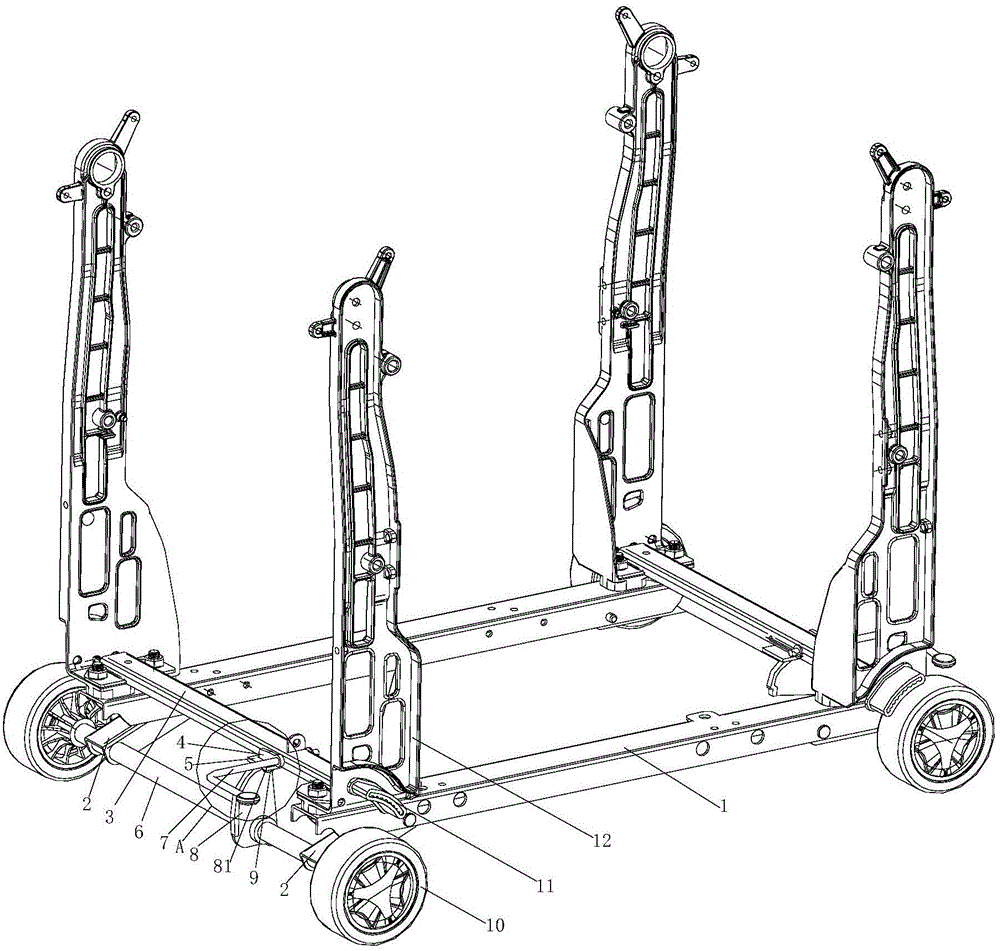

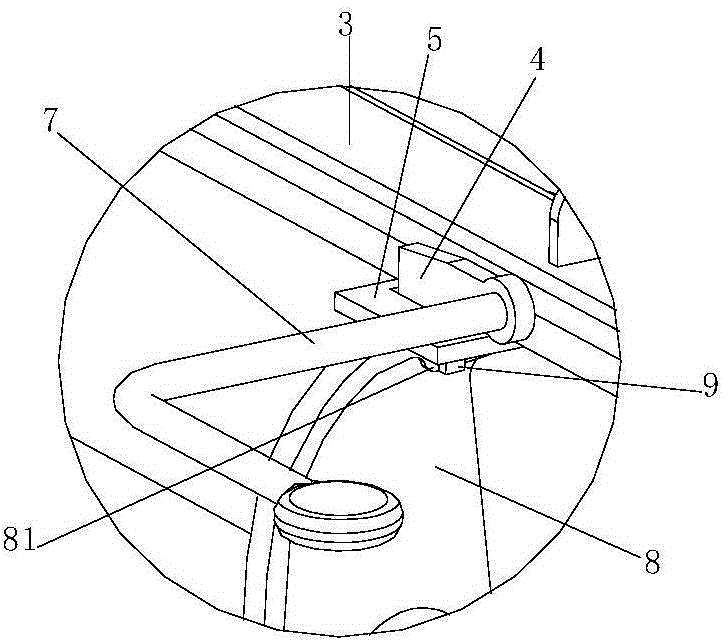

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 The enlarged view at A, as shown in the figure: the liftable wheeled support with automatic braking in this embodiment includes a walking wheel assembly and a base plate 1 for installing the main equipment, and the base plate 1 is supported by a lifting mechanism Walking wheel assembly: a brake plate is installed on the frame, and the brake plate faces the walking rotating parts of the walking wheel assembly from the radial outer edge from top to bottom, and the brake plate 11 is at the bottom when the bottom plate 1 is at a low point Brake the rotating parts; the walking wheel assembly generally includes the walking wheel and the installation parts, which will not be repeated here; the lifting mechanism can be the existing ball screw mechanism, casing mechanism, etc., all of which can achieve the purpose of lifting; when walking, the The bottom plate is raised to increase t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com