A multi-component composite integrated finned copper tube heat exchanger

A copper tube heat exchanger, multi-composite technology, used in refrigeration and liquefaction, fluid circulation arrangement, evaporator/condenser, etc. problems, to achieve the effect of saving production costs, improving heat exchange efficiency, and being widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

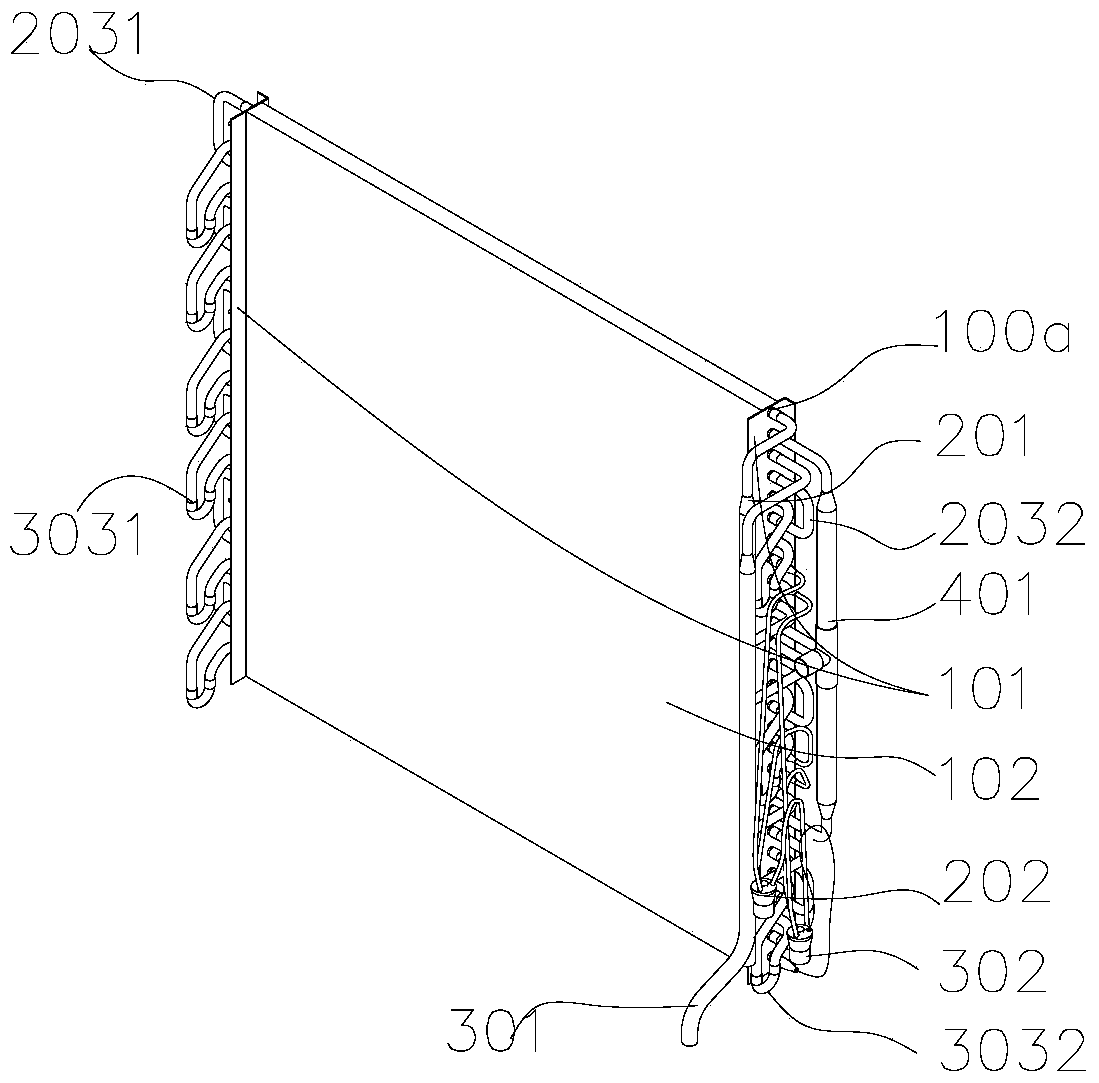

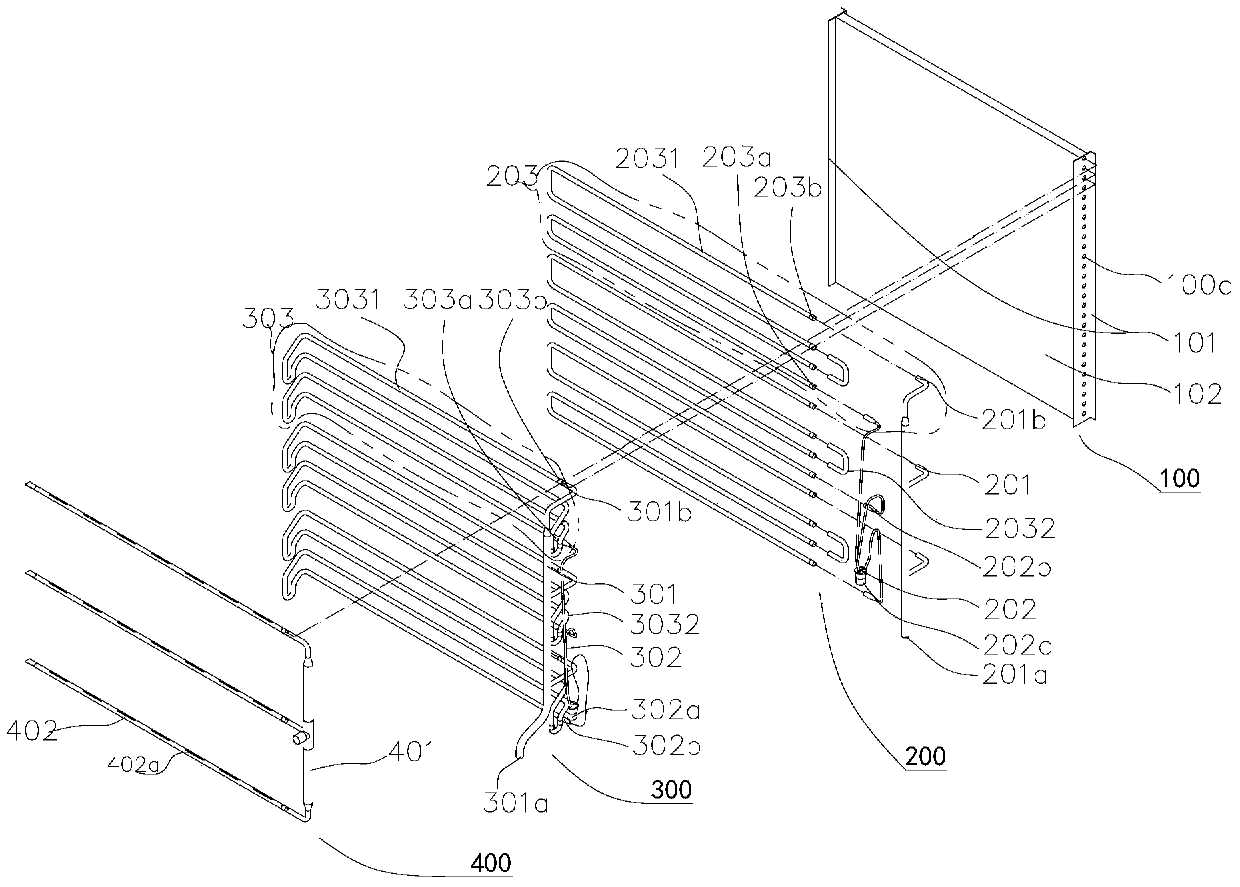

[0065] see Figure 1a-Figure 1b , the multiple composite integrated finned copper tube heat exchanger described in this embodiment includes a fin unit 100, a first heat exchanger loop piping system 200, and a second heat exchanger loop piping system 300, wherein:

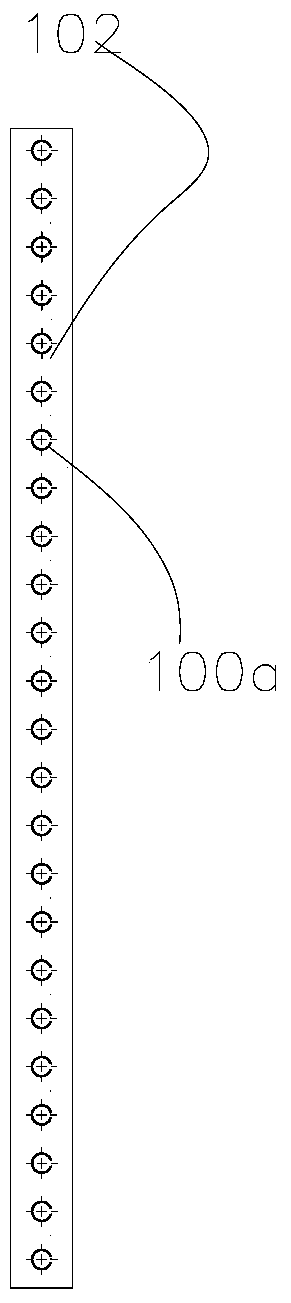

[0066] The fin unit 100 includes two side baffles 101 and several rectangular thin-walled fins 102, wherein the rectangular thin-walled fins 102 are arranged between the two side baffles 101, along the One row or several parallel rows of circular holes 100a are provided through the two side baffles 101 and the rectangular thin-walled fins 102 in the longitudinal direction, and the positions of the circular holes 100a in adjacent rows are staggered.

[0067] The first heat exchanger circuit piping system 200 includes a first starting-end circuit branch pipe 201, a first end-circuit branching pipe 202 and several groups of first sub-circuit piping systems 203, wherein the first starting-end circuit branching pipe 201 ...

Embodiment 2

[0085] The difference between embodiment 2 and embodiment 1 is:

[0086] The heat exchanger disclosed in Example 1 is a new single-row same-side multi-component composite integrated finned copper tube heat exchanger on the same side, while the heat exchanger disclosed in this embodiment is a new single-row multi-component Composite integrated finned copper tube heat exchanger.

[0087] Specifically, see Figure 9a-9b , in this embodiment, the branch pipe 201 of the first end circuit and the branch pipe 202 of the first end circuit are arranged in pairs on the outside of the side baffle plate 101 on the left side of the fin unit 100; the branch pipe 201 of the first end circuit and the branch pipe 201 of the first end circuit The branch pipes 202 are arranged in pairs on the outside of the right side baffle plate 101. This specification refers to this new multi-component composite integrated finned copper tube heat exchanger based on this arrangement as the different-side type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com