Method for determining contents of carbon and sulfur in iron-containing dust mud

A sulfur content, dust sludge technology, applied in measuring devices, material analysis through optical means, instruments, etc., to achieve the effect of increasing the reaction temperature, high precision, and lowering the melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

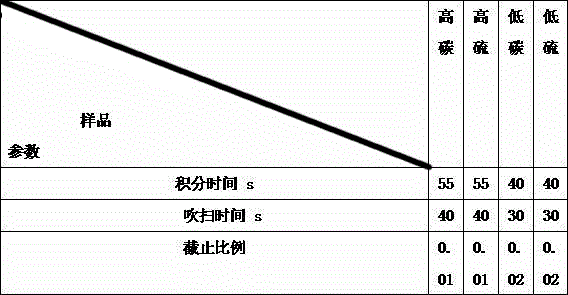

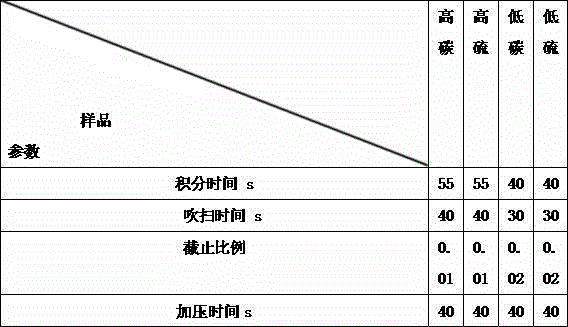

Image

Examples

preparation example Construction

[0060] 1) Preparation of sulfur standard series

[0061] Weigh 2.174g (accurate to 0.0002g) of potassium sulfate (standard reagent) solid into a 100mL volumetric flask, add 20mL of high-purity water to dissolve, dilute to the mark, and shake well. At this time, the volume of the solution is 4.00mg. mL -1 .

[0062] Weigh 10.87g (accurate to 0.0002g) of potassium sulfate (standard reagent) solid into a 100mL volumetric flask, add 20mL of high-purity water to dissolve, dilute to the mark, and shake well. At this time, the volume of the solution is 20.00mg. mL -1 .

[0063] Use a micropipette to take different amounts of potassium sulfate reference solution (so that the sulfur content: low sulfur 0.002 at% to 0.500 at%, high sulfur 0.500 at% to 12.00 at% each 10 points) into the cleaned and dried tin capsule After drying at 80℃~90℃ for 2 hours, flatten and fold it, put it into a burnt crucible covered with 0.3 g of pure iron flux, and then cover with 1.5g of tungsten powder f...

Embodiment 1

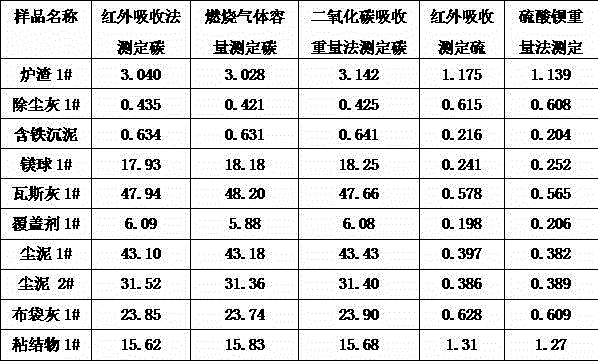

[0073] Embodiment 1: method comparison

[0074] Method comparison experiments were carried out by using infrared absorption method and barium sulfate gravimetric method to measure sulfur content, combustion gas capacity to measure carbon content, and carbon dioxide absorption gravimetric method to measure carbon. The results are shown in Table 1

[0075] Table 1 method comparison at%

[0076]

Embodiment 2

[0077] Embodiment 2: standard addition method

[0078] Quantitatively weigh iron-containing dust samples, slag, and ore standard samples, add different amounts of potassium sulfate benchmarks, and use potassium sulfate benchmarks, ore, and slag standard samples to calibrate the working curve according to the method described under the same instrument conditions. (Using multi-point calibration) to determine the sulfur content in the sample. see table 2

[0079] Table 2 Accuracy at%

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com