MRI (Magnetic Resonance Imaging) gradient coil assembling platform and assembling method

A gradient coil and assembly platform technology, which is applied in the direction of measuring devices, measuring magnetic variables, instruments, etc., can solve the problems of inability to realize high-speed gradient switching, restrict the development of imaging technology, and affect the performance of coils, so as to achieve automatic search and easy use , the effect of simplifying the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

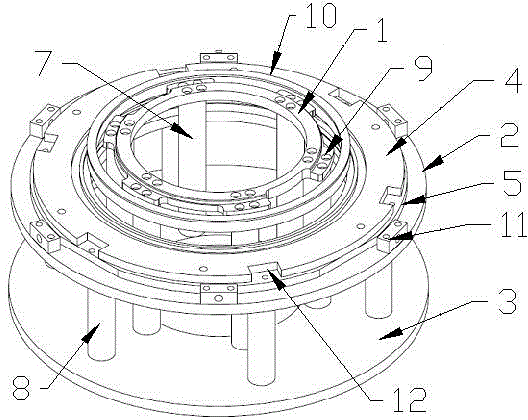

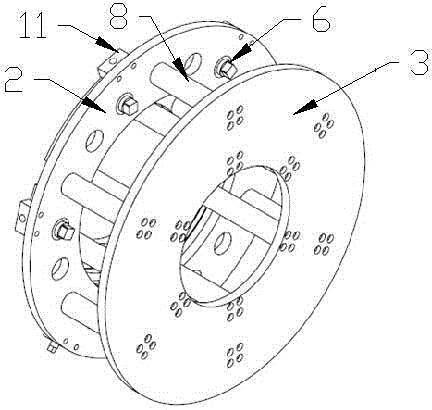

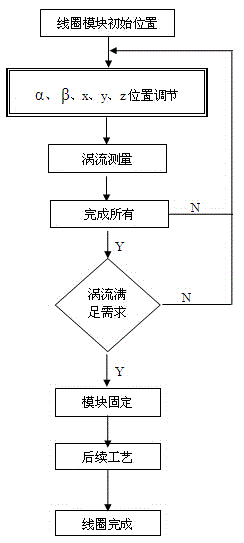

[0025] Such as figure 1 , figure 2 An MRI gradient coil assembly platform according to the present invention is shown, including a load-bearing structure 1, a load-bearing structure 2, a bottom installation platform 3, an X, Y adjustment platform 4, a rotation adjustment platform 5, and a Z-direction oblique adjustment bolt 6 , the bottom installation platform 3 is ring-shaped, and there are two rings of support columns inside and outside the ring part, which are respectively the inner layer support column 7 and the outer layer support column 8, and the inner layer support column 7 supports the load-bearing structure. 1. The outer support column 8 supports the ring-shaped load-bearing structure 2, the load-bearing structure 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com