hedge trimmer

A technology of hedge trimmer and driving mechanism, which is applied in the field of hedge trimmers, can solve the problems that the safety of trimmers is difficult to be guaranteed, it is difficult to meet the requirements of trimming quality, and the workload of trimmers is increased, so as to achieve diversified and broad trimming conditions. Market application prospect, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

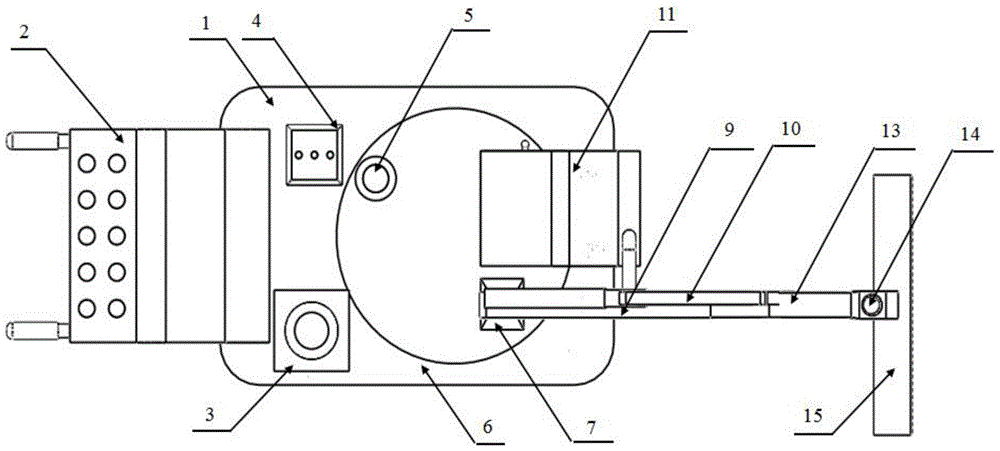

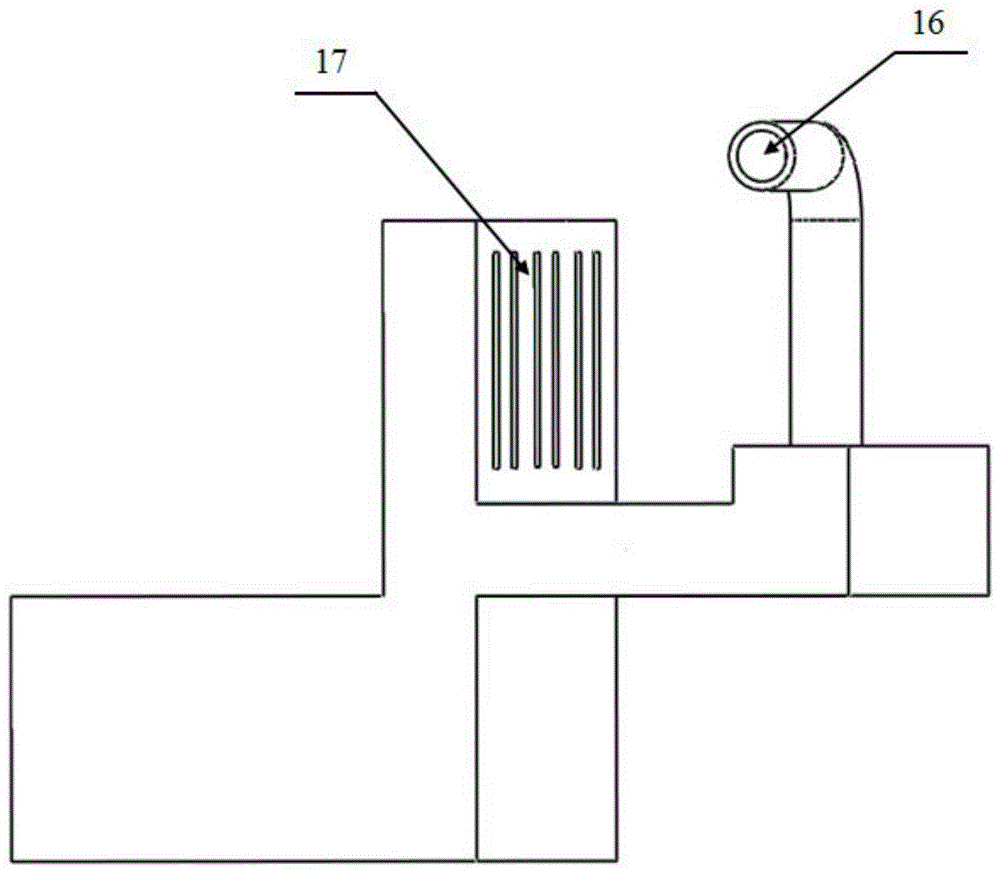

[0031] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

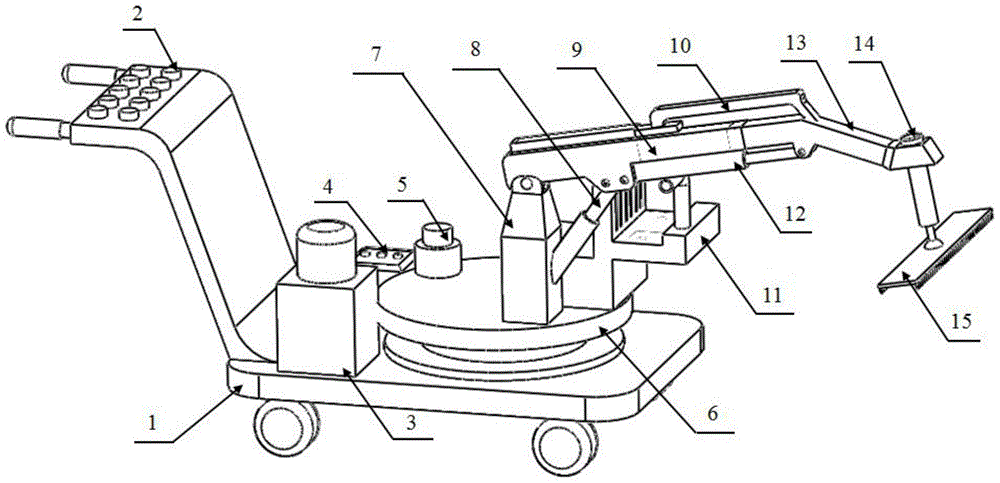

[0032] Such as Figure 1~5 Shown, a kind of hedge trimmer, it comprises:

[0033] Car body 1; the car body 1 can be in the form of a trolley.

[0034] The chassis turning device includes a chassis 6 and a chassis driving mechanism 5, the chassis 6 is rotatably installed on the car body 1, and the chassis driving mechanism 5 drives the chassis 6 to rotate on the car body 1; the chassis driving mechanism 5 can be realized by using the following structure : large gear, small gear and motor, the motor is installed on the chassis 6, the small gear is set on the output shaft of the motor, the large gear is installed on the car body 1, the small gear and the large gear are meshed, and the small gear is moved by the motor. Walk on the outer edge of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com