Horizontal multi-functional bristle trimming machine

A multi-functional, hair trimming machine technology, applied in the direction of brushes, etc., can solve the problems of few brush styles, small trimming range, single trimming angle of the brush, etc., to achieve the effect of increasing the style and increasing the trimming angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-8 The application is described in further detail.

[0043] The embodiment of the present application discloses a horizontal multifunctional trimming machine.

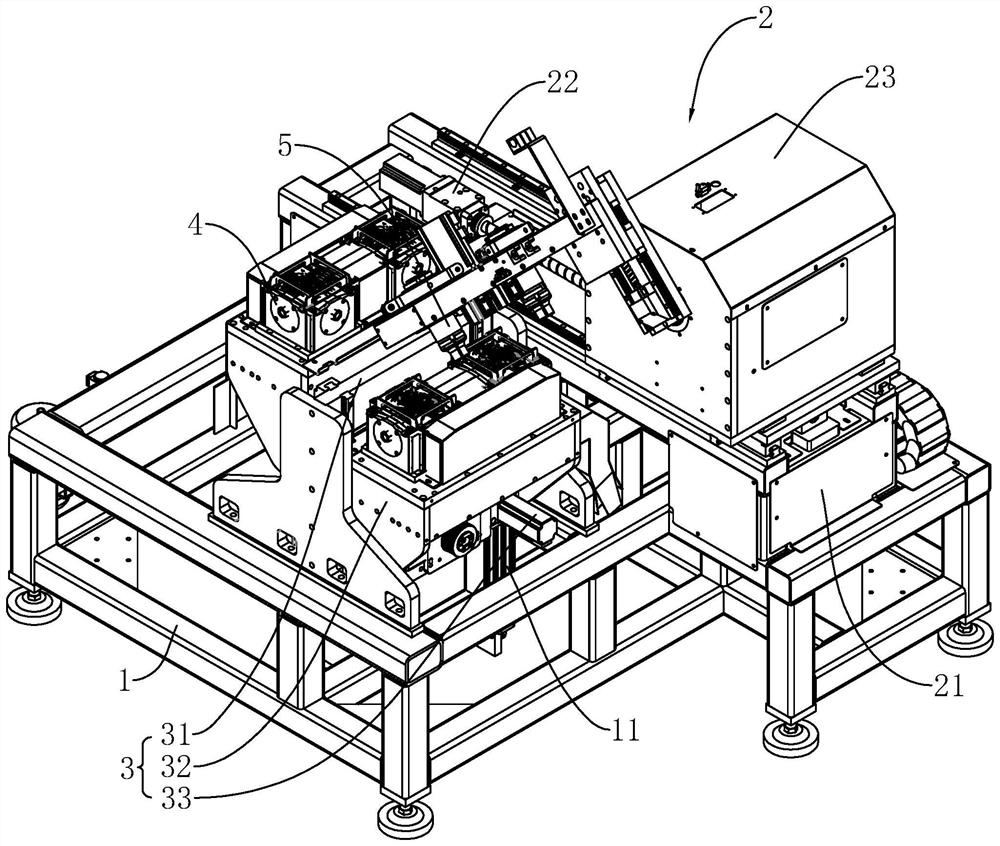

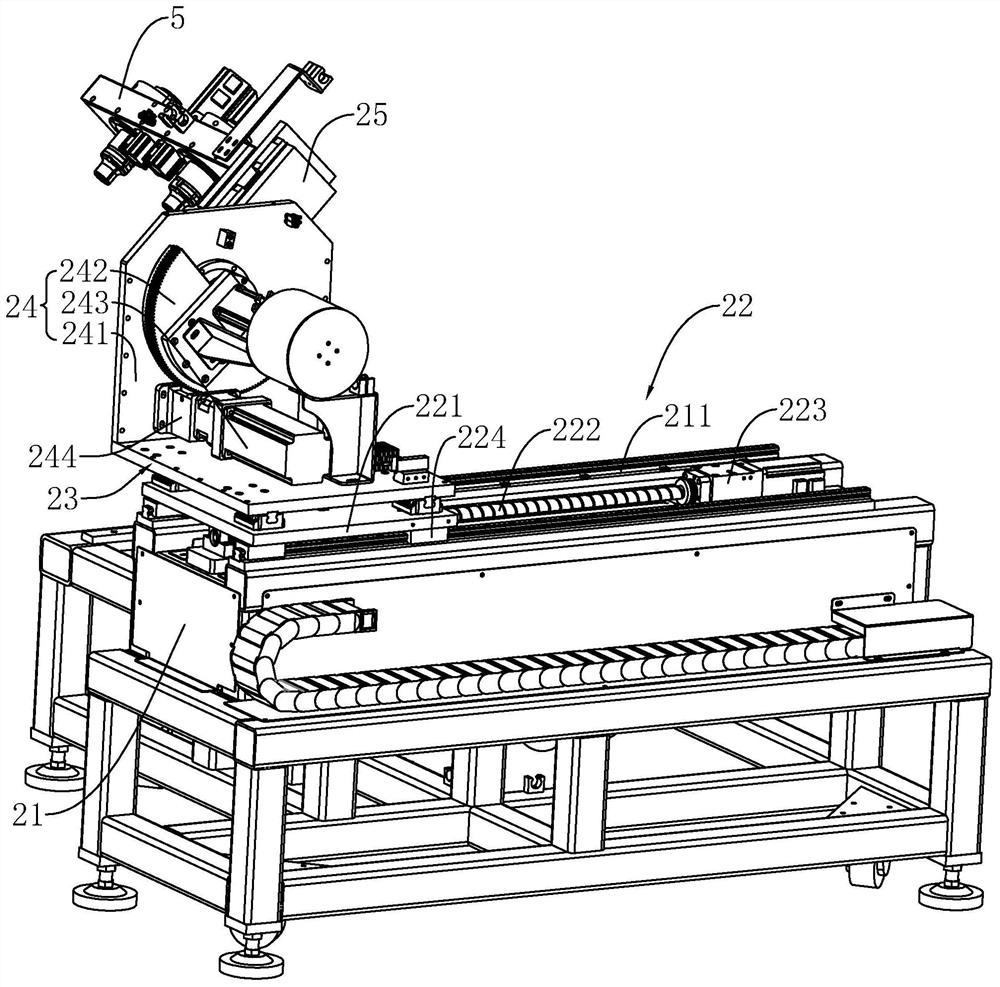

[0044] refer to figure 1 , the trimming machine includes a frame body 1, a sliding mechanism 2 located on one side of the frame body 1 and sliding along the horizontal direction, a lifting mechanism 3 is installed in the frame body 1 to slide along the vertical direction, and a pair of brushes is connected to the lifting mechanism 3 The cutting tool 4 for trimming is equipped with a clamp 5 for clamping the workpiece on the slide mechanism 2 .

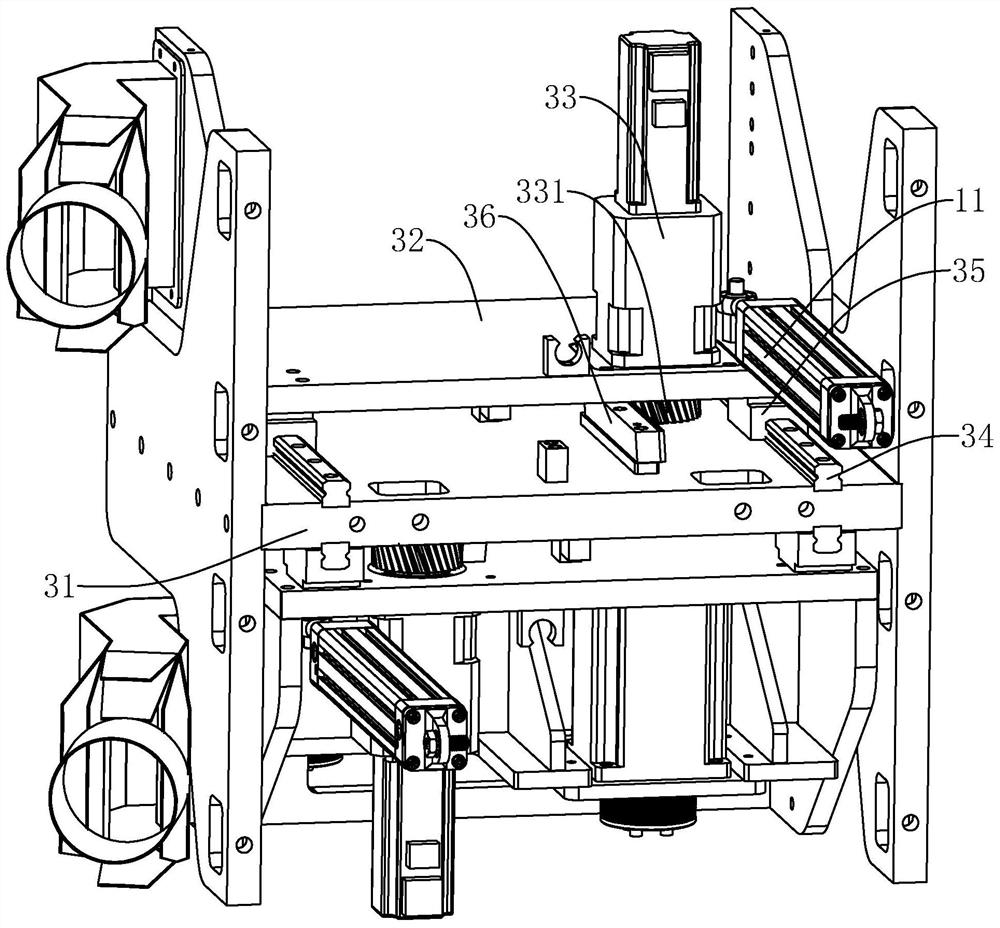

[0045] refer to figure 1 The elevating mechanism 3 includes a clapboard 31 that is vertically fixedly connected to the organic body, a support 32 that is slidably installed on both sides of the clapboard 31 along the vertical direction, an elevating motor 33 that is installed on the support 32 and drives the slide of the support 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com