Purple sweet potato beverage and instant solid powder thereof

A technology of solid powder and purple sweet potato powder, which is applied in the field of food processing to achieve the effect of uniform temperature, low temperature and good drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

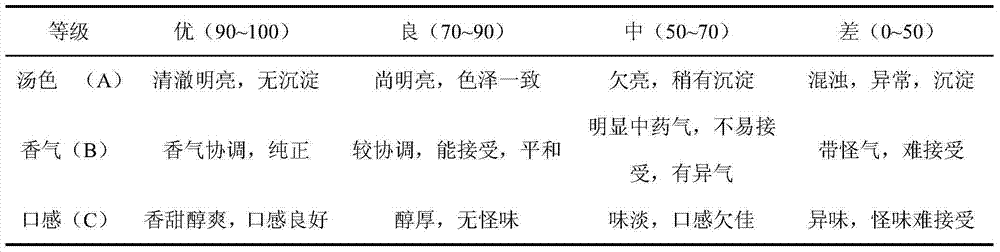

Examples

Embodiment 1

[0022] A purple sweet potato instant solid powder is prepared by the following method:

[0023] 1) Colloid mill: Take 0.95 parts of purple sweet potato powder, add 9.8 parts of water, 0.1 part of tartaric acid, and 0.3 parts of potassium hydrogen tartrate, stir and mix evenly, then pour into the colloid mill for refining, adjust the pore size of the colloid mill to make the particle size between 15 to 30 microns to obtain purple sweet potato pulp.

[0024] 2) Filtration: Pour the purple sweet potato pulp into 300-mesh gauze and filter to obtain the purple sweet potato extract.

[0025] 3) Preparation of instant purple sweet potato solid beverage: Take 9 parts of purple sweet potato extract and carry out microwave vacuum drying, microwave frequency 2450MHz, microwave equipment power 28KW, vacuum pump power 4KW, drying temperature 40°C-75°C, drying time 38min. Put the dry matter into a pulverizer for crushing, pass through a 40-mesh sieve to obtain instant purple sweet potato p...

Embodiment 2

[0027] A purple sweet potato instant solid powder is prepared by the following method:

[0028] 1) Colloid mill: Take 1.1 parts of purple sweet potato powder, add 11 parts of water, 0.3 parts of tartaric acid, and 0.1 part of potassium hydrogen tartrate, stir and mix evenly, then pour into the colloid mill for refining, adjust the pore size of the colloid mill, so that the particle size is between 15 to 30 microns to obtain purple sweet potato pulp.

[0029] 2) Filtration: Pour the purple sweet potato pulp into 300-mesh gauze and filter to obtain the purple sweet potato extract.

[0030] 3) Preparation of instant purple sweet potato solid beverage: take 10.5 parts of purple sweet potato extract and carry out microwave vacuum drying, microwave frequency 2450MHz, microwave equipment power 28KW, vacuum pump power 4KW, drying temperature 40°C-75°C, drying time 38min. Put the dry matter into a pulverizer for crushing, pass through a 40-mesh sieve to obtain instant purple sweet pot...

Embodiment 3

[0032] A purple sweet potato instant solid powder is prepared by the following method:

[0033] 1) Colloid milling: Take 1 part of purple sweet potato powder, add 10.5 parts of water, 0.2 parts of tartaric acid, and 0.2 parts of potassium hydrogen tartrate, stir and mix evenly, then pour into the colloid mill for refining, adjust the pore size of the colloid mill to make the particle size between 15 to 30 microns to obtain purple sweet potato pulp.

[0034] 2) Filtration: Pour the purple sweet potato pulp into 300-mesh gauze and filter to obtain the purple sweet potato extract.

[0035] 3) Preparation of instant purple sweet potato solid beverage: take 10 parts of purple sweet potato extract and carry out microwave vacuum drying, microwave frequency 2450MHz, microwave equipment power 28KW, vacuum pump power 4KW, drying temperature 40°C-75°C, drying time 38min. Put the dry matter into a pulverizer for crushing, pass through a 40-mesh sieve to obtain instant purple sweet potato...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap