Elevating mechanism of noodle cooker

A lifting mechanism and noodle cooking machine technology, which is applied to lifting devices, cooking utensils, household utensils, etc., can solve the problems of insufficient product precision, complex structure, and high maintenance costs, and achieve products with fewer parts, ingenious and reasonable design, and high product quality. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

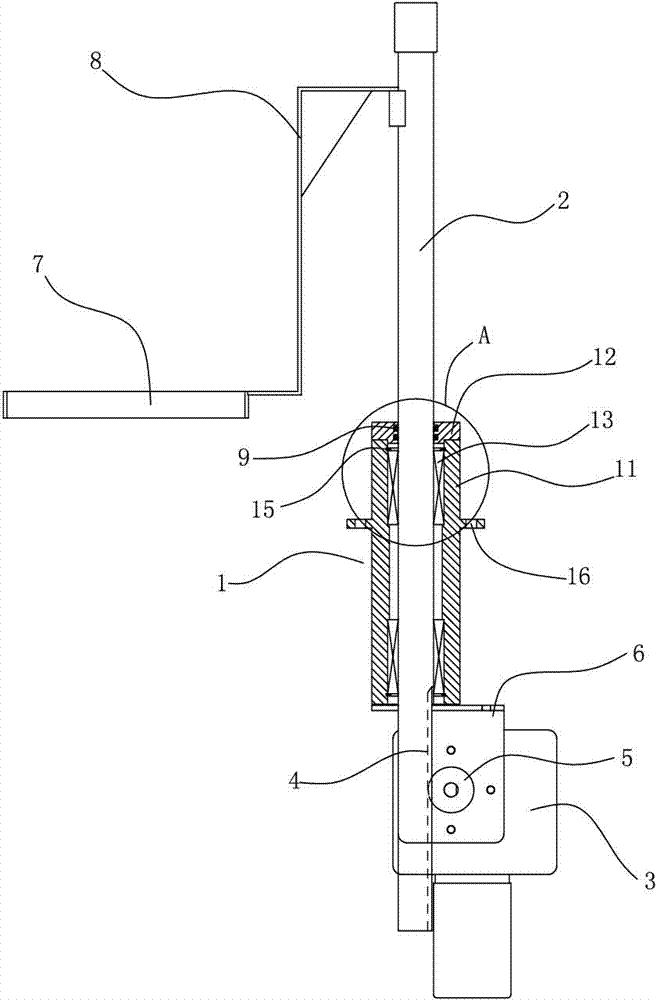

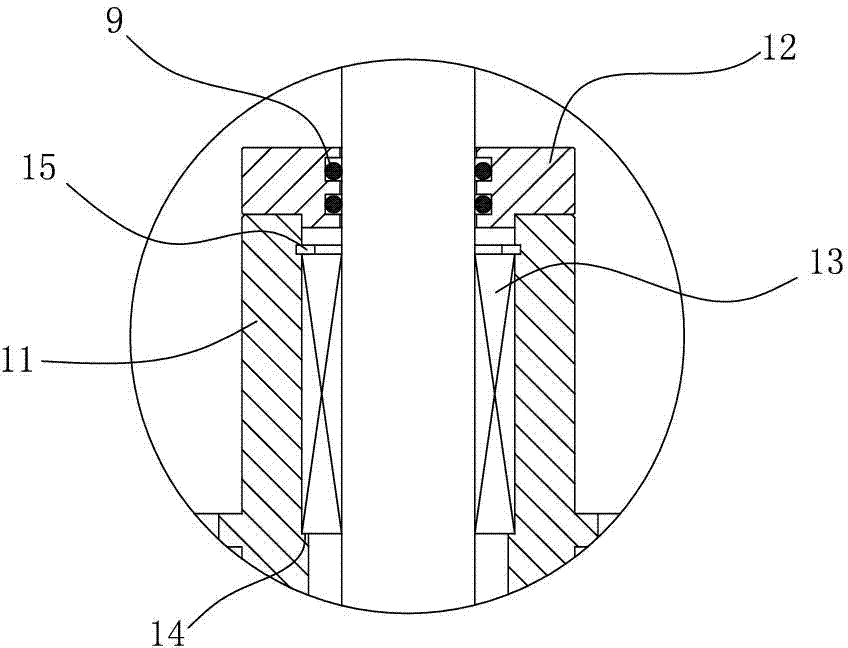

[0020] Example: such as figure 1 and figure 2 As shown, the lifting mechanism of a noodle cooking machine of the present invention includes a fixed base 1, a lifting rod 2 and a driving device 3, and the lifting rod 2 is vertically arranged on the fixing base 1 so that it can move up and down, and the lifting rod 2 A rack 4 is arranged on it, the driving device 3 is set corresponding to the elevating rod 2 , and a gear 5 meshing with the rack 4 is arranged on the output end of the driving device 3 . Since the elevating rod 2 is vertically installed and inserted into the fixed seat 1, the elevating rod 2 will not shake, and the rise or fall of the elevating rod 2 is controlled by the rack 4 and the driving device 3, and there are few parts, thereby reducing the noise source. The simple product structure makes the volume of the lifting mechanism small, so that the volume of the noodle cooking machine can be further reduced, the space occupied by the noodle cooking machine can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com