Sintered plate stick type filter

A technology of filters and plates and rods, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. The effect of using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

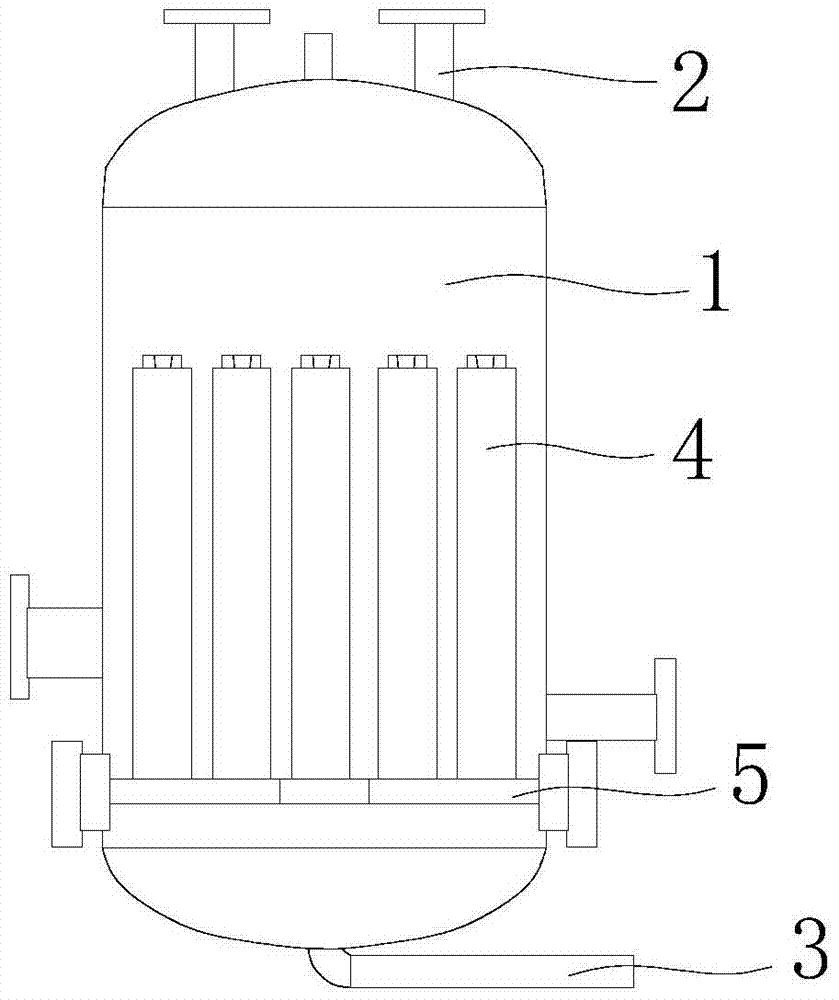

[0012] Such as figure 1 As shown, the sintered rod filter includes a filter chamber cover 1, an air intake pipeline 2 at the top and an exhaust pipeline 3 at the bottom, the filter chamber cover 1 and the sealing ring 5 set on the base After closing, the filter chamber cavity is formed, and the filter chamber cavity communicates with the exhaust pipeline 3 through the rod-type filter element 4 arranged on the base. The rod-type filter element 4 includes a cylindrical stainless steel sintered mesh and an activated carbon core inside.

[0013] Further, the surface of the stainless steel sintered mesh is provided with filter core holes, and the diameter of the filter core holes is 3-1000 μm.

[0014] Further, the bottom of the stainless steel sintered mesh is provided with threads, which are connected to the base by rotating and installing.

[0015] The embodiments of the present invention have been described in detail above, but the content described is only a preferred embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com