Rotary fixture positioning method and rotary fixture positioning device

A positioning method and fixture technology, applied in positioning devices, automatic control devices, clamping, etc., can solve problems such as the size of the processing surface not meeting the design requirements, mechanical and mechanical errors, inconsistent initial positions of the fixtures, etc., to achieve strong practicability, Eliminate mechanical errors and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

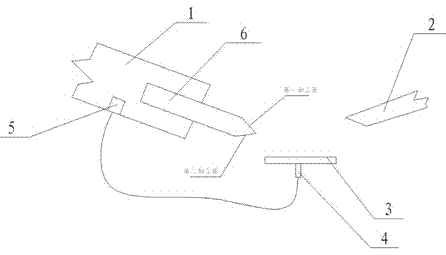

Image

Examples

Embodiment Construction

[0009] The following is a further detailed description of the present invention in conjunction with the accompanying drawings, but not as any limitation to the present invention.

[0010] An embodiment of the present invention: a positioning method of a rotatable clamp, characterized in that: a positioning plate is set between the clamp and the processing tool, and after the workpiece is clamped on the clamp, the workpiece When processing one side, first place the workpiece on the positioning plate through the fixture, and the pressure sensor on the positioning plate obtains a certain value, which penetrates into the fixture control device, and the control device uses this value as the standard coordinate of the fixture , After finishing the processing of the first side with the processed part, when performing the second side processing, place the back processed part on the positioning plate until the value of the pressure sensor reaches the value of the first number of times. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com