Material analysis and detection method based on image recognition technology

An image recognition and detection method technology, applied in the field of material analysis and detection based on image recognition technology, can solve the problems of slow growth cycle of employees' skill level, inability to ensure misjudgment by observers, mixed parts and material grades, etc. The effect of high accuracy and rapid cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

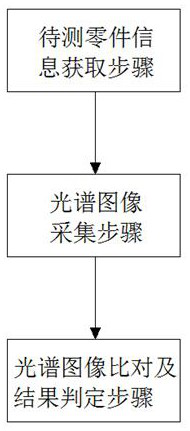

[0045] This embodiment discloses a material analysis and detection method based on image recognition technology, which specifically includes the following steps:

[0046] Steps for obtaining the information of the parts to be tested: Before testing, first use the label recognizer to scan the identification label of the part to be tested to obtain the detection quantity of the part to be tested and the brand name of the part, and then the label recognizer transmits the above part information to the host computer , the host computer searches and matches in the stored database according to the above part information, and finally determines the standard spectrum for comparison;

[0047] Spectral image acquisition steps: put the part to be tested on the detection platform of the spectrum mirror, turn on the switch, the host computer first stimulates the spectrum mirror to generate sparks, then controls the rotation of the servo motor, and the servo motor drives the knob of the spect...

Embodiment 2

[0050]This embodiment discloses a material analysis and detection method based on image recognition technology. On the basis of Embodiment 1, this embodiment makes further limitations and explanations for the analysis and detection method. In this embodiment, In the spectral image collection step, the splicing of multiple spectral images collected in order using the coordinate system specifically refers to splicing the rightmost edge of the first picture with the left edge of the second picture, and the new The height of the picture is the same as the original two Figure 1 Coherent, and the width is the sum of the two pictures.

[0051] Further, the spectral image comparison and result determination step specifically includes the following steps:

[0052] Image digitization steps: first convert the RGB color value of each pixel on the inspection spectrum image of the part to be tested into the gray value of the pixel through the following calculation expression

[0053] S=1...

Embodiment 3

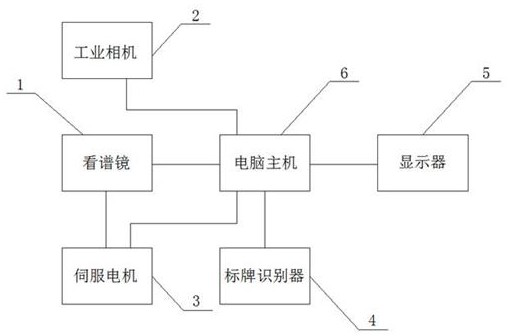

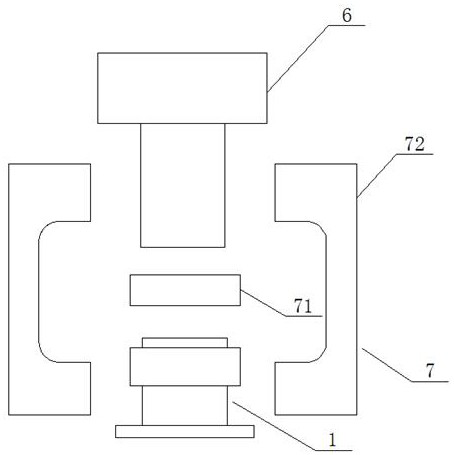

[0082] This embodiment discloses a material analysis and detection device based on image recognition technology. figure 2 , mainly including spectroscope 1, industrial camera 2, servo motor 3, signage recognizer 4, display 5 and computer host 6, said computer host 6 is connected with spectroscope 1, industrial camera 2, servo motor 3, signage recognition respectively Device 4 and display 5 are connected, and it is the control terminal of the whole device. The spectrum mirror 1 is a prior art, and it is a finished product on the market. The industrial camera 2 is arranged on the spectrum mirror 1 through the camera mount 7. On the eyepiece, the output end of the servo motor 3 is connected with the knob on the spectroscope 1, and the label identifier 4 is an RFID reader.

[0083] Further, refer to the attached figure 2 , the camera mount 7 includes a lens adapter ring 71 and a camera bracket 72, one end of the lens adapter ring 71 is connected with the lens of the industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com