A wheel assembly for an aerial work platform

An aerial work platform and wheel technology, which is applied to vehicle components, lifting devices, steering mechanisms, etc., can solve the problems of unreasonable structural design, complex structural layout, and high manufacturing costs, achieve a simple and practical overall structure, avoid steering asynchrony, Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

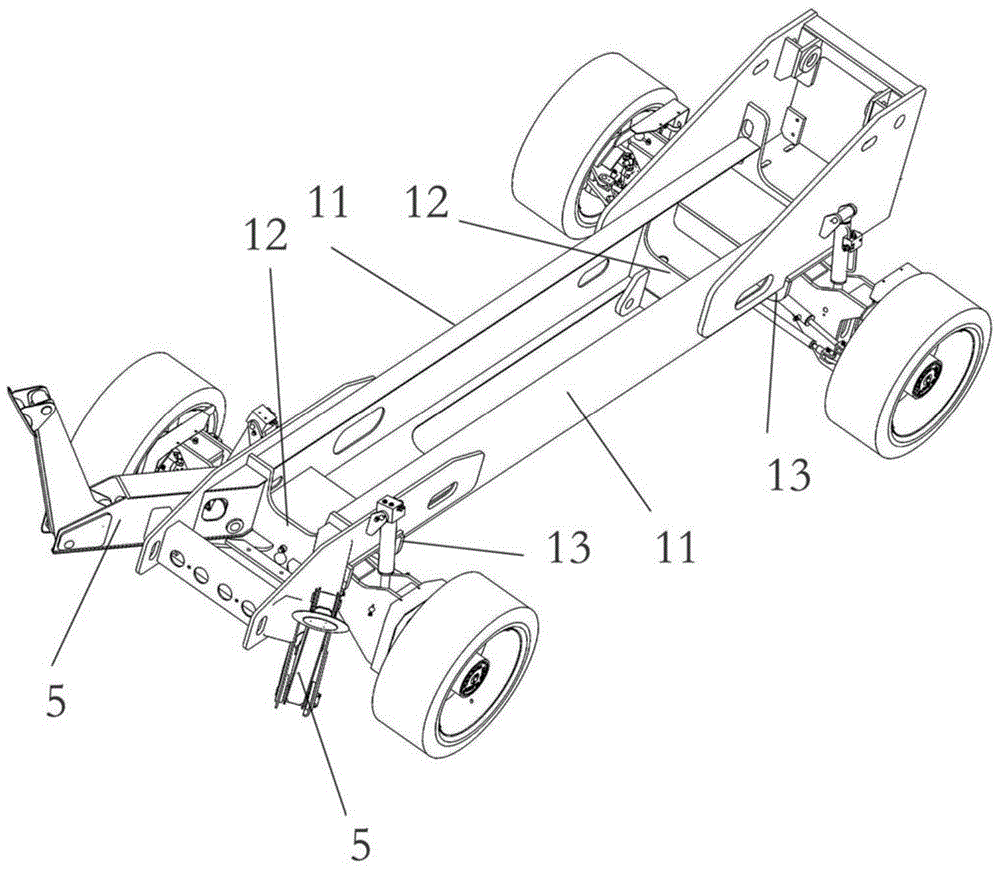

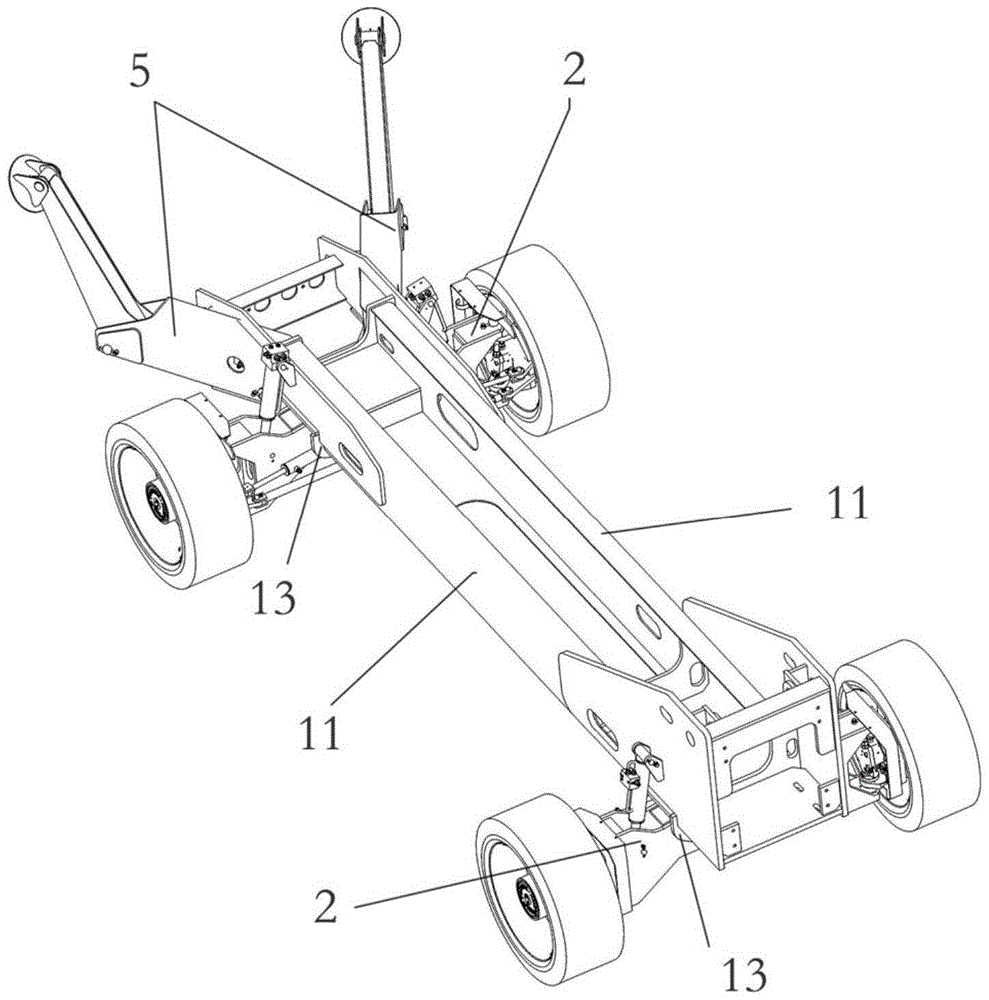

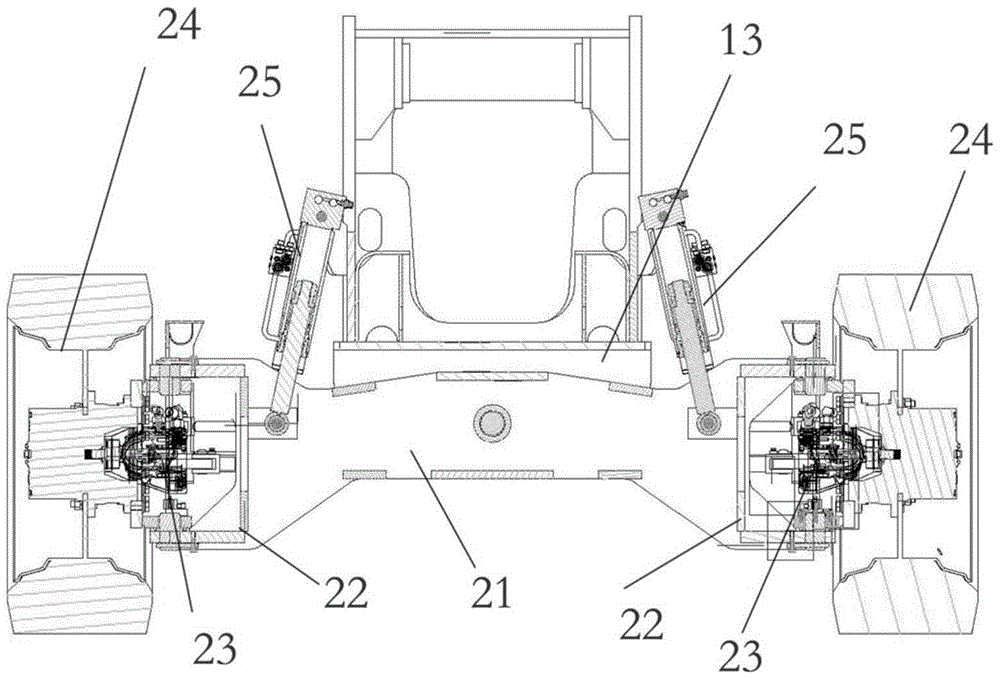

[0019] see Figure 1-Figure 6 , this embodiment This embodiment is used for the chassis assembly of the aerial work platform, including the machine base assembly 1 and the wheel assembly 2, wherein the machine base assembly 1 includes two girders 11, and is used to connect the two girders 11 A plurality of girder connecting plates 12 and two wheel assembly mounts 13 for mounting the wheel assembly 2, the two wheel assembly mounts 13 are respectively provided at the front and rear ends of the girder 11, and the wheel assembly mounts 13 are integral The overall structure is stamped from a steel plate. The wheel assembly mounting seat 13 is provided with a U-shaped wheel assembly mounting groove. The wheel assembly 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com