Integrated double-blockage double-discharge ball valve

An integral, ball valve technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of poor sealing effect, easy liquid leakage, easy leakage, etc., and achieve stable rotating connection and good sealing. , the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

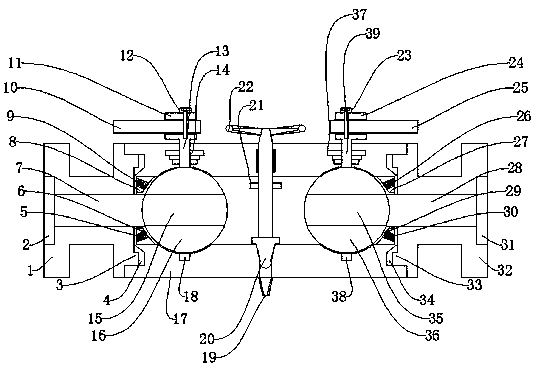

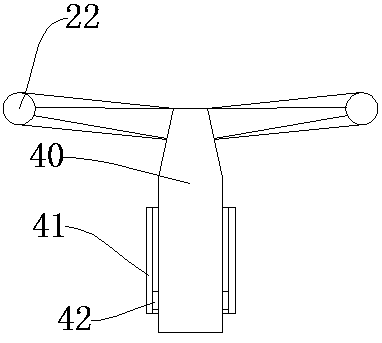

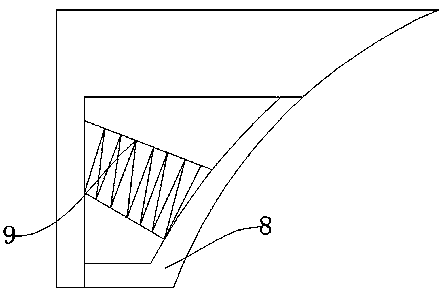

[0030] Such as Figure 1-Figure 4As shown, an integral double-blocking and double-discharging ball valve includes No. 1 connecting pipe 1, valve body 17 and No. 2 connecting pipe 32. The side of the valve body 17 away from the No. 1 connecting pipe 1 is provided with the two The No. 1 connecting pipe 32, the No. 1 connecting pipe 1 is provided with a No. 1 sealing gasket groove 2 on the side away from the valve body 17, and the No. 1 connecting pipe 1 is provided with a No. 1 pipe hole 7 inside. The No. 1 connecting pipe 1 One side of the valve body 17 is provided with a No. 1 tube protrusion 3, and the No. 1 tube protrusion 3 is provided with a No. 1 tube sealing ring 4 near the side of the valve body 17. The No. 1 tube sealing ring 4 can make the No. 1 tube The connection between the connecting pipe 1 and the valve body 17 is stable, and a No. 1 lower spring 5 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com