A kind of halogen-free flame-retardant f-class high-temperature-resistant polyester heat-shrinkable tube for electrician and preparation method thereof

A high-temperature-resistant polyester and heat-shrinkable tube technology, applied in the field of heat-shrinkable tubes, can solve the problem that the long-term use temperature of heat-shrinkable materials cannot exceed 155°C, and achieve the effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

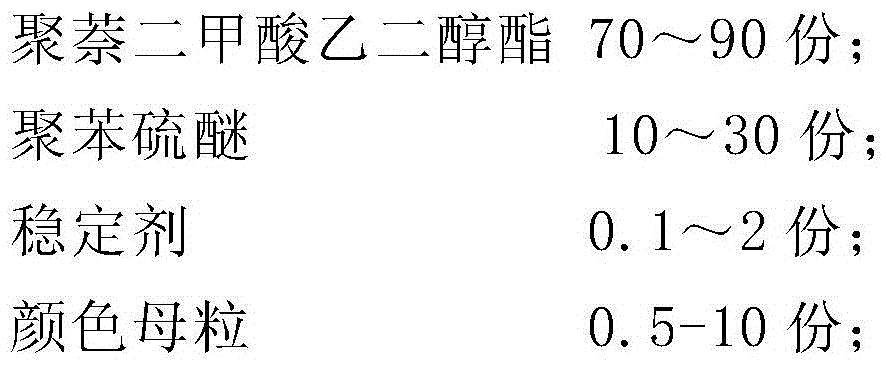

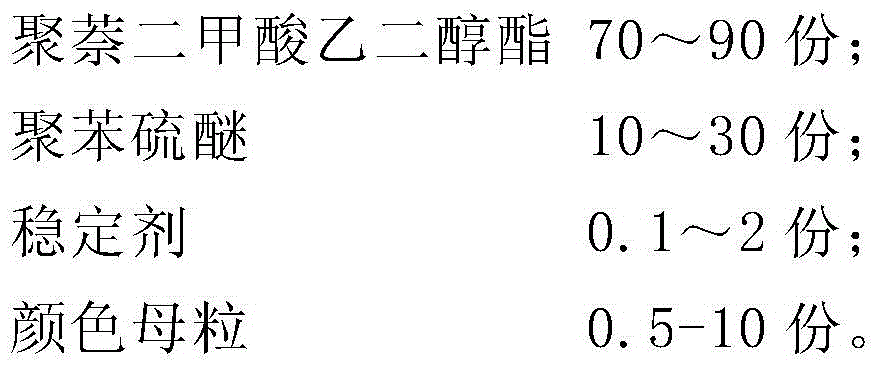

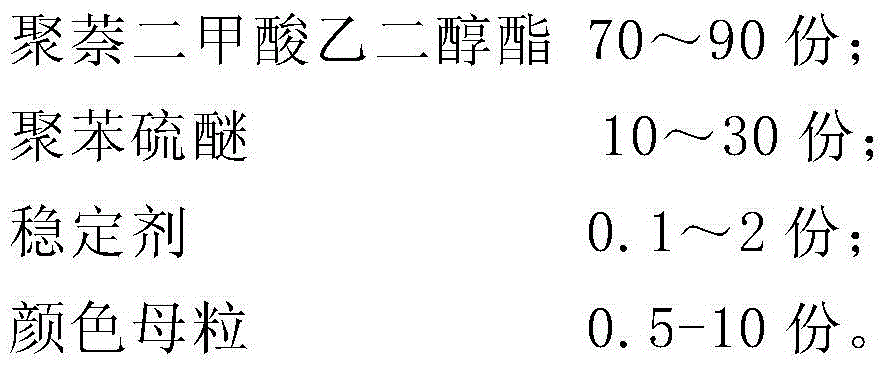

[0022] The present invention proposes a halogen-free flame-retardant F-grade high-temperature-resistant polyester heat-shrinkable tube for electricians, which consists of the following components in parts by weight:

[0023]

[0024] The polyethylene naphthalate is a polyester material formed by polycondensation of dimethyl 2,6-naphthalene dicarboxylate (NDC) and ethylene glycol (EG), or 2,6-naphthalene Diformic acid (NDA) and ethylene glycol (EG) polycondensation.

[0025] The chemical structure of polyethylene naphthalate is similar to that of polyethylene terephthalate (PET), and polyethylene terephthalate (PET) is replaced by a more rigid naphthalene ring in the molecular chain The benzene ring in.

[0026] The polyethylene naphthalate has a melting point of 260-265°C, a glass transition temperature of 120°C-130°C, and an intrinsic viscosity of not less than 0.80dl / g;

[0027] The chemical name of polyphenylene sulfide is polyphenylene sulfide. It is a material made o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com