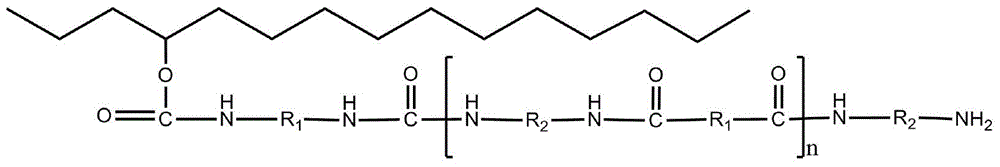

A polyurea type anti-settling agent

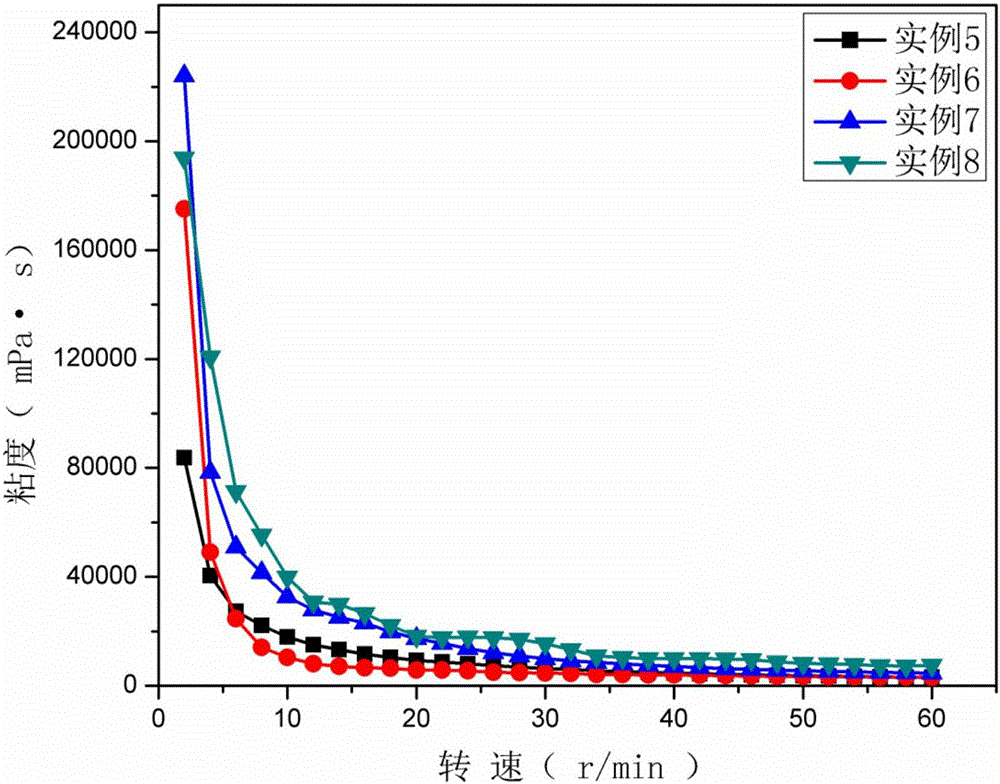

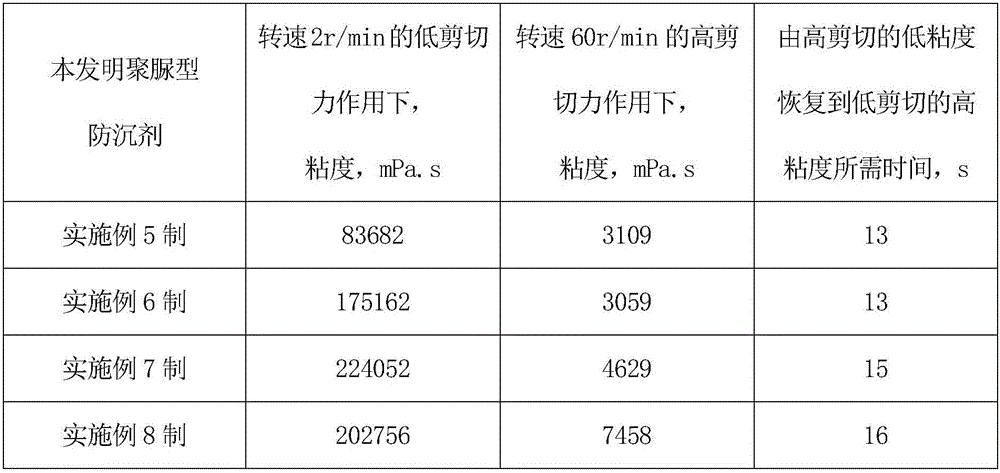

An anti-settling agent and polyurea technology, applied in the field of one-component high-temperature baking coatings, one-component thermoplastic coatings, and two-component polyurethane coatings, it can solve the problem that non-aqueous dispersion resins have poor thixotropic effect and chemical resistance. Unsatisfactory performance, affecting gloss and vividness, etc., to achieve good thixotropy and anti-settling effect, obvious thixotropy effect and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 prepares the hydroxyl acrylic resin of Mn2000

[0017] In the 500ml four-necked reaction flask equipped with stirrer, thermometer, dropping funnel and condenser, add S100# solvent 200g (equivalent to 40wt%), under nitrogen protection, start stirring, be warming up to reflux (about 165 ℃ ), began to drop the mixed liquid 300g (comprising the monomer and the initiator) of the monomer and the peroxide initiator dropwise at a constant speed, wherein the monomer was 9.5g of hydroxyethyl methacrylate and 100g of methyl methacrylate, methyl Butyl acrylate 60g, butyl acrylate 40g, styrene 30g and vinyl tertiary carbonate 40g add up to 279.5g (equivalent to monomer total amount 55.9wt%, wherein, hydroxy acrylate monomer is: hydroxyethyl methacrylate accounts for unit 3.4wt% of the total volume, specifically calculated as 9.5÷279.5=3.4wt%); the initiator is 20.5g of di-tertamyl peroxide (equivalent to 4.1wt%), and solution polymerization is carried out at 160-170°C f...

Embodiment 2

[0018] Embodiment 2 prepares the hydroxyl acrylic resin of Mn3000

[0019] In a 500ml four-necked reaction flask equipped with stirrer, thermometer, dropping funnel and condenser, add xylene solvent 200g (equivalent to 40wt%), under nitrogen protection, start stirring, be warming up to reflux (about 138 ℃ ), began to drip the mixed solution 300g (including monomer and initiator) of monomer and peroxide initiator at a constant speed, wherein the monomer was 5.5g of hydroxyethyl acrylate and 100g of methyl methacrylate, butyl methacrylate Ester 80g, butyl acrylate 58g and styrene 40g add up to 283.5g (corresponding to monomer total amount 56.7wt%, wherein, hydroxy acrylate monomer is: hydroxyethyl acrylate accounts for 1.94wt% of monomer total amount); The agent is 16.5g (equivalent to 3.3wt%) of tert-butyl peroxybenzoate (equivalent to 3.3wt%) for solution polymerization at 135-140°C, and the dropwise addition is completed in about 6 hours, and then kept for 3 hours, cooled and...

Embodiment 3

[0020] Embodiment 3 prepares the hydroxyl acrylic resin of Mn4000

[0021]In the 500ml four-necked reaction flask that stirrer, thermometer, dropping funnel and condenser are equipped with, add butyl acetate solvent 225g (corresponding to 45wt%), under nitrogen protection, start stirring, be warming up to reflux (about 128 ℃), began to drop at a constant speed a mixture of 275g of monomers and peroxide initiators (including monomers and initiators), wherein the monomers were 4.5g of hydroxypropyl acrylate and 80g of methyl methacrylate, methacrylic acid 80g of butyl ester, 65g of butyl acrylate and 30g of styrene totaled 259.5g (equivalent to 51.9wt% of the total amount of monomers, wherein the hydroxyacrylate monomer is: hydroxypropyl acrylate accounts for 1.73wt% of the total amount of monomers); The initiator is tert-butyl peroxybenzoate 15.5g (equivalent to 3.1wt%), and solution polymerization is carried out at 125-130°C, and the dropwise addition is completed in about 5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com