Vibration wheel for vibratory roller

A vibratory roller and vibrating wheel technology, applied in the field of vibrating wheels, can solve the problems of excessive lubricating oil service temperature, slow air convection, limited heat transfer, etc., to achieve good working characteristics and prolong working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

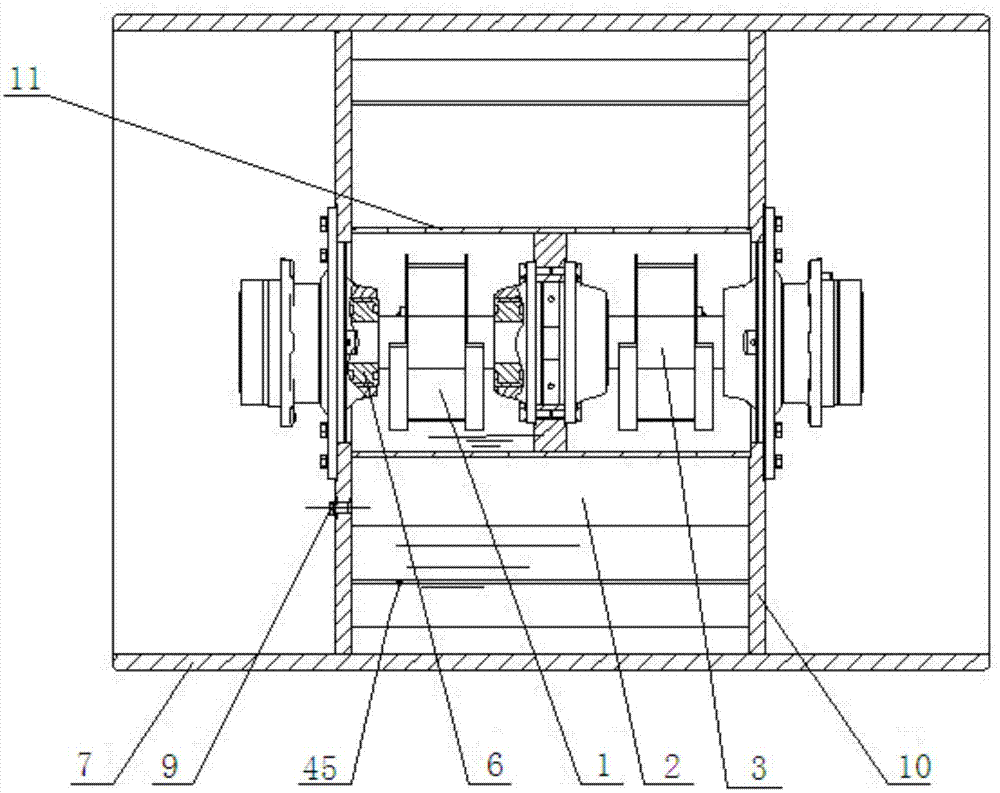

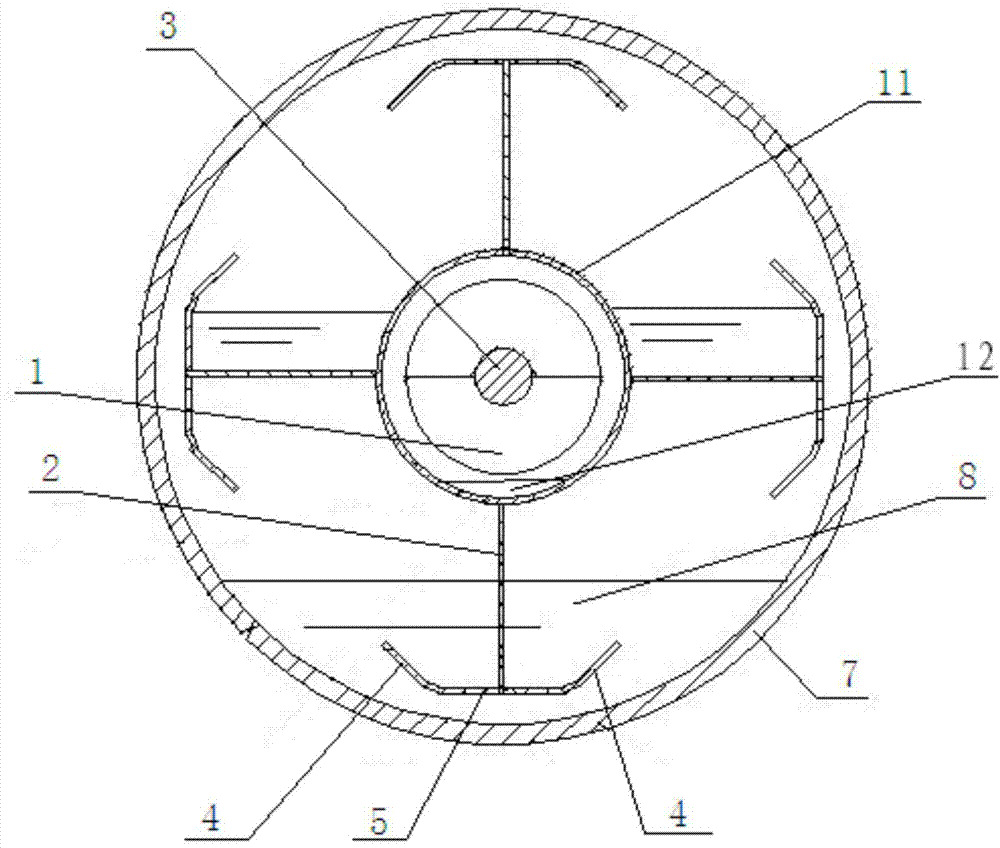

[0013] figure 1 , figure 2 As shown, it relates to a vibrating wheel for a vibratory roller, including an outer ring 7, a web 10 arranged inside the outer ring 7, and an inner ring 11 arranged in the middle of the web 10; the inner ring 11 is provided with a vibration shaft 3 with an eccentric shaft 1, and the two ends of the vibration shaft 3 are fixedly connected to the web 10 through a vibration bearing 6; between the outer ring 7, the inner ring 11 and the web 10 is formed Sealed oil storage chamber 8. Wherein, a plurality of ribs 2 extending into the oil storage cavity 8 are evenly distributed on the outer edge of the inner ring 11 , and a supporting plate 45 is provided at the lower end of the ribs 2 . Wherein, when the bottom end of the supporting plate 45 is between 5-10 cm from the inner wall of the outer ring 5, the supporting plate 45 can better displace the oil in the oil storage chamber 8 when the vibrating wheel is working. The coolant is brought into the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com