Horizontal well bushing shaping repair method and device

A repair method and technology for horizontal wells, applied in earthwork drilling, wellbore/well components, etc., can solve problems such as no shaping effect, insufficient shellless shaping elastic strength, horizontal well casing blockage, etc., and achieve high energy release rate , Guarantee normal production operation, and the effect of large diameter expansion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

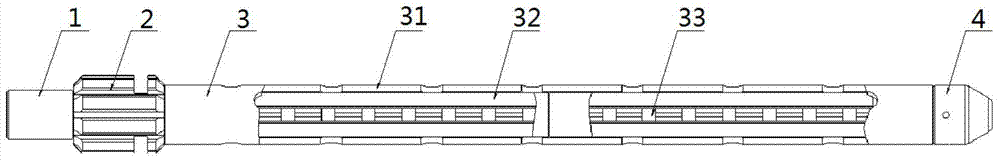

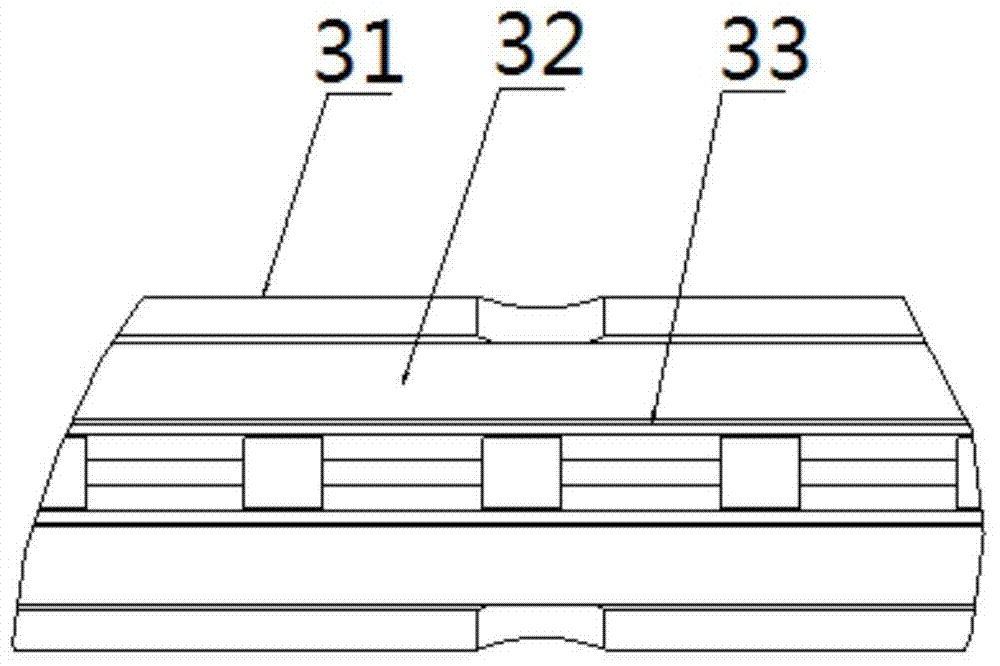

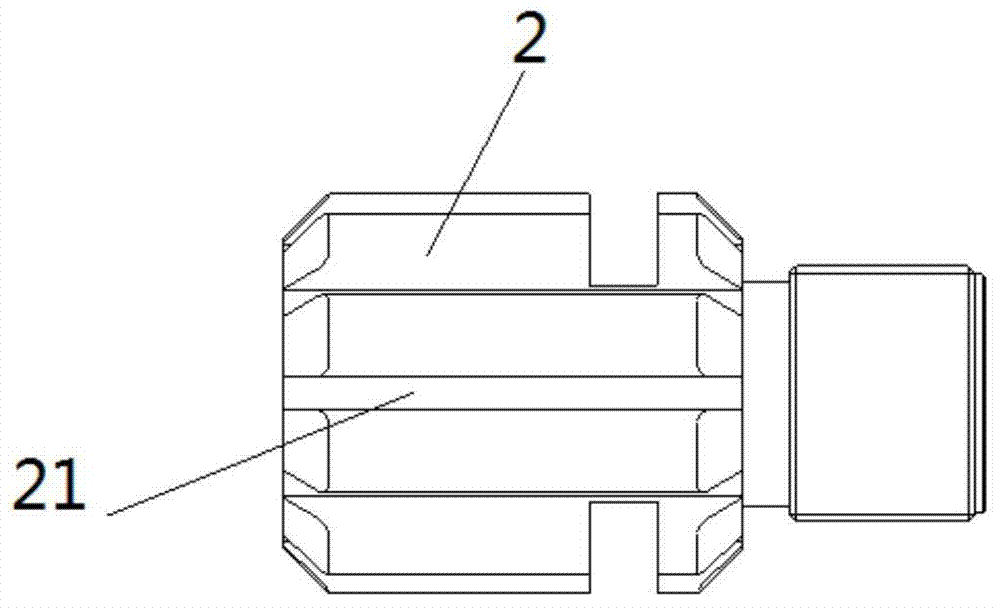

[0048] Such as Figure 1-4 As shown, this embodiment provides a specific structure of a horizontal well casing shaping and repairing device, which includes an igniter 1, an integrated bore gauge 2, a shaping gun assembly 3, and a gun tail or a connecting joint 4 connected in sequence; , the shaping gun assembly includes a shaping gun 31, an energetic material main charge 32, an ignition transmission central tube assembly 33, an integrated bore gauge 2, an intermediate joint and a gun tail 4, and the energetic material main charge 32 is set at the point The central tube assembly 33 for fire transmission is placed inside the shaping gun 31 , and the integrated bore gauge 2 is provided with a pressure relief groove 21 .

[0049] The main charge of this embodiment is composite gunpowder (prescription: epoxy resin 30%, ammonium perchlorate 55%, aluminum powder 14%, burning rate regulator Fe 2 o 3 1%), the outer diameter of the main charge is 66mm, the inner diameter is 25mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com