Control method for coriolis mass flow tube of variable sensor signal setting value

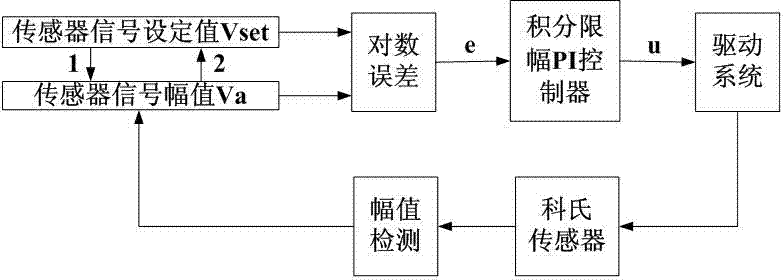

A sensor signal and control method technology, applied in the direction of direct mass flowmeter, mass flow measurement device, etc., can solve the problems of large fluctuation range of sensor signal amplitude, loss of digital drive system, large fluctuation, etc., and achieve the sensor output signal amplitude Stable, reduce signal volatility, adjust flexible and effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

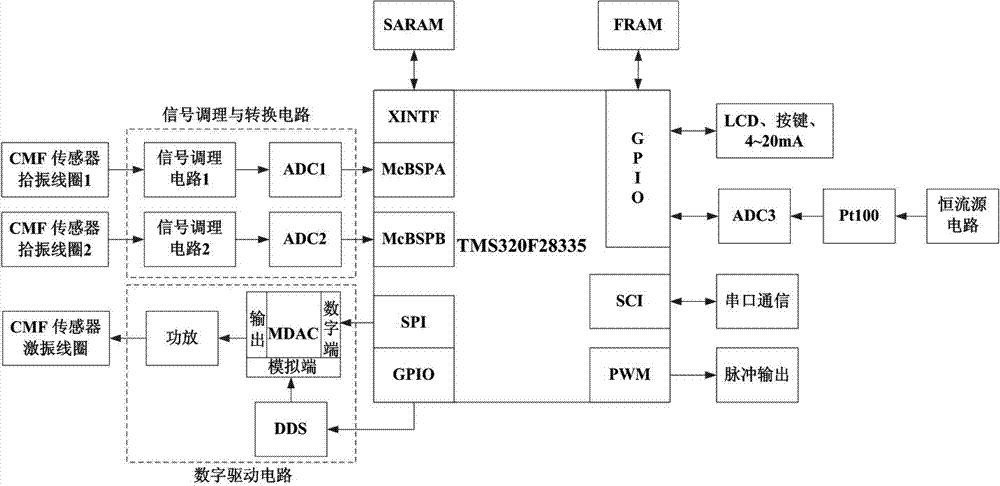

[0031] The block diagram of the hardware structure of the present invention is as figure 1 As shown, including DSP chip, signal conditioning and conversion circuit, digital drive circuit, constant current source circuit, Pt100, ADC3, externally expanded SRAM, externally expanded ferroelectric memory (FRAM), LCD, keys, serial communication, 4~20mA and Pulse output, power module and other components. Among them, the signal conditioning circuit 1, ADC1, signal conditioning circuit 2, and ADC2 form a signal conditioning and conversion circuit, which are connected with the pickup coil 1 and pickup coil 2 of the Coriolis mass flowmeter, and receive, condition and convert the output speed of the pickup coil Signal; DDS, MDAC, and power amplifier form a digital drive circuit to complete the synthesis and output of drive signals.

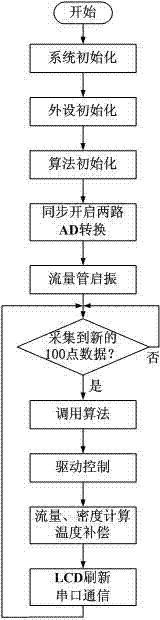

[0032] The working process of the present invention is as figure 2 shown. After the system is powered on, the DSP first completes the initialization of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com