A kind of eucommia gum/natural latex sponge product and preparation method thereof

A technology of natural latex and sponge products, which is applied in the field of eucommia gum/natural latex sponge products and its preparation, can solve the problems of less application and less registration, and achieve the effect of expanding application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of Eucommia gum / natural rubber composite sponge with a ratio of 5 / 95:

[0035] (1) Preparation of mixed glue:

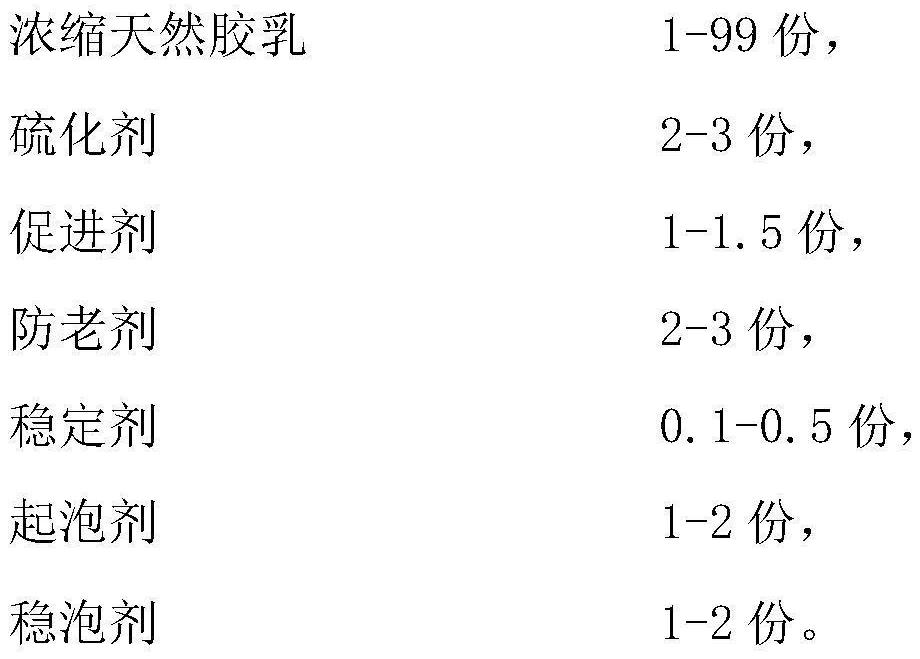

[0036] Calculated by mass

[0037]

[0038] Add Eucommia latex to natural rubber latex and mix evenly, add Pingping and O, stir evenly and remove ammonia to 0.1%, then add other rubber additives, stir for 8-12 hours at 30-35°C, and mature , the ripening time is 24 hours;

[0039] (2) Preparation of gel:

[0040] Calculated by mass

[0041]

[0042] After the mature composite glue is mixed at a speed of 500-1500 rpm and filled with air to quickly foam to a specified volume, it is soaked at a slow speed of 100-200 rpm, and then diluted with double the amount of soft water. The active agent zinc oxide is soaked at a speed of 200-400 rpm at a medium speed for 2 minutes, and finally sodium fluorosilicate and potassium hydroxide are added together, and treated at a speed of 200-400 rpm at a medium speed. After 2 minutes, the foam is finally po...

Embodiment 2

[0046] Preparation of Eucommia gum / natural rubber composite sponge with a ratio of 10 / 90:

[0047] (1) Preparation of mixed glue:

[0048] Calculated by mass

[0049]

[0050] Add Eucommia latex to natural rubber latex and mix evenly, add Pingping and O, stir evenly and remove ammonia to 0.1%, then add other rubber additives, stir for 8-12 hours at 30-35°C, and mature , the ripening time is 24 hours;

[0051] (2) Preparation of gel:

[0052] Calculated by mass

[0053]

[0054] After the mature composite glue is mixed at a speed of 500-1500 rpm and filled with air to quickly foam to a specified volume, it is soaked at a slow speed of 100-200 rpm, and then diluted with double the amount of soft water. The active agent zinc oxide is soaked at a speed of 200-400 rpm at a medium speed for 2 minutes, and finally sodium fluorosilicate and potassium hydroxide are added together, and treated at a speed of 200-400 rpm at a medium speed. After 2 minutes, the foam is finally p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com