Souffle yoghourt and preparation method thereof

A technology of yogurt and cream cheese, which is applied in the fields of milk preparations, dairy products, food science, etc., and can solve the problems of poor stability of souffle and limited eating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

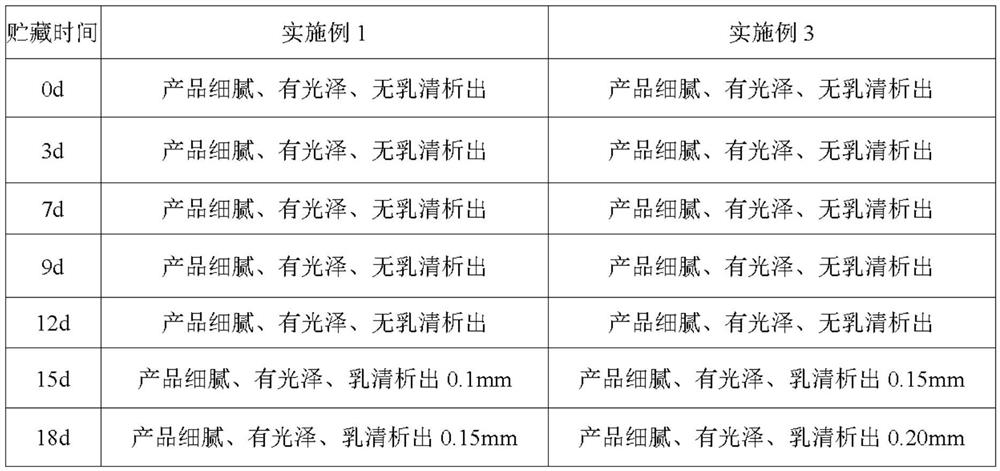

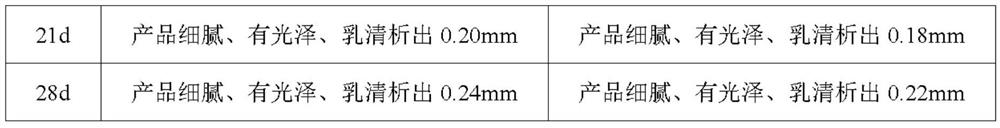

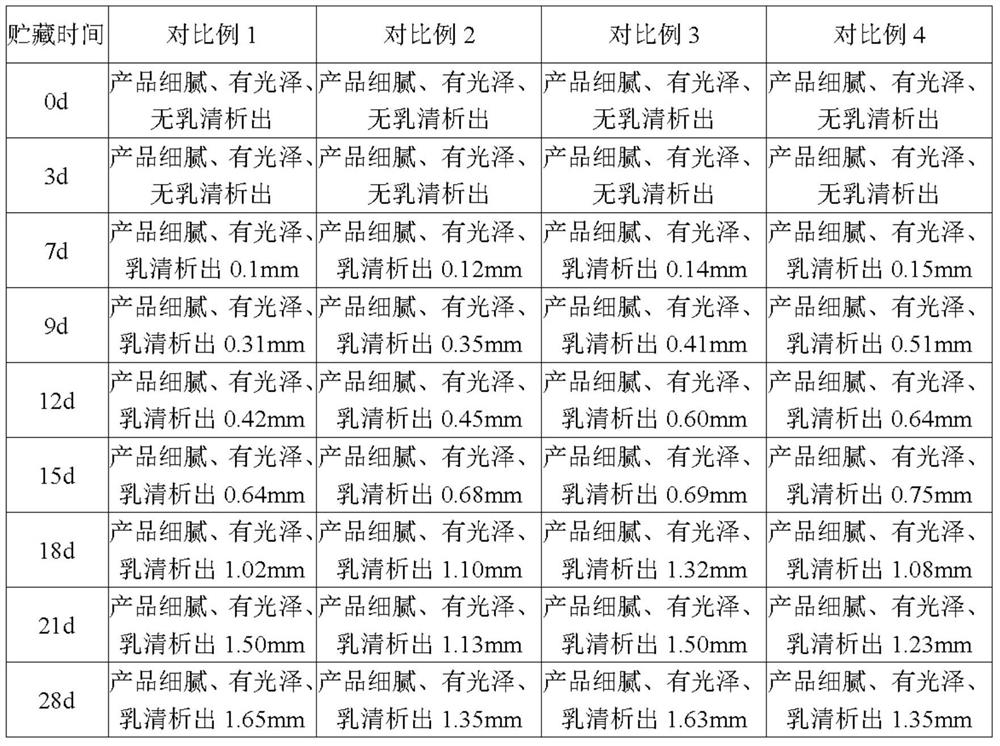

Examples

Embodiment 1

[0057] The preparation of embodiment 1 yellow peach soufflé yoghurt

[0058] 1. The preparation of yellow peach soufflé jam (100kg)

[0059] 1) Chemical material: melt 8kg of cream cheese at a temperature of 50°C to obtain a semi-solid cream cheese slurry;

[0060] 2) Mixing: 21.5kg water, 30kg white granulated sugar, 25kg yellow peach fruit (fruit size 3mm*3mm), 10kg egg yolk powder, 5kg hydroxypropyl distarch phosphate, 0.5kg pectin and step 1) cream cheese slurry for mixing;

[0061] 3) Sterilization: Sterilize the mixture obtained in step 2), wherein the sterilization condition is to treat at 85° C. for 10 minutes;

[0062] 4) Cooling down: cooling the sterilized mixed material in step 3) to below 30° C. to obtain yellow peach soufflé jam.

[0063] 2. Preparation of Yogurt Base

[0064] Raw milk is standardized, preheated to 65°C, homogenized (homogeneous pressure is 40bar for the second stage, 180bar for the first stage), sterilized (93°C, 10min), inoculated, and ferm...

Embodiment 2

[0068] Preparation of Example 2 Yellow Peach Soufflé Yogurt

[0069] 1. The preparation of yellow peach soufflé jam (100kg)

[0070] 1) Chemical material: melt 8kg of cream cheese at a temperature of 50°C to obtain a semi-solid cream cheese slurry;

[0071] 2) Mixing: 21.5kg water, 30kg white granulated sugar, 25kg yellow peach fruit (fruit size 3mm*3mm), 10kg egg yolk powder, 5kg hydroxypropyl distarch phosphate, 0.5kg pectin and step 1) cream cheese slurry for mixing;

[0072] 3) Sterilization: Sterilize the mixture obtained in step 2), wherein the sterilization condition is to treat at 85° C. for 10 minutes;

[0073] 4) Cooling down: cooling the sterilized mixed material in step 3) to below 30° C. to obtain yellow peach soufflé jam.

[0074] 2. Preparation of Yogurt Base

[0075] Raw milk is standardized, preheated to 65°C, homogenized (homogeneous pressure is 40bar for the second stage, 180bar for the first stage), sterilized (93°C, 10min), inoculated and fermented unt...

Embodiment 3

[0079] The preparation of embodiment 3 raspberry soufflé yoghurt

[0080] 1. The preparation of raspberry soufflé jam (100kg)

[0081] 1) Chemical material: melt 8kg of cream cheese at a temperature of 55°C to obtain a semi-solid cream cheese slurry;

[0082] 2) Mixing: 18.5kg water, 30kg white sugar, 28kg raspberry fruit (fruit size 8mm*8mm), 10kg egg yolk powder, 5kg hydroxypropyl distarch phosphate, 0.5kg pectin and step 1) of the cream cheese slurry;

[0083] 3) Sterilization: Sterilize the mixture obtained in step 2), wherein the sterilization condition is to treat at 95°C for 40 minutes;

[0084] 4) Cooling down: cooling the sterilized mixed material in step 3) to below 30° C. to obtain raspberry soufflé jam.

[0085] 2. Preparation of Yogurt Base

[0086] Raw milk is standardized, preheated to 65°C, homogenized (homogeneous pressure is 40bar for the second stage, 180bar for the first stage), sterilized (97°C, 20min), inoculated and fermented until the titrated acidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com