Universal mechanically enclosed test bench for bevel gearboxes

A gearbox and closed technology, which is applied in the field of mechanical closed test benches for bevel gearboxes, can solve problems such as poor working conditions of gearboxes, and achieve the effects of increasing the reuse rate, convenient use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

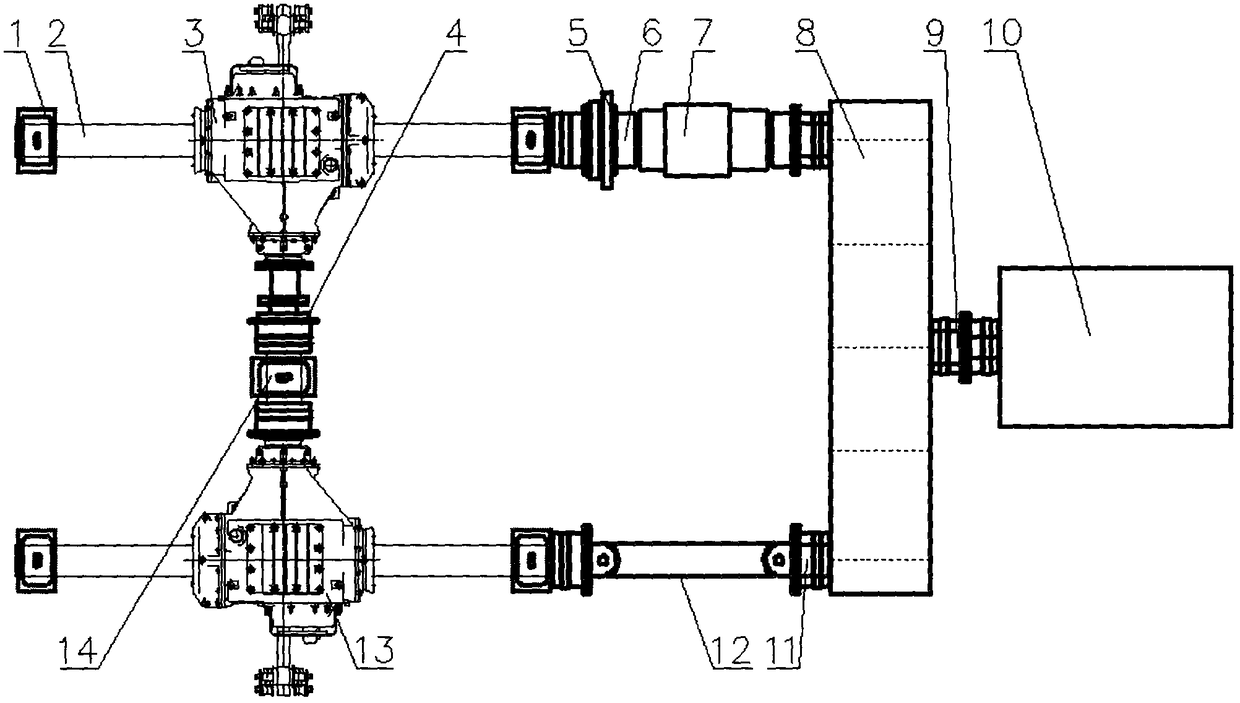

[0010] The specific implementation is: taking the tested gearbox 3 as the core, first arrange the pinion shafts of the tested gearbox 3 and the companion gearbox 13 face to face, and pass the torque meter 1 (part number 4), the coupling and the bearing seat Two (item number 14) connect the pinion shafts of the two; the two symmetrical output shafts of the connecting gearbox 8 are respectively connected to the two large gear shafts of the conical gearbox used in the test, and the large gear shaft of the tested gearbox is connected to The output shaft of the gearbox is connected to the bearing seat, another torque meter 2 (key 5), coupling 1 (key 6) and hydraulic torque loader 7 in turn, and test the large gear shaft of the gear box with the connecting gear box The output shafts are connected with the bearing seat, the cardan shaft 12 and the coupling three (part number 11) in sequence; the two torque meters connected to the shaft ends of the large and small gears of the tested ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com