Object sampling method and object sampling equipment capable of distinguishing die hole

A technology for sampling equipment and die holes is applied in the field of article sampling method and sampling equipment for automatically distinguishing die holes, which can solve the problems of reduced accuracy, inability to distinguish the corresponding relationship between articles and production equipment, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

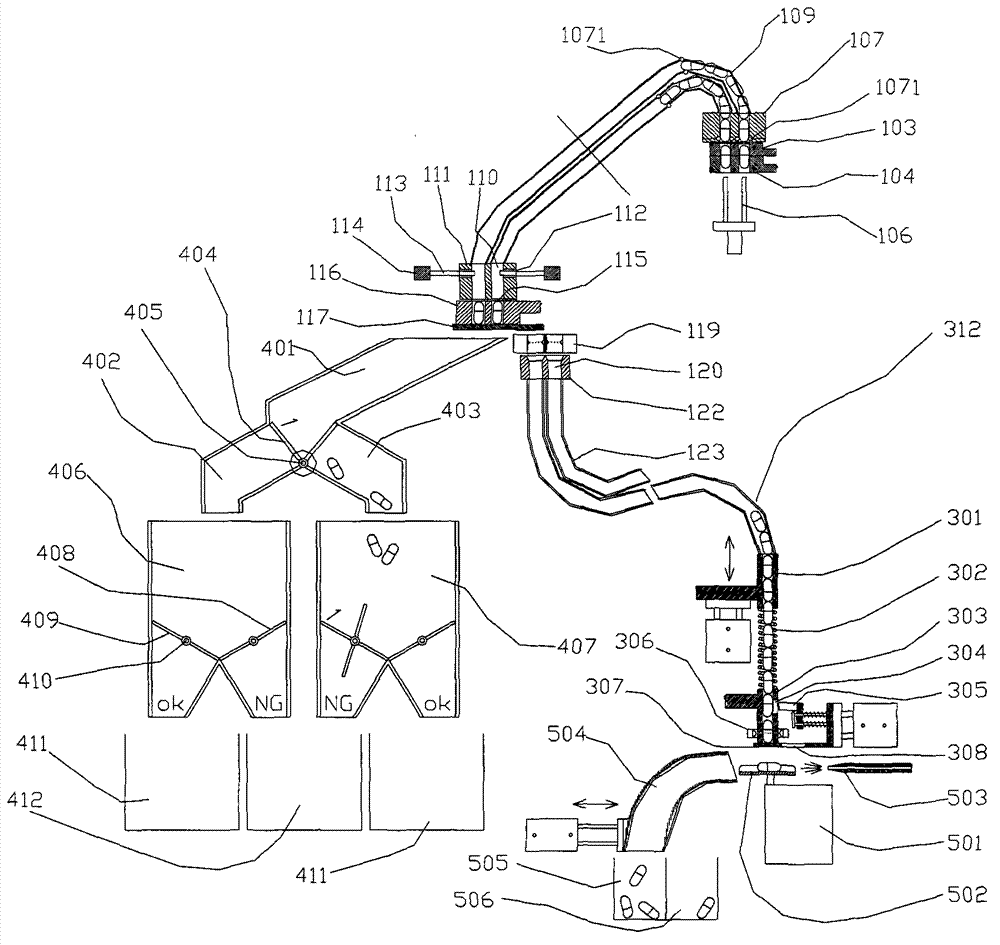

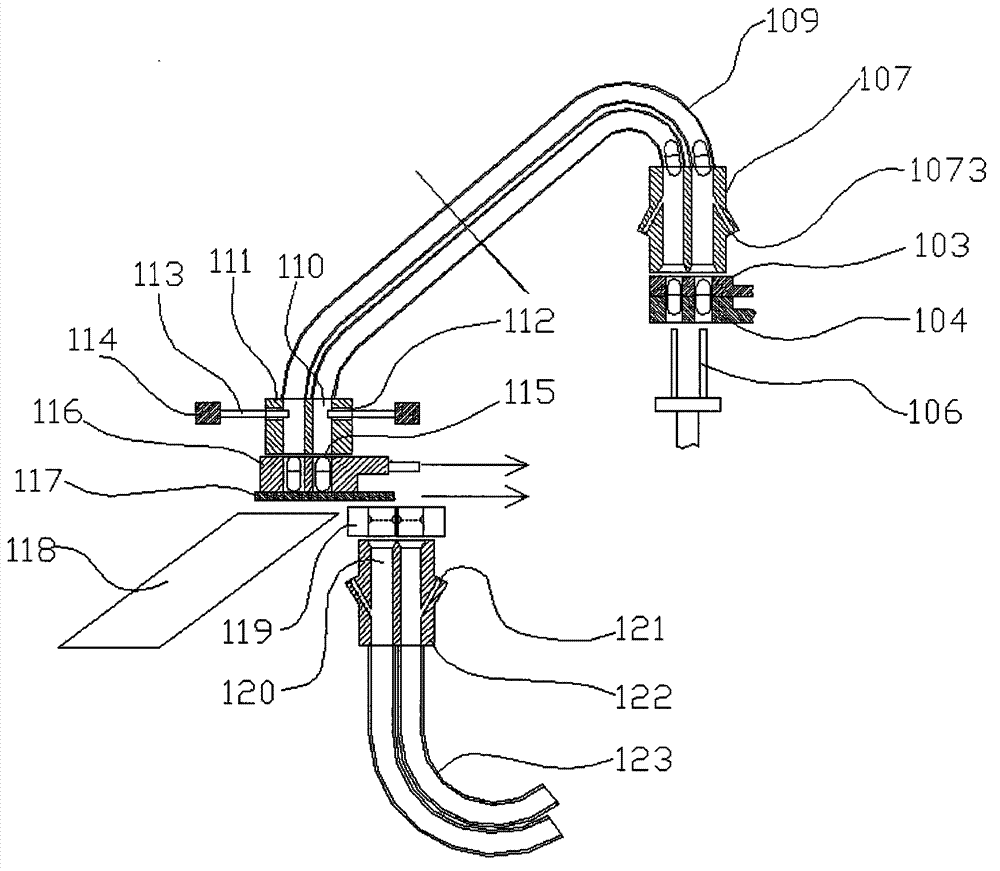

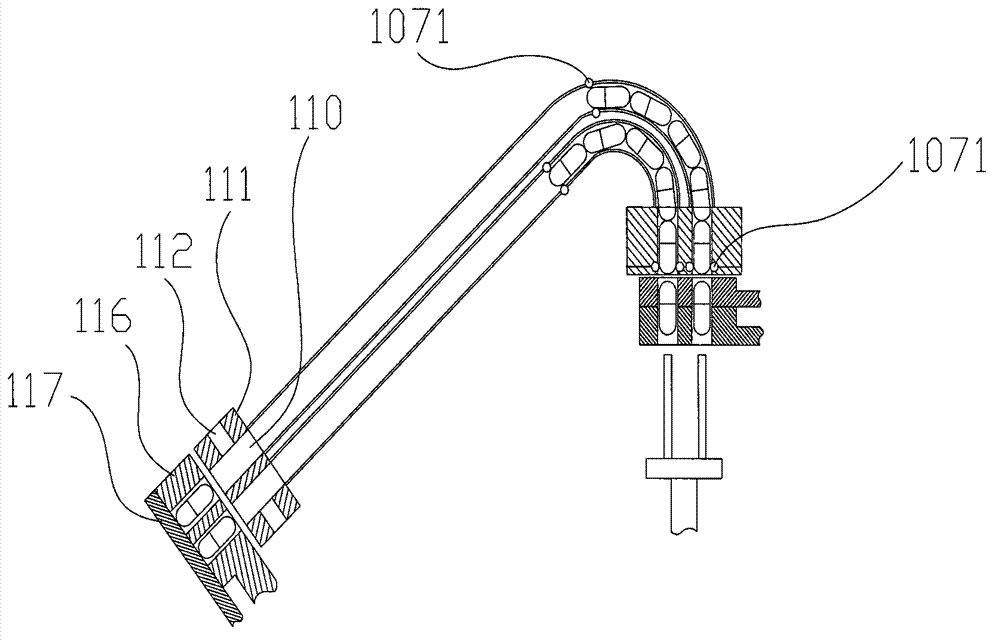

[0060] Embodiment 1 of the present invention discloses an article sampling device that can distinguish die holes, which is used to sample the articles in each die hole on the capsule filling machine, such as Figure 1A As shown, the capsule filling machine includes an upper module 103 of the filling machine, a lower module 104 of the filling machine, a die hole 105 arranged on the upper module 103 of the filling machine and a lower module 104 of the filling machine, and a capsule discharge rod 106 arranged under the lower module 104 of the filling machine . The upper module 103 of the filling machine corresponds to the die hole 105 on the lower module 104 of the filling machine, and the ejection rod 106 is used to eject the capsule-shaped article in the die hole 105 .

[0061] The sampling equipment includes: a capsule collection tube 109 for conveying the items output from the corresponding die hole 105, a capsule stop hole 112 arranged on the side of the capsule collection tu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap