Supporting structure for coaxial light-small type reflecting mirror with high thermal stability

A technology with high thermal stability and mirror support, which is applied in the aerospace field, can solve problems such as high technical level requirements, system failure, and poor interchangeability, and achieve low assembly process requirements, ensure uniform deformation, and change surface accuracy small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be further described below in conjunction with the drawings.

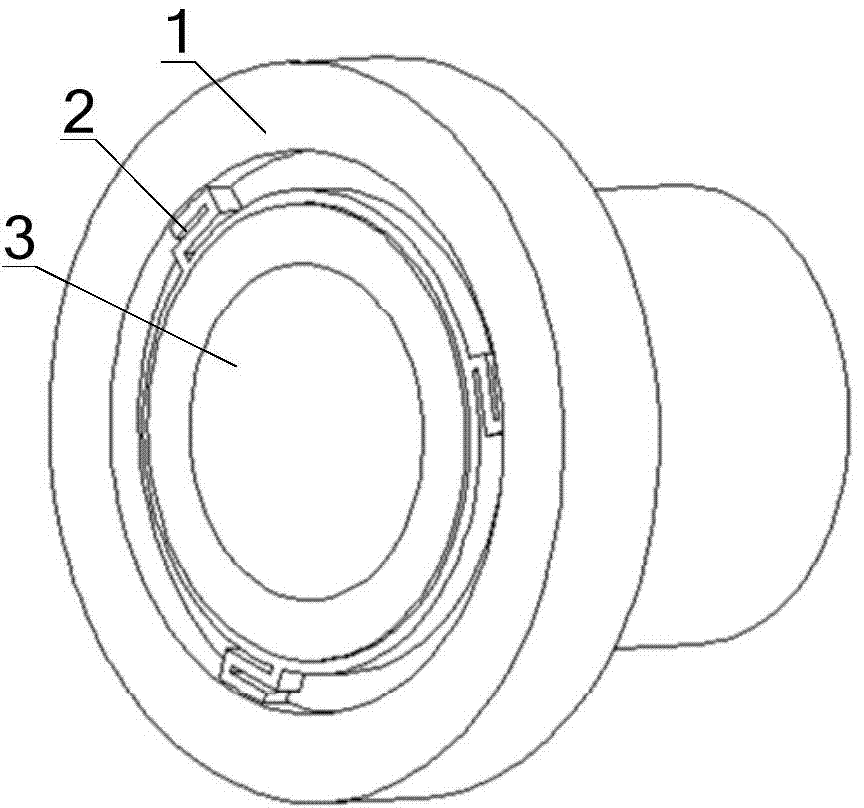

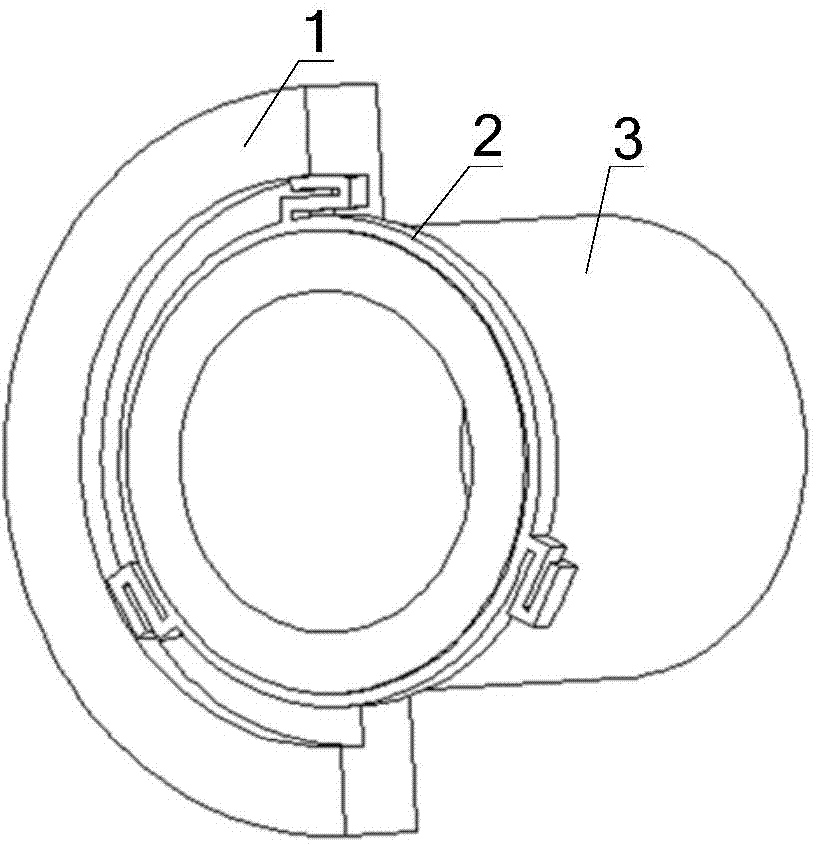

[0020] See attached figure 1 And figure 2 , The coaxial light and small high thermal stability mirror support structure includes a mirror 1, a flexible joint 2 and a mandrel 3; the outer ring 201 of the flexible joint 2 and the mirror 1 are glued and fixed, and the inner ring of the flexible joint 2 202 is glued and fixed with the mandrel 3, the reflector 1, the flexible joint 2 and the mandrel 3 are coaxial, and the outer ring 201 of the flexible joint 2 is between the reflector 1

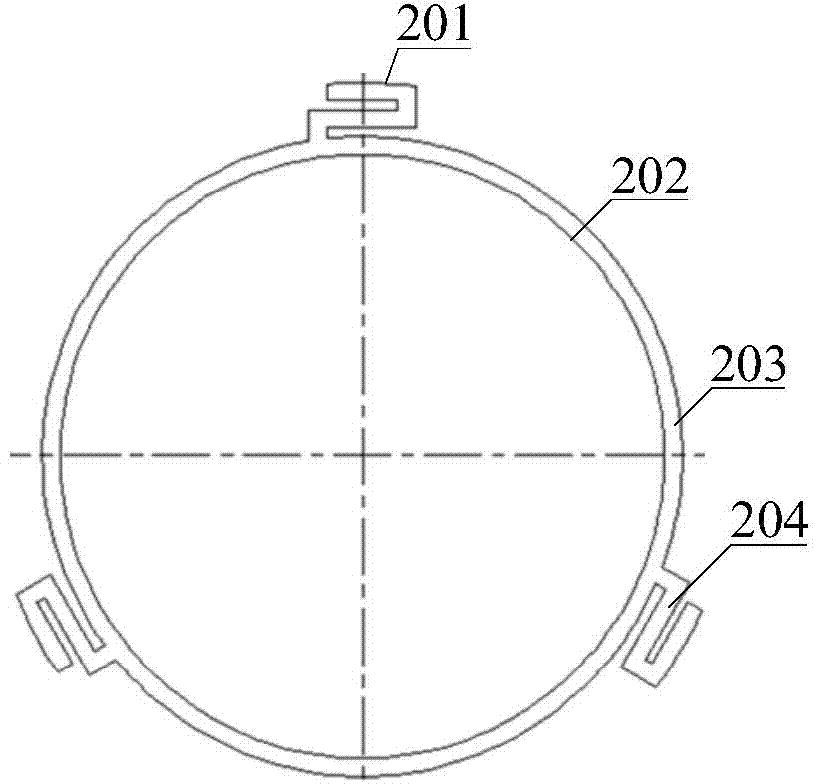

[0021] See attached image 3 , The flexible joint 2 is a circular ring structure, including a ring body 203 and a plurality of single-arm structures 204, the plurality of single-arm structures 204 are evenly distributed on the outer wall of the ring body 203, and the single-arm structure 204 is a double-layer flexible unloading structure, and two grooves are arranged radially, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com