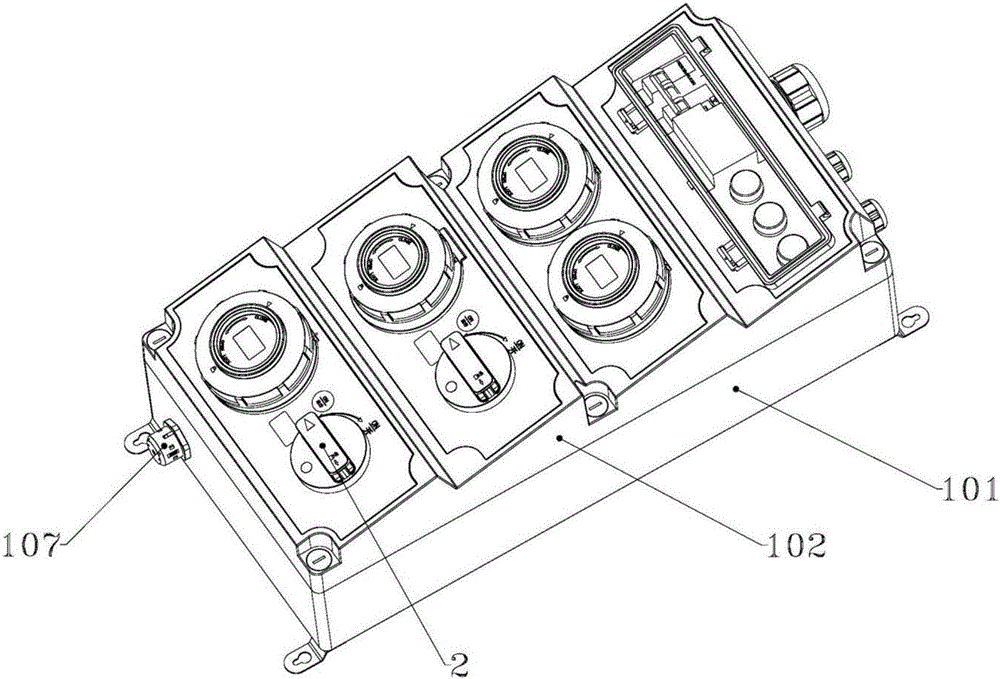

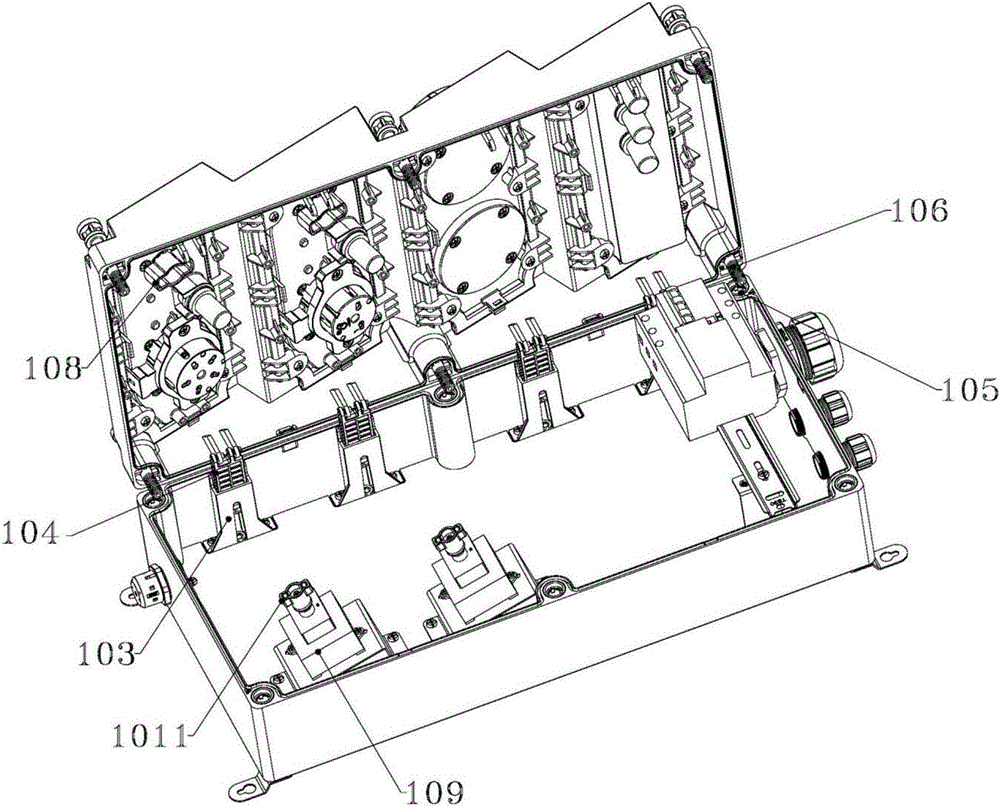

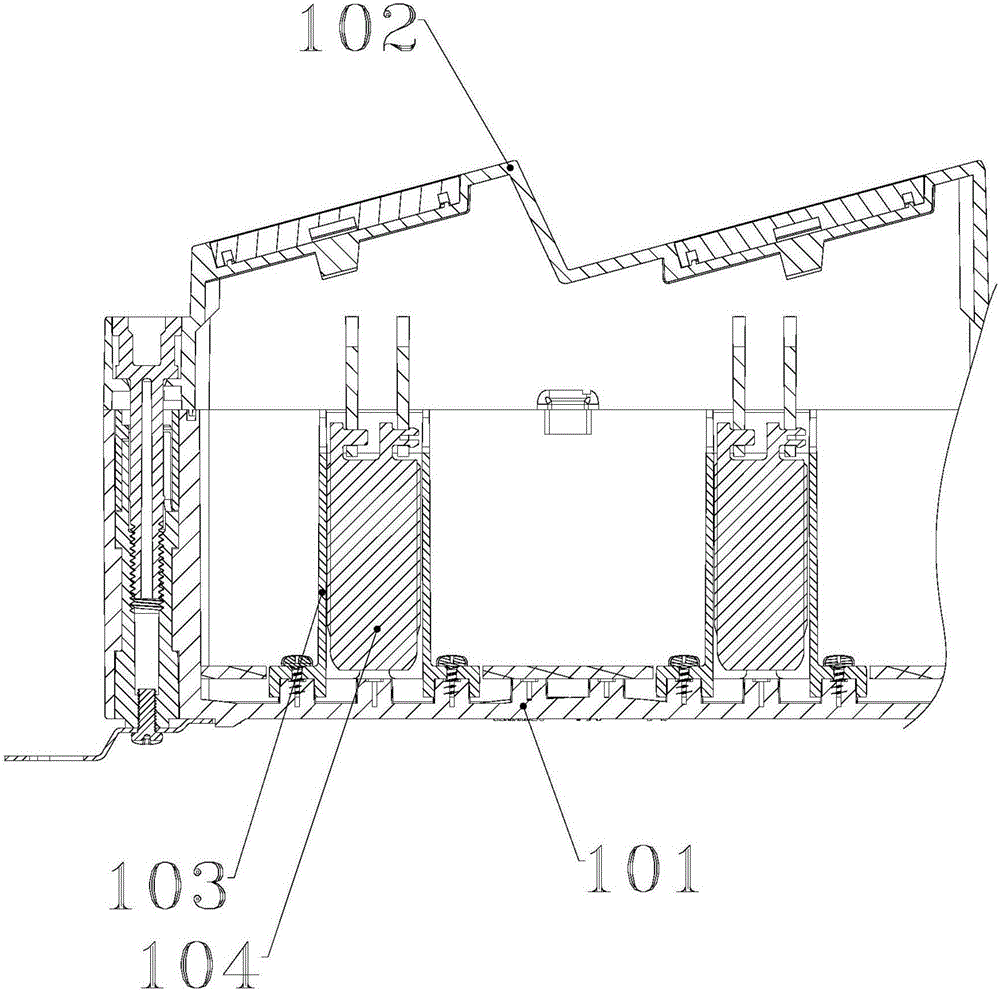

distribution box

A distribution box and hinge technology, applied in electrical components, substation/switch layout details, etc., can solve the problems of troublesome processing, poor sealing effect, etc., to achieve the effect of convenient installation, convenient maintenance and installation of internal parts, and ensure drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0054] The difference between the plane operation panel in the second embodiment and the first embodiment is that the model is different, and the difference of the model is mainly reflected on its inner core 4, the first embodiment is 63A5P, and the second embodiment is 32A4P, but because the outer core 4 of them The diameters are similar, so the structures of their operation panel 1 and inner cover mounting plate 5 can be completely the same, so that the versatility of the accessories of the plane operation panel of the present invention is improved.

[0055] like Figure 10-11 In the third embodiment shown, the main difference between the third embodiment and the first and second embodiments lies in its position-limiting structure:

[0056] The position-limiting structure includes an inner ring 91 and an outer ring 92 surrounding the inner core 4, the outer ring 92 is installed on the inner ring 91, and the inner ring 91 is a rotation track, and a section of the outer ring w...

Embodiment 3

[0059] The design of the limiting structure in the third embodiment is mainly aimed at socket inner core components with a small outer diameter. The present invention changes the structure of the limiting structure so that different types of socket inner core components can share one type of operation panel and The inner cover mounting plate and the like are conducive to improving the versatility of the accessories of the plane operating panel of the present invention and reducing the cost as much as possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com