Axial locking mechanism of rolling thrust bearing of vertical motor

A thrust bearing and axial locking technology, used in electric components, electrical components, electromechanical devices, etc., can solve the problems of lock nut failure, falling off, accidents, etc., to improve the axial bearing capacity, reliable performance and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

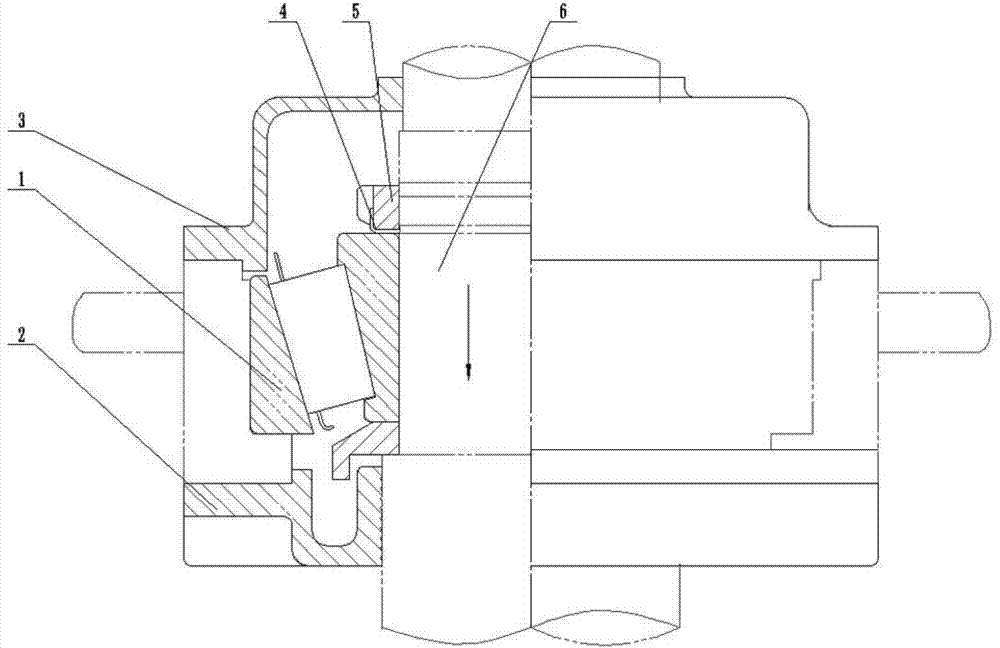

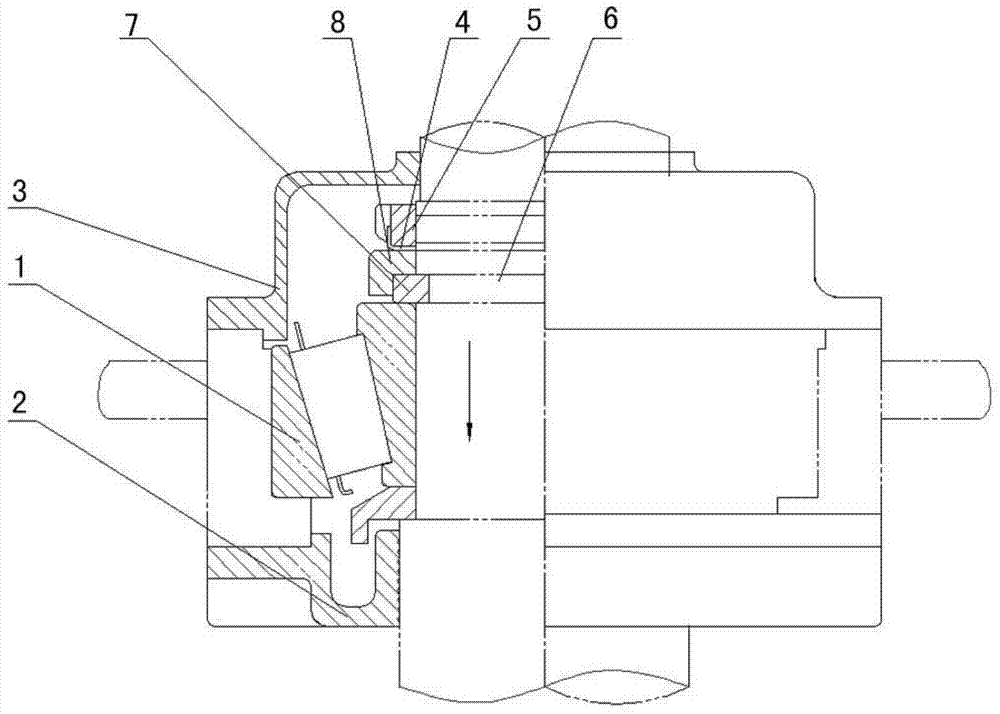

[0008] attached figure 1 It is a schematic diagram of the axial locking mechanism of a vertical motor rolling thrust bearing in the prior art. In the figure, 1 is a rolling thrust bearing, 2 is a bearing inner cover, 3 is a bearing outer cover, 4 is a stop washer, and 5 is a lock nut. 6 is a rotating shaft. It can be seen from the figure that the prior art vertical motor rolling thrust bearing axial locking mechanism usually uses a stop step, a stop washer 4 and a lock nut 5 to fix it on the rotating shaft 6 . During specific installation, a stop step is set on the motor rotating shaft 6, the rolling thrust bearing sleeve 1 is installed on the rotating shaft 6 and is close to the stop step, and then the stop washer 4 is put on and fastened with a lock nut 5, and then , the bearing inner cover 2 and the bearing outer cover 3 are respectively installed on both sides of the rolling thrust bearing. However, during the operation of the motor, the load will generate a vertical dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com