Rigid-flex board and its cover film window-opening grounding method

A technology of flexible and rigid boards and grounding methods, which is applied in the manufacture of multilayer circuits, electrical components, and printed circuits. It can solve the problems of poor tape precision, missing stickers, and low efficiency, so as to avoid manpower and material resources and improve product reliability. The effect of high reliability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

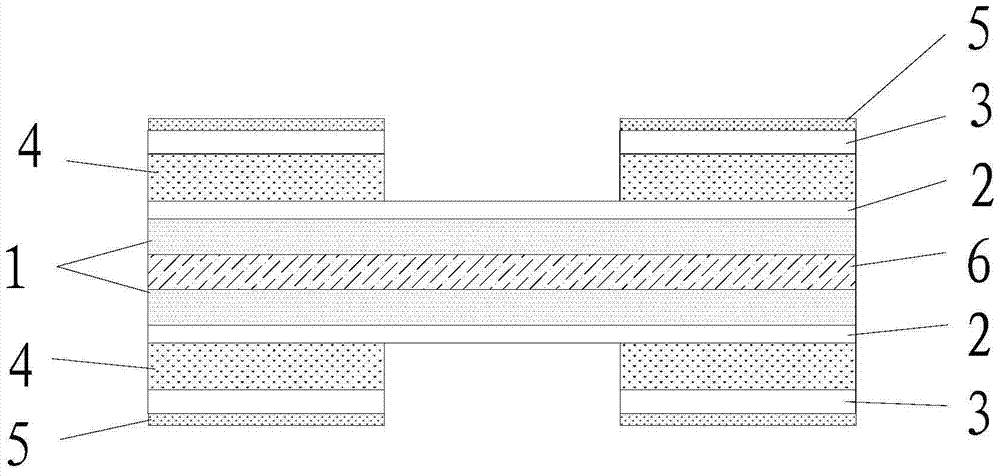

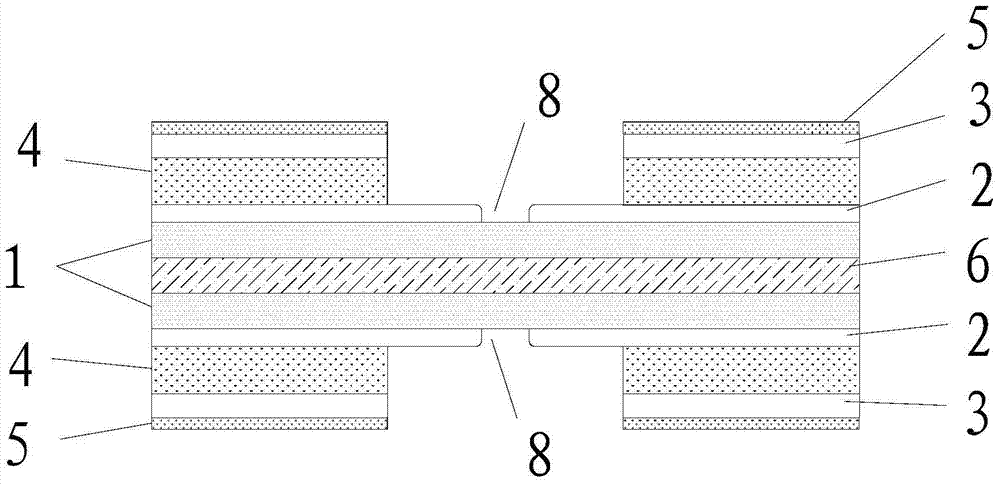

[0026] In order to describe in detail the technical content, the achieved objectives and effects of the present invention, the following description will be given in conjunction with the embodiments and accompanying drawings.

[0027] The most critical idea of the present invention is that the grounding position of the inner cover film is used without windowing treatment first, and the windowing treatment step is placed after the solder mask spraying step is completed, and the laser is used to target the bottom of the hard board substrate slot The inner cover film is grounded and opened, and the inner cover film is burned by a laser to form a ground window and expose the inner circuit of the FPC, and an electromagnetic shielding layer is attached to form a ground connection.

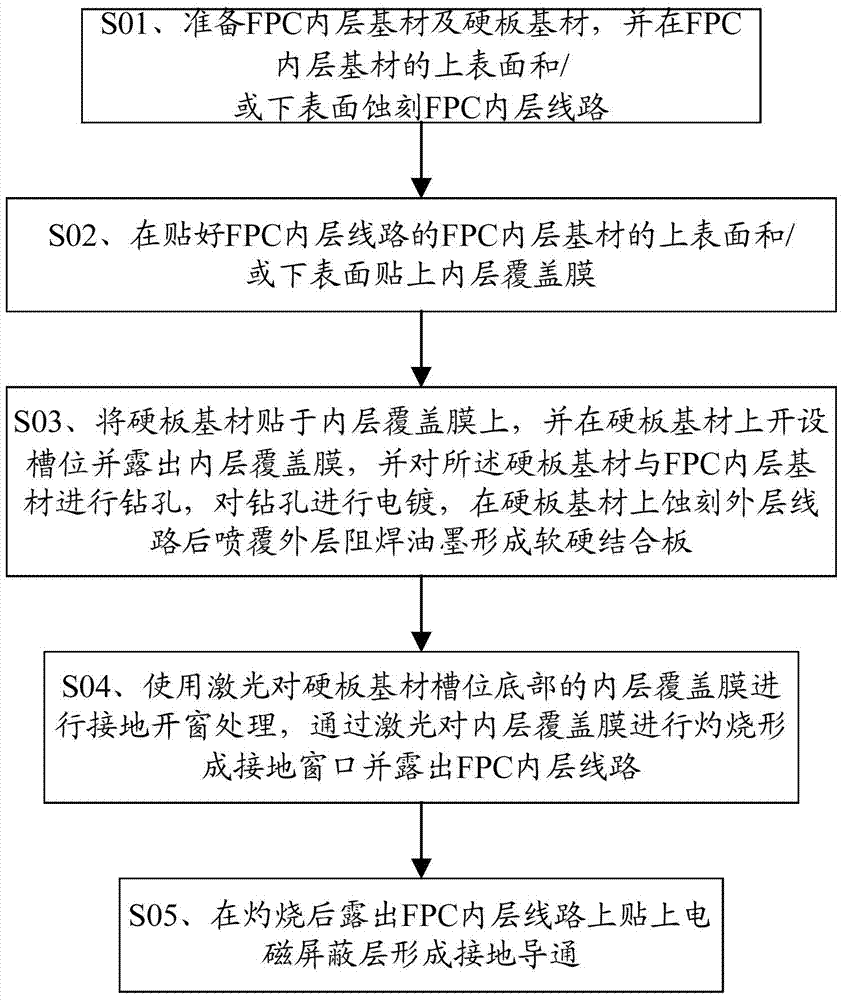

[0028] Please refer to figure 1 , A method for opening a window of the cover film of a flexible and hard board, including the following steps:

[0029] S01. Prepare FPC inner layer substrate and hard board su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com