Sliding rail support

A slide rail and front bracket technology, which is applied in the field of slide rails, can solve the problems of damage, arc-shaped structure with low bite force, looseness, etc., and achieve the effect of reducing the cost of use, not easy to loosen, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

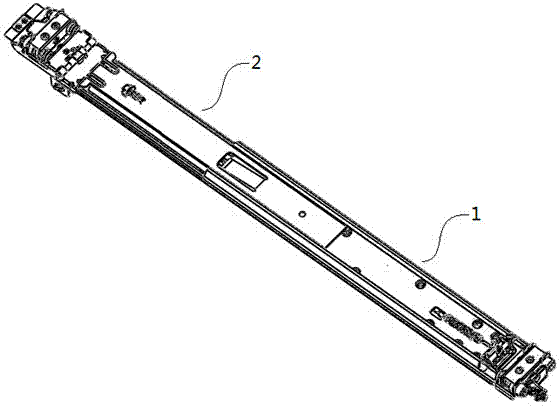

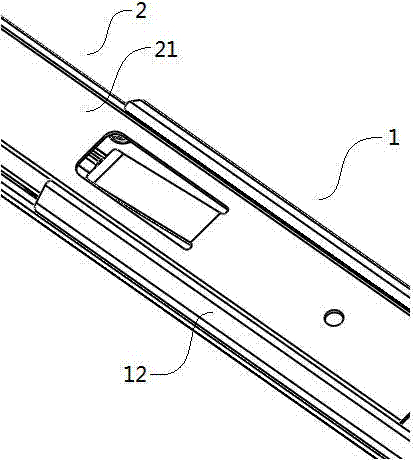

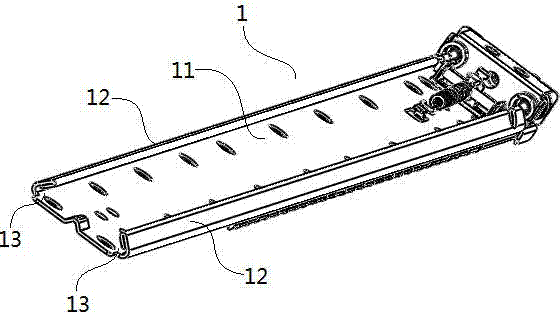

[0020] see Figure 1-5 As shown, a slide rail bracket is composed of a front bracket 1 and a rear bracket 2. The front bracket 1 includes a first main board 11, and the upper and lower edges of the first main board 11 are bent inward to form side plates. 12. The side board 12 and the first main board 11 form two triangular chute 13, the two side boards 12 have an inner splayed structure, the rear bracket 2 includes a second main board 21, and the first The edges of the upper and lower sides of the two main boards 21 are all bent inwardly to form slides 22, and the two slides 22 are in an outer splayed structure; the rear bracket 2 is movably sleeved on the slide 22 In the chute 13 of the front bracket 1, the inner splayed structure of the front bracket 1 and the outer splayed structure of the rear bracket 2 are closely matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com